Composite nano slurry-base fuel stabilizer, preparation and application

A technology of stabilizer and nano-slurry, which is applied in the field of composite nano-slurry-based fuel stabilizer and its preparation and application, and can solve the problems of failing to fundamentally improve the stability of water-coal/coke slurry, prone to degradation, and poor long-term stabilization effect, etc. problems, to achieve the effects of excellent timeliness, stable properties, and increased viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

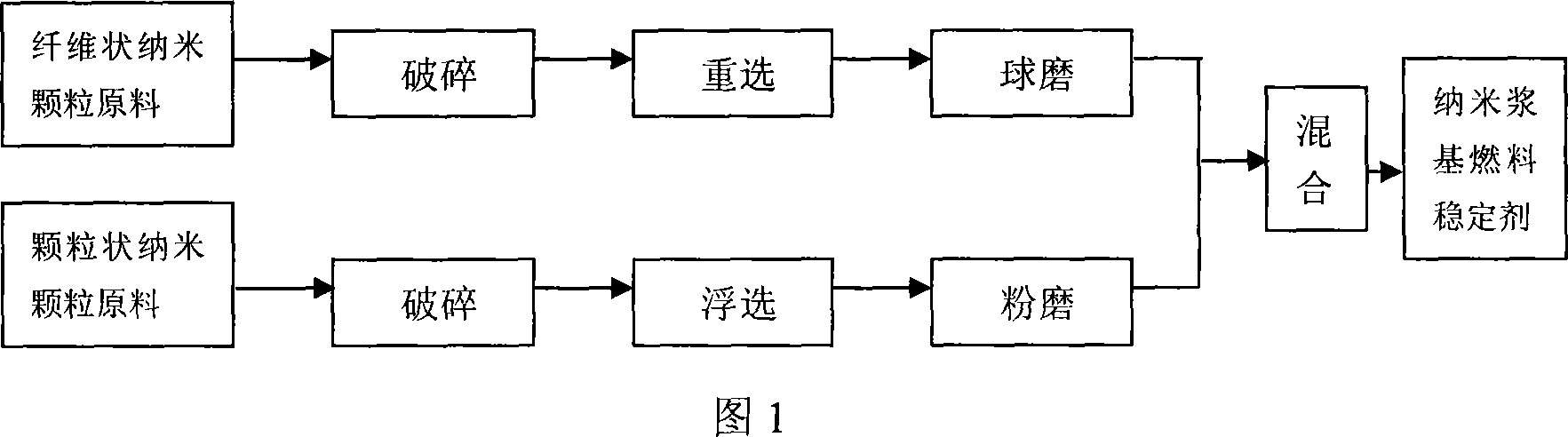

Method used

Image

Examples

Embodiment 1

[0016] Example 1: The stabilizing effect of composite nano-slurry-based fuel stabilizer on Xinglongzhuang coal-water slurry.

[0017] The composite nano slurry-based fuel stabilizer is prepared by combining fibrous attapulgite with an aspect ratio of 50 to 120 and spherical diatomite at a mass ratio of 50:50, and the particle size is 10-40 nanometers. Take this kind of stabilizer to prepare Xinglongzhuang coal-water slurry as an example: use XMB-Φ240×330 ball mill, add stabilizer, Xinglongzhuang coal, water and dispersant to the ball mill for grinding, and their addition amounts are respectively 2.00g, 1998g, 931g, 10.00g, after grinding for 60 minutes, high stability coal water slurry was obtained. The composite nano-slurry-based fuel stabilizer prepared by two kinds of inorganic nanoparticles according to the percentage ratio of 10:90, 30:70, 70:30, 90:10, with the same amount of stabilizer added, without changing the output of pulp, repeat the above test , adjust the addit...

Embodiment 2

[0019] Example 2: The stabilization effect of the composite nano-slurry-based fuel stabilizer on the petroleum coke water coke slurry of Qilu Petrochemical.

[0020] The composite nano-slurry-based fuel stabilizer is prepared by combining fibrous wollastonite with an aspect ratio of 30 to 100 and spherical diatomite at a mass ratio of 60:40, and the particle diameter is 60-100 nanometers. Take this kind of stabilizer to prepare Xinglongzhuang coal-water slurry as an example: use XMB-Φ240×330 ball mill, add stabilizer, Qilu Petrochemical petroleum coke, water and dispersant to the ball mill for grinding, and their addition amounts are respectively Be 8.00g, 1992g, 807g, 10.00g, after milling for 75 minutes, high stability water coke slurry was obtained. The composite nano-slurry-based fuel stabilizer prepared by two kinds of inorganic nanoparticles according to the percentage ratio of 20:80, 40:60, 50:50, 80:20, with the same amount of stabilizer added, without changing the pul...

Embodiment 3

[0022] Example 3: The stabilizing effect of the composite nano slurry-based fuel stabilizer on Datong kerosene coal slurry.

[0023] The fiber-shaped attapulgite and spherical kaolin with an aspect ratio of 120 to 150 are prepared in a mass ratio of 50:50 to prepare a composite nano-slurry-based fuel stabilizer, and the particle size is 40-60 nanometers. Take the preparation of Datong kerosene coal slurry with this kind of stabilizer as an example: use XMB-Φ240×330 ball mill, add stabilizer, Datong coal, coal tar and dispersant to the ball mill for grinding, and their addition amount is 2.80g , 1911g, 1017g, 8.50g, after milling for 100 minutes, a highly stable oil-coal slurry was obtained. The composite nano-slurry-based fuel stabilizer prepared by two kinds of inorganic nanoparticles according to the percentage ratio of 10:90, 30:70, 70:30, 90:10, with the same amount of stabilizer added, without changing the output of pulp, repeat the above test , adjust the addition rate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com