PBT (polybutylene terephthalate) enhanced flame-retardant laser printing material and preparation method thereof

A laser printing and PBT resin technology, applied in the field of PBT reinforced flame retardant laser printing materials and their preparation, can solve the problems of easy decomposition, discoloration, high requirements, etc., and achieve the effect of clearly visible fonts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A PBT enhanced flame-retardant laser printing material, its raw material includes the following materials by weight:

[0037] 45 parts of PBT resin

[0038] PBT laser powder 2 parts

[0039] Flame retardant 15 parts

[0040] Antioxidant 0.2 parts

[0041] Flow aid 0.2 parts

[0042] Release agent 0.1 parts

[0043] Toughener 8 parts

[0044] Glass fiber 29.5 parts

[0045] The PBT laser powder is manufactured by Sanlaser TM 9015 laser powder, laser marking powder JLJ-36, Merck 8835# radium engraving powder are mixed, the mixing mass ratio of the three is: 0.1:1:1;

[0046] Laser marking aid (laser marking powder) JLJ-36; Laser type: CO2 laser, fiber laser, Nd:Q switch laser; Recommended polymer: PC.PBT.PA.PP.PE.TPE; Color marking: White; pigment color: black; particle size <15μm.

[0047] Merck 8835# radium carving powder is 8835# radium carving powder for Merck black material;

[0048] The Sanlaser TM 9015 laser powder is an organic metal complex, laser dir...

Embodiment 2

[0071] In embodiment 2, described PBT laser powder is made of Sanlaser TM 9015 laser powder, laser marking powder JLJ-36, and Merck 8835# radium engraving powder are mixed, and the mixing mass ratio of the three is: 0.2:1:2.

Embodiment 3

[0072] In Example 3, Sanlaser TM The mixing mass ratio of 9015 laser powder, laser marking powder JLJ-36 and Merck 8835# radium engraving powder is 0.5:5:1.

[0073] The materials of each embodiment are under the black base, and the white characters printed by laser are clear and not easy to wear.

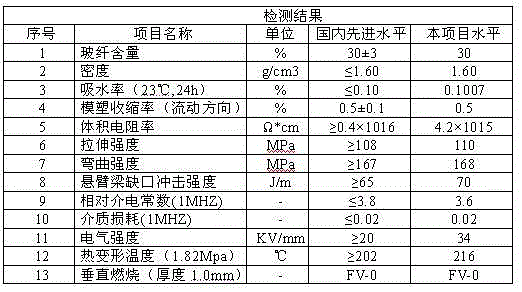

[0074] The trial-produced product of embodiment 1 will reach technical index and see table 2:

[0075] Table 2:

[0076]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com