Water source heat pump heat-supply device for oil field well mouth

A water source heat pump and heating device technology, applied in the direction of heating devices, geothermal power generation, and other non-combustion heat generation, can solve energy waste and other problems, achieve no environmental pollution, solve energy waste and operation safety hazards, and be easy Achieved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

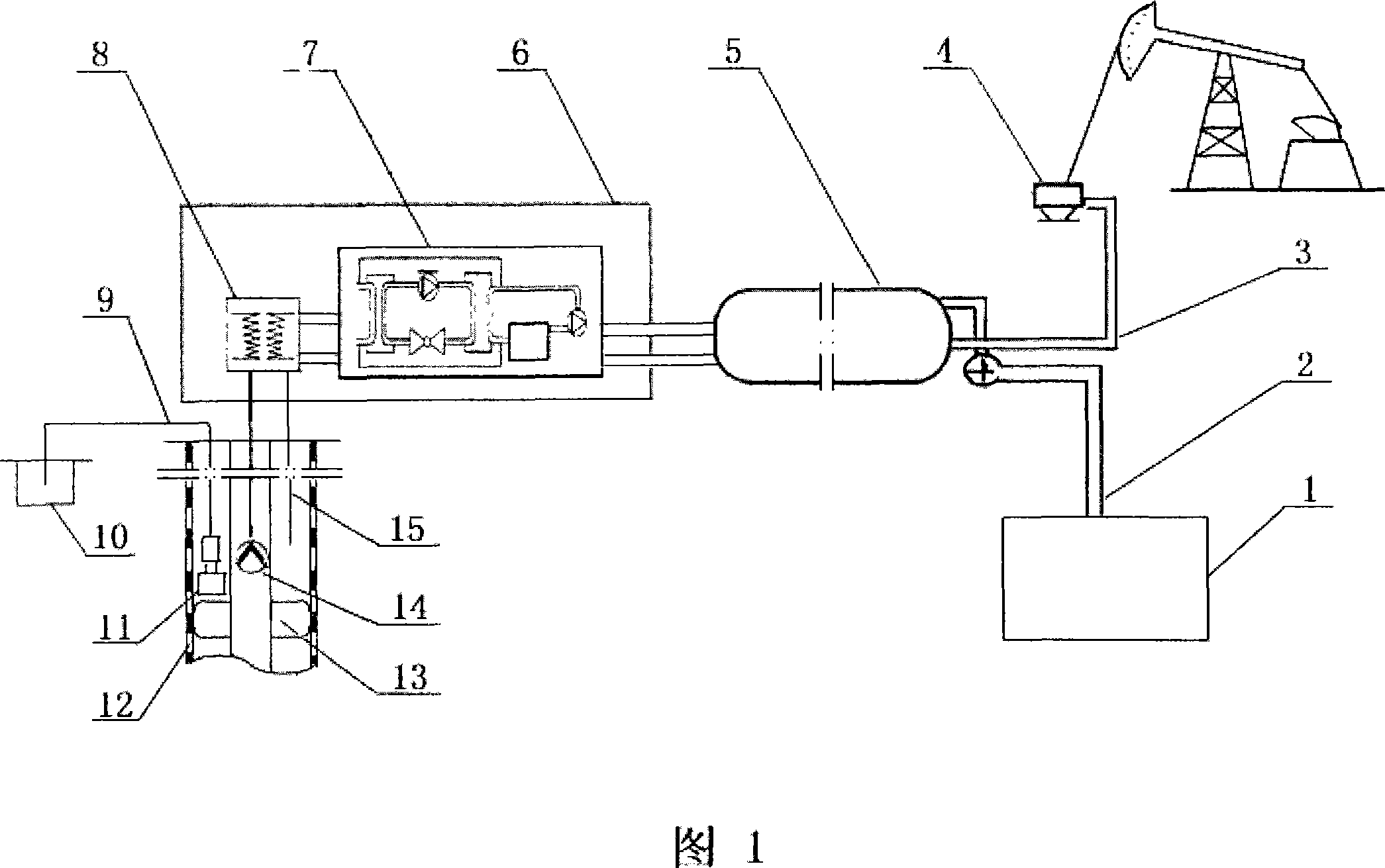

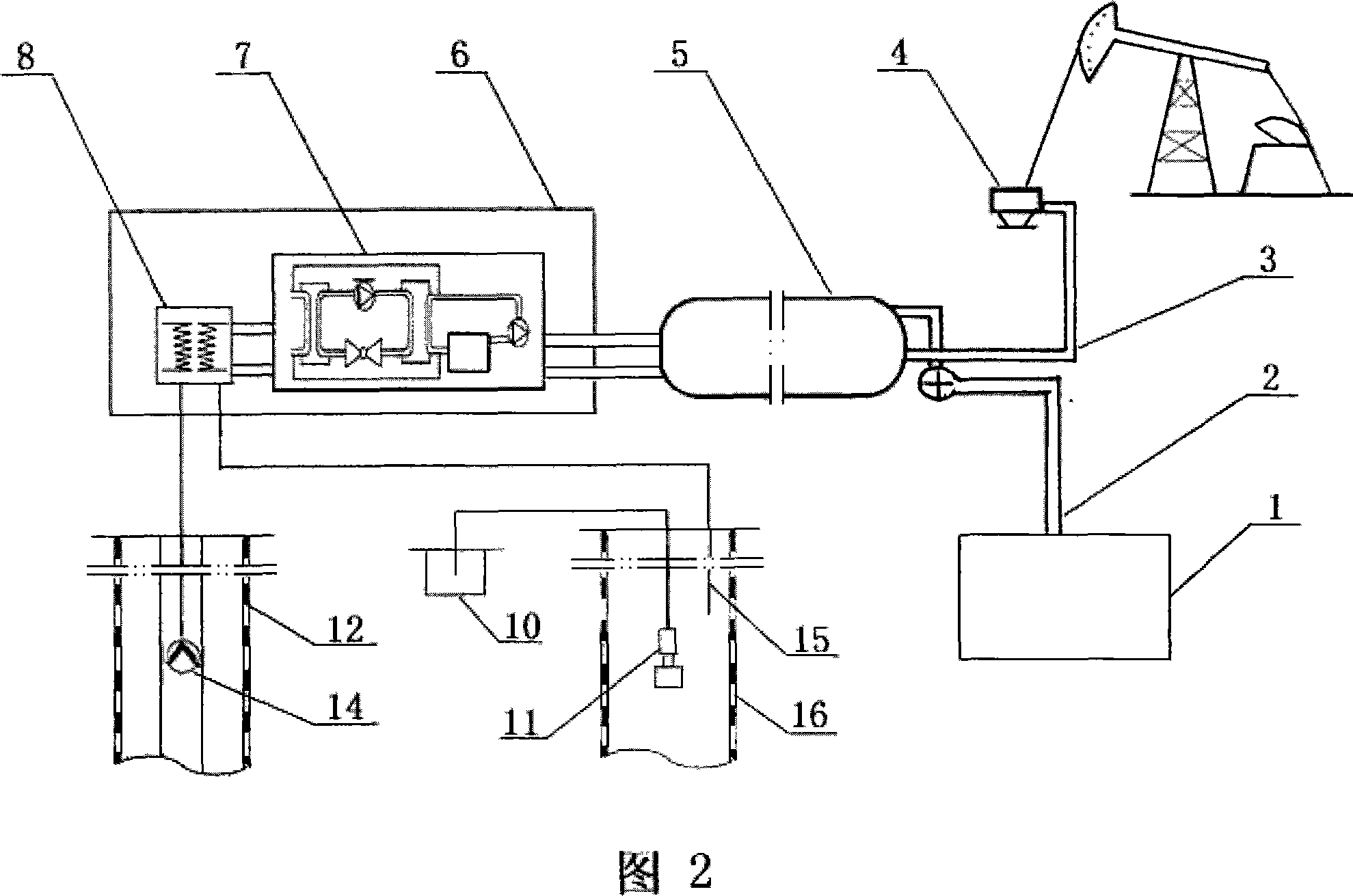

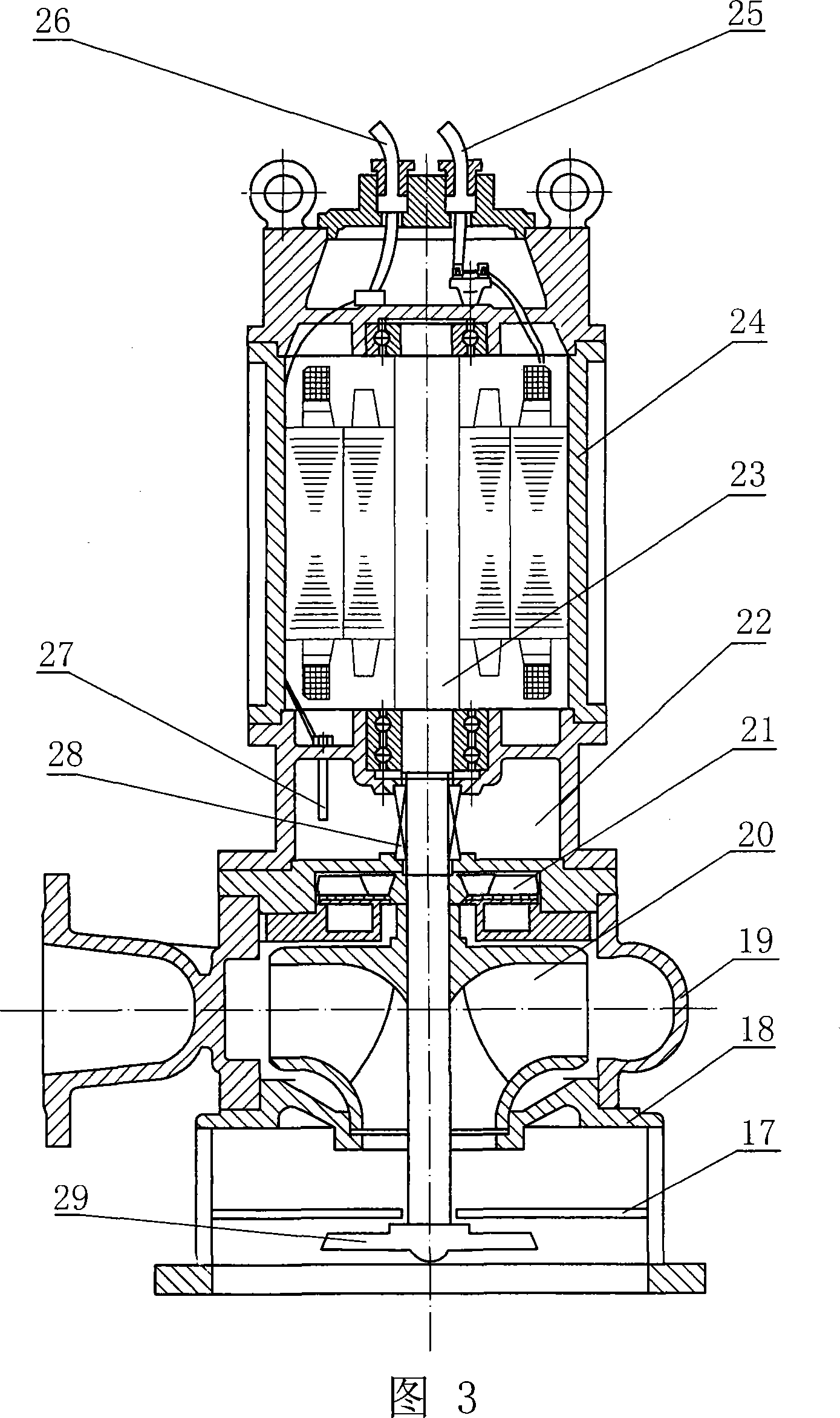

[0011] The specific structure of the present invention will be described in detail according to FIGS. 1 to 3 . The device adopts the mature heat pump heat collection technology and the heat collection method of the common heat exchanger to replace the traditional water jacket furnace heating device of the existing oil well. It can be designed according to the specifications and use needs of the heat collection well of the existing water source heat pump unit into type I and type II structures. Figure 1 shows a schematic diagram of the I-type structure. The automatic control powerful sewage pump is installed at the bottom of the recharge water layer in the well pipe where the heat collection well is a pumping well. What Fig. 2 shows is type II structure schematic diagram). It includes a heat pump unit 7 assembled in the machine room 6, a water source heat exchanger 8, a medium heater 5, a wellhead medium transmission pipe 3 connected to the wellhead 4 of the pumping unit, a he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com