Steel piece cyanide-free copper plating method adopting applied magnetic field

A technology for cyanide-free copper and steel plating, applied in the field of cyanide-free copper plating, can solve the problems of affecting the performance of the coating, the coarse grains of the coating, and the low production efficiency, and achieve the effects of fast coating deposition, uniform grains, and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] The cyanide-free copper plating method of the iron and steel parts disclosed in this embodiment is carried out in the following steps:

[0015] Step 1: 1. Use 320 mesh and 600 mesh sandpaper to polish the steel statue to be plated successively to make the surface of the substrate smooth and flat, and remove the obvious burrs and oxide layer on the surface of the substrate; 2. Soak the polished statue to be plated in 70 Degreasing is carried out in a chemical degreasing solution at ~90°C for 20 minutes. The composition of this chemical degreasing solution is: sodium hydroxide 10-15g / L, sodium carbonate 20-30g / L, sodium silicate 50-70g / L, Sodium phosphate 10-15g / L; 3. At a temperature of 70°C-80°C and a current density of 2A / dm2-4A / dm2, use the electrolytic degreasing fluid to perform cathodic electrolytic degreasing on the statue of the steel parts to be plated for 1 minute. Then carry out anode electrolytic degreasing for 30 seconds. The composition of this electrolytic...

Embodiment 2

[0019] The difference between this embodiment and the first embodiment is that the electroplating time is 45 minutes. Others are the same as in Embodiment 1.

[0020] Observe the surface of the copper-plated statue with the naked eye and a magnifying glass. The surface is covered by the coating, and the coating has a small amount of impurities.

Embodiment 3

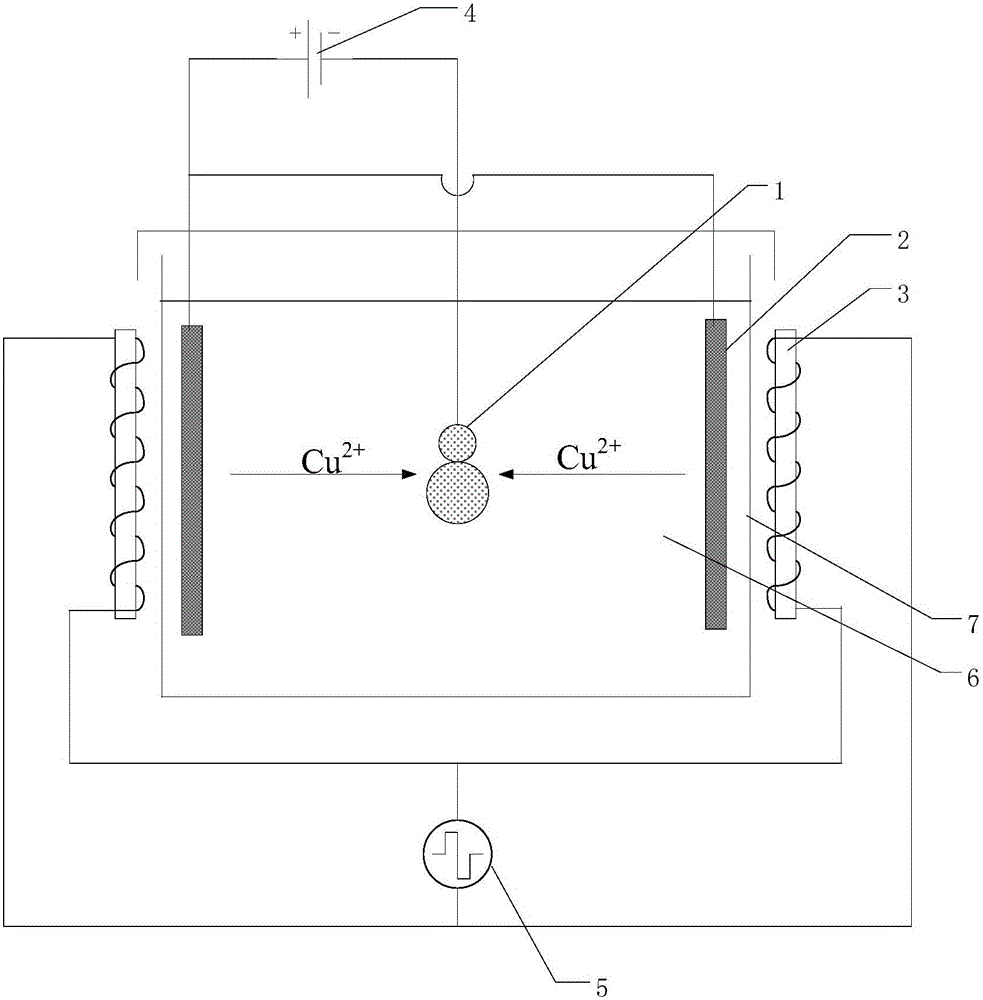

[0022] The difference between this embodiment and Embodiment 1 is that the magnetic field applied outside the electroplating bath is a pulsed magnetic field, the magnetic induction of the pulsed magnetic field is 80-120 gauss, and the direction of the pulsed magnetic field is the same as that of the copper ions in the electroplating solution. The direction of movement is vertical, with a positive pulse of 20 to 30 seconds and a negative pulse of 5 to 15 seconds as a cycle, and the cycle is carried out until the total plating time is 5 to 15 minutes. Others are the same as in Embodiment 1.

[0023] Observe the surface of the copper-plated statue with the naked eye and a magnifying glass. The coating is bright and uniform without impurities and bubbles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com