Poly(ether-ether-ketone-ketone)containing triphenyl phosphine structure and synthetic method thereof

A technology of polyether ether ketone ketone and polyether ether ketone ketone resin, which is applied in the field of synthesis of new soluble high-temperature resistant polyetherether ketone ketone resin, can solve the problems of harsh synthesis conditions, high production cost, and poor product solubility, and achieve technological Ease of operation, excellent heat resistance, and high glass transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

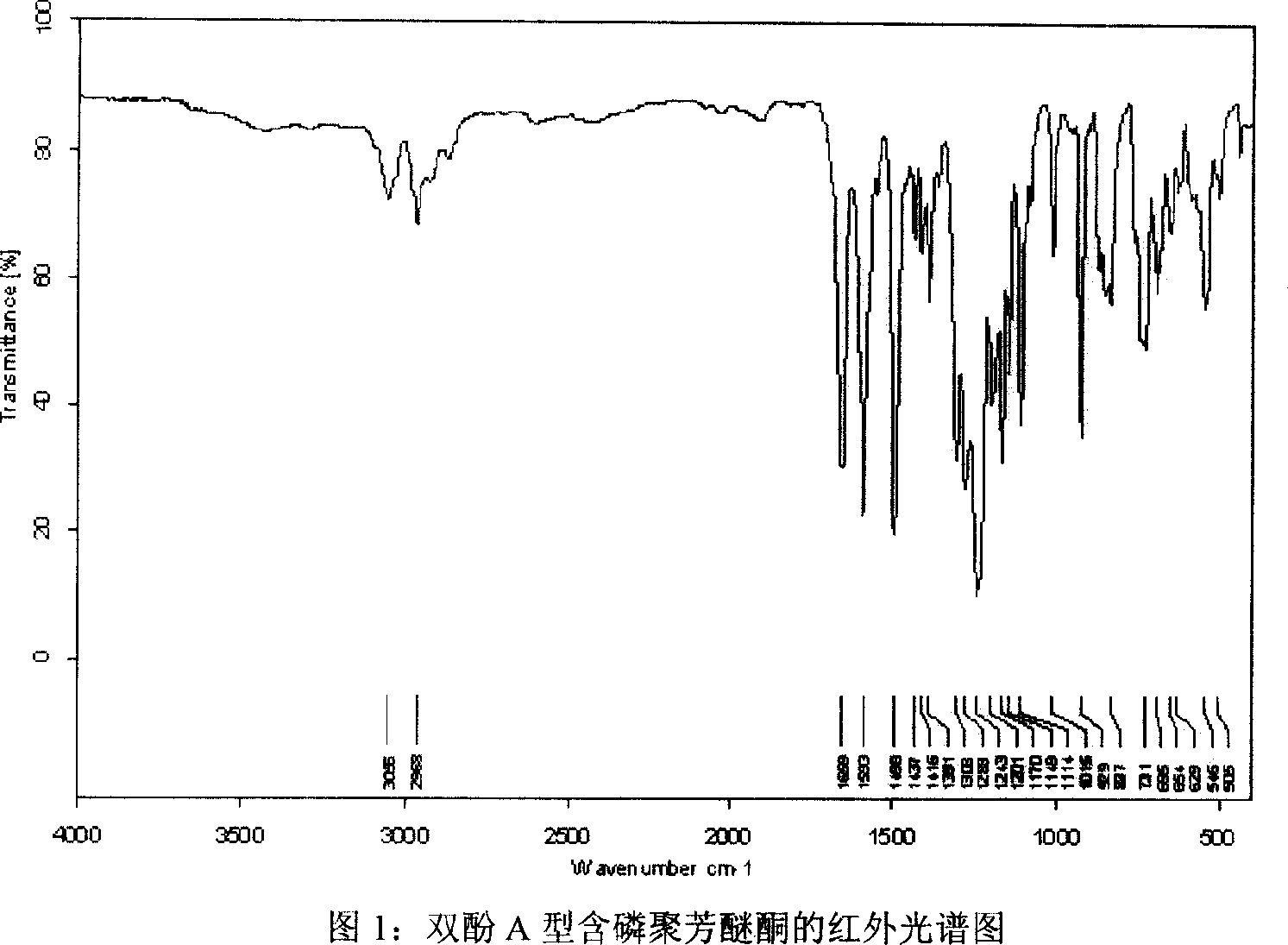

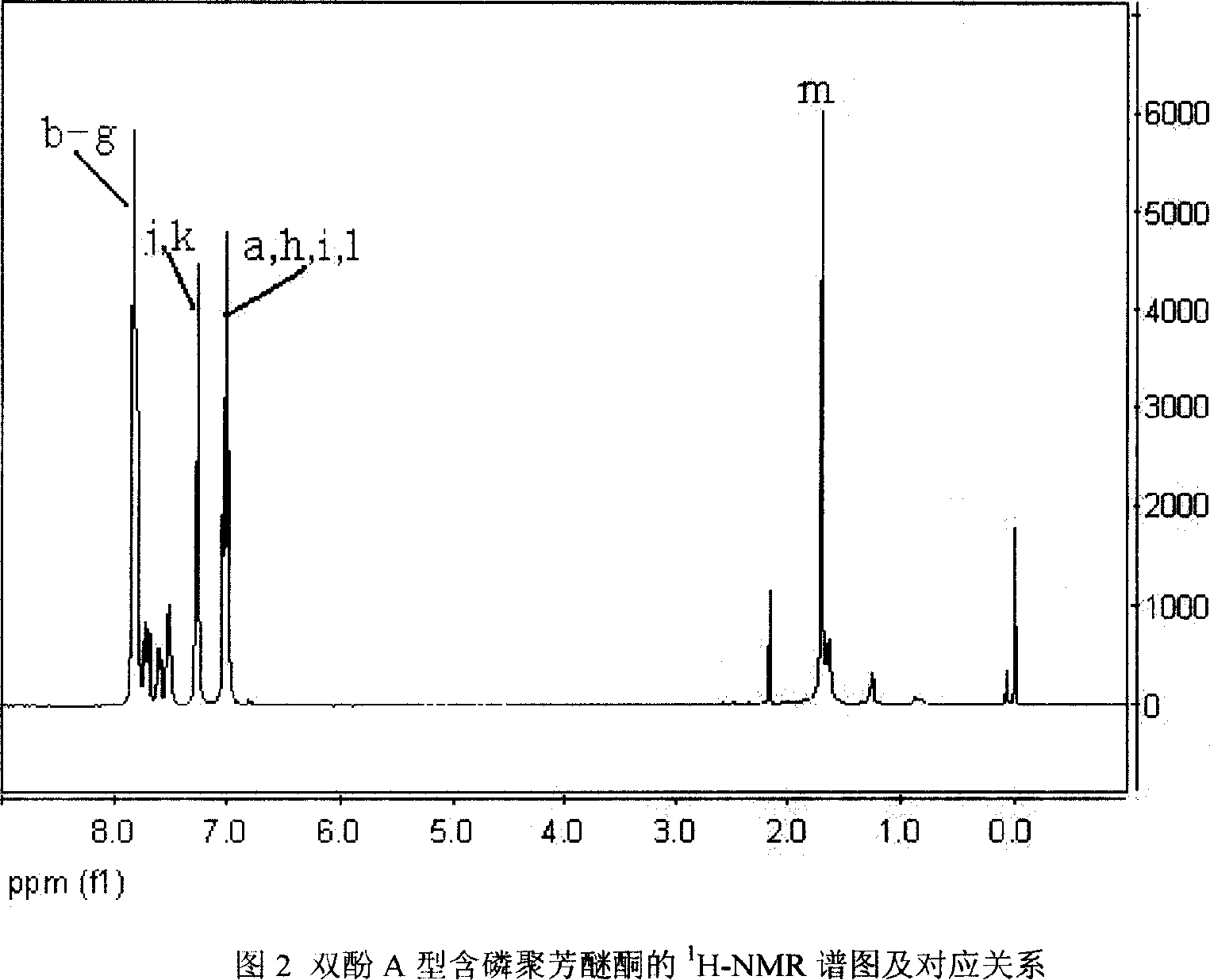

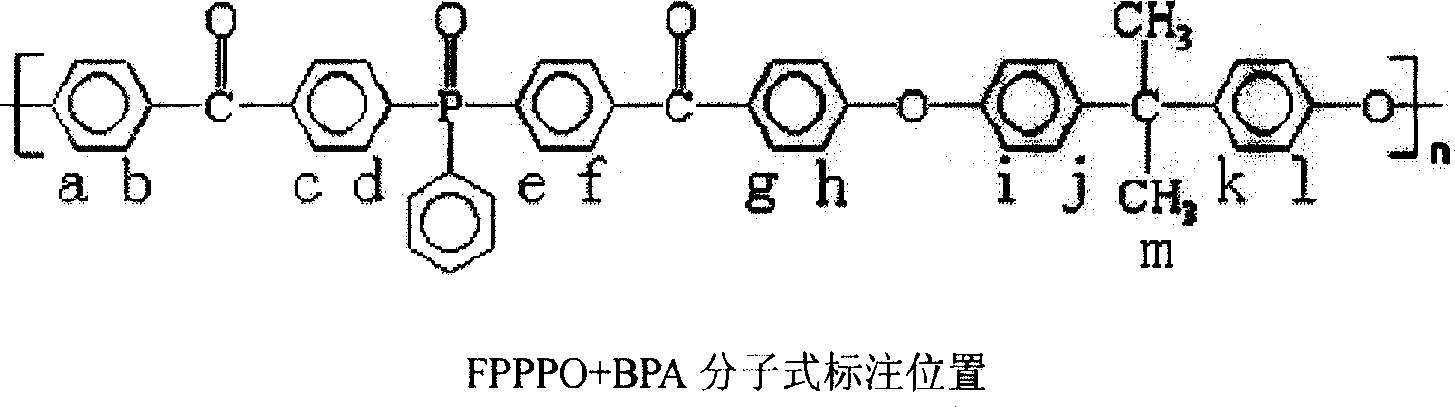

[0028] Embodiment 1: when magnetic stirring device, thermometer, water trap, condensation pipe and N are housed 2 FPPPO 3.132g (6mmol), BPA 1.368g (6mmol), K 2 CO 3 1.98g (14.4mmol), sulfolane 12ml, toluene 40ml, pass into N 2 , after reflux reaction at 120-125°C for 3 hours, evaporate the toluene and gradually increase the temperature, control the temperature at 190°C, stop the reaction after 1-15 hours of reaction, precipitate the product with absolute ethanol, filter, wash the product until neutral, 105 After drying at ℃ for 48 hours, a light yellow polymer was obtained with a yield of 94%. The product uses dichloromethane as a solvent, and the intrinsic viscosity measured by Ubbelohde viscometer at 25°C is η=0.73dL / g.

Embodiment 2

[0029] Embodiment 2: when magnetic stirring device, thermometer, water separator, condensation pipe and N are housed 2 Add FPPPO 3.132g (6mmol), BPS 1.50g (6mmol), K 2 CO 3 1.98g (14.4mmol), sulfolane 12ml, toluene 40ml, pass into N 2 , after reflux reaction at 120-125°C for 3 hours, distill out toluene and gradually increase the temperature, control the temperature at 180°C, stop the reaction after 5-20 hours of reaction, precipitate the product with absolute ethanol, filter, wash the product until neutral, 105 After drying at ℃ for 48 hours, a light yellow polymer was obtained with a yield of 90%. The product uses dichloromethane as a solvent, and the intrinsic viscosity measured by Ubbelohde viscometer at 25°C is η=0.55dL / g.

Embodiment 3

[0030] Embodiment 3: when magnetic stirring device, thermometer, water separator, condensation pipe and N are housed 2 Add FPPPO 3.132g (6mmol), HQ 0.66g (6mmol), K 2 CO 3 1.98g (14.4mmol), sulfolane 20ml, toluene 40ml, pass into N 2 , after reflux reaction at 120-125°C for 3 hours, distill out toluene and gradually increase the temperature, control the temperature at 180°C, stop the reaction after 5-20 hours of reaction, precipitate the product with absolute ethanol, filter, wash the product until neutral, 105 After drying at ℃ for 48 hours, a light yellow polymer was obtained with a yield of 95%. With dichloromethane as solvent, the intrinsic viscosity measured by Ubbelohde viscometer at 25°C is η=0.63dL / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com