Waste copper recasting process

A casting process and process technology, applied in the field of scrap copper re-casting process, can solve problems such as inclusions

Inactive Publication Date: 2007-10-17

安徽威龙再制造科技股份有限公司

View PDF0 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The purpose of the present invention is to provide a casting process method of waste miscellaneous copper by adding rare earth elements to solve the process quality problems such as inclusions, porosity and shrinkage cavity in the traditional recovery of miscellaneous copper casting technology, and to improve the high wear resistance of castings, Heat resistance and corrosion resistance

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example 2

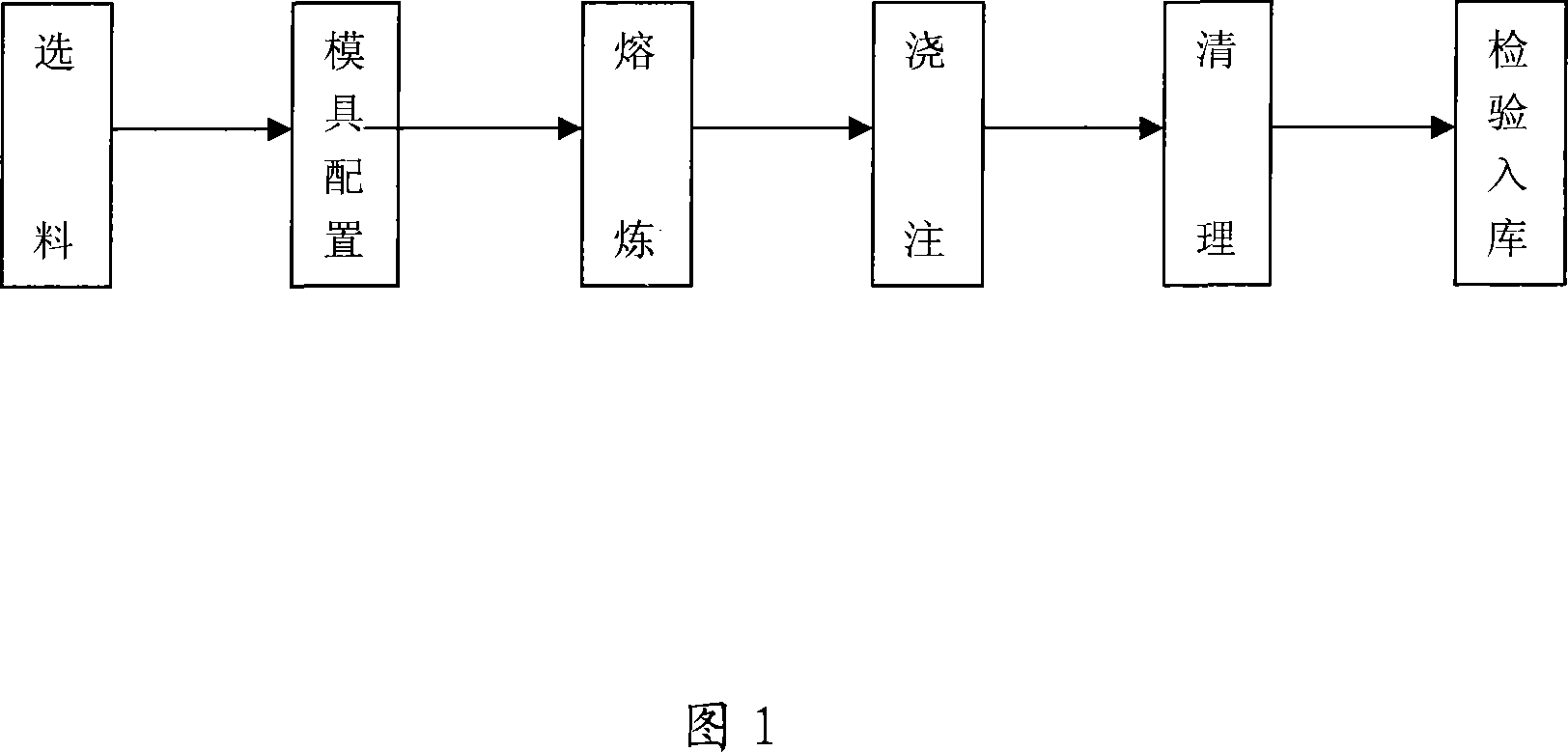

[0015] Example 2, ZCuA18Mn13Fe3Ni2 rare earth aluminum bronze alloy, the casting process is: material selection—→mold configuration—→smelting—→casting—→cleaning—→inspection and storage; the rare earth content in the rare earth alloy copper casting is 0.09% to 0.12%, The allowable iron content is 1.0% to 2.0%, the lead content shall not exceed 3%, and the phosphorus content is allowed to increase to 1.5%.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The present invention discloses a re-foundry technique and method of waste copper used for producing copper alloy cast formed parts by utilizing waste copper. The main method in accordance with the present invention comprises selecting waste and old copper scrap such as red copper and brass and right amount of rare-earth alloy elements; heating them to 1100-1200 DEG C at an intermediate frequency electric stove, adding alloy element and rare earth of 0.03%-0.5% after a thoroughly stirring, performing an affinage and deterioration processing, straring casting after achieving the preceptive casting temperature, and finally, warehousing after a cleaning and check-up. Casting parts produced by adopting said technological process exhibit high surface brightness, compact internal organizing, without gas cavities, inclusion and abscess air holes therein, which all data entirety achieve performance levels of casting parts of the same breed variety, in china and overseas.

Description

technical field [0001] The invention relates to a recasting process of scrap copper by adding rare earth elements, which can improve the performance of copper alloy castings produced by using scrap copper. Background technique [0002] With the advancement of domestic production technology, the requirements for equipment are becoming more and more stringent. Among them, the demand for copper parts has increased significantly in recent years, and the amount of scrap copper has also increased day by day. my country's copper resources are relatively scarce, and the international copper price has remained high. The recycling of waste copper is in line with my country's development strategy. Due to the inability to control factors such as inclusions, porosity, and shrinkage cavities in the traditional recycled copper casting process, the performance of the castings is not high, and it cannot be used on equipment that has high performance requirements for copper parts, or even i...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22B15/14B22D21/00

Inventor 凤宝国孙晓辉秦思俊杨礼彬

Owner 安徽威龙再制造科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com