Gram-negative bacteria microcapsule and preparation method thereof

A technology of gram-negative bacteria and microcapsules, which is applied to bacteria, fixed on/in organic carriers, etc., can solve the problems of difficult storage and transportation, inconvenience, and decreased activity of liquid inoculants, and achieve good storage stability. Sex, the effect of strong growth and reproduction ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

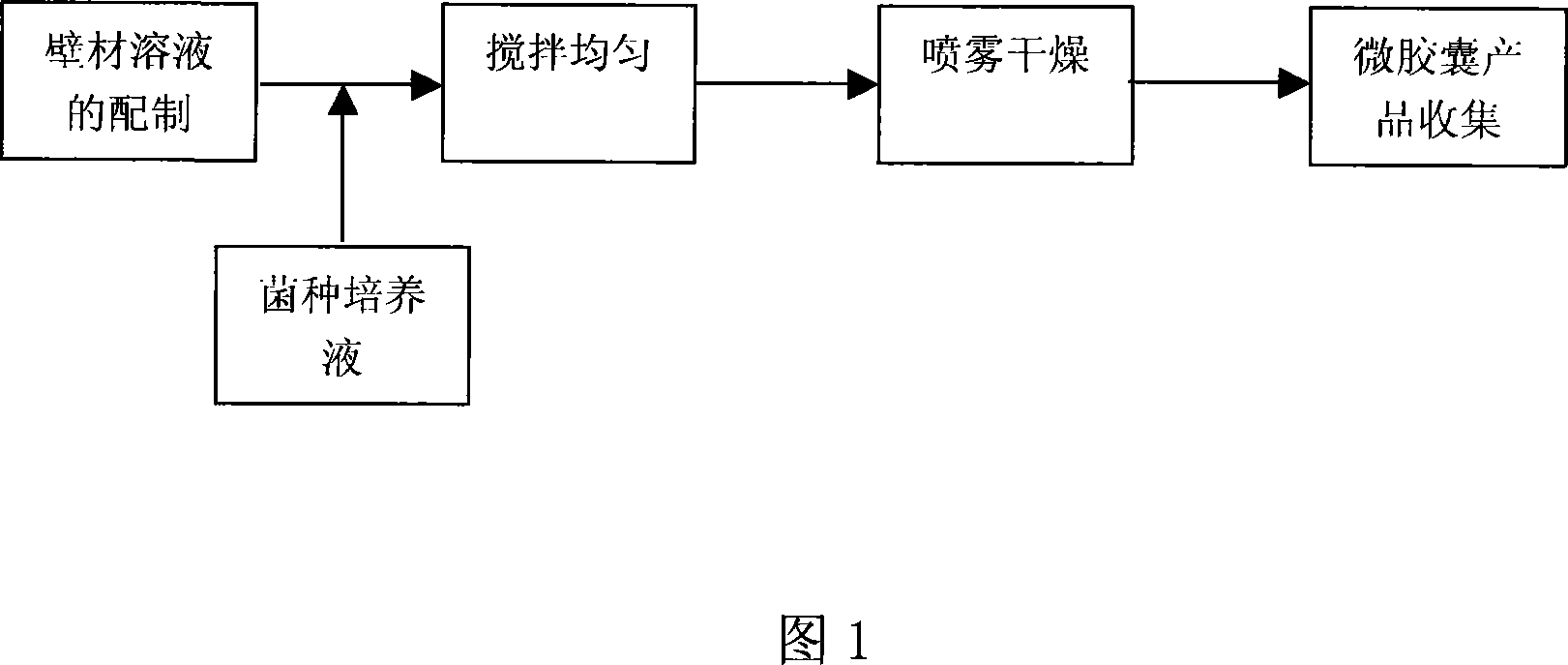

Method used

Image

Examples

Embodiment 1

[0009] Prepare a colloidal solution at 30°C according to the mass ratio of wall materials: gum arabic: maltodextrin: β-cyclodextrin: carboxymethyl cellulose 1:9:0.5:0.2, add 150ml of culture medium and stir evenly. Use a peristaltic pump to put the material into the atomizer for spray drying. The spray drying inlet air temperature is 140°C, the material feed flow rate is 6ml / min for spray drying, and the outlet air temperature is 50°C. The particle size range is 10μm-100μm. The microcapsule product has a live bacteria rate of 75.33%, and after eight months of storage, the order of live bacteria still reaches 10 9 pcs / g.

Embodiment 2

[0011] Prepare a gel solution at 30°C according to the mass ratio of wall materials: gum arabic: maltodextrin: β-cyclodextrin: carboxymethyl cellulose 1:9:0.5:0.2, add 150ml of culture medium and stir evenly . Use a peristaltic pump to put the material into the atomizer for spray drying. The spray drying air temperature is 160°C, and the material feed flow rate is 6ml / min for spray drying to obtain microcapsule products with a particle size range of 10 μm-100 μm. The rate of viable bacteria can reach 68.99%, and after eight months of storage, the order of viable bacteria still reaches 10 9 pcs / g.

Embodiment 3

[0013] Prepare a gel solution at 30°C according to the mass ratio of the wall material: gum arabic: maltodextrin:: β-cyclodextrin: carboxymethyl cellulose: 1:9:0.5:0.2, add 150ml of culture medium, Stir well. Use a peristaltic pump to put the material into the atomizer for spray drying. The spray drying inlet air temperature is 140°C, and the material feed flow rate is 15ml / min for spray drying to obtain microcapsule products with a particle size range of 10 μm-100 μm. The rate of viable bacteria can reach 71.69%, and after eight months of storage, the order of viable bacteria still reaches 10 9 pcs / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com