Sputtering target, a joined type sputtering target and a method of making such a joined type sputtering target

A production method and sputtering target technology, which are applied in the field of sputtering targets, can solve the problems of poor heat resistance, corrosion resistance, poor adhesion, and can not fully withstand electrical wiring, etc., and achieve excellent corrosion resistance and suppression of abnormal discharge. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The sputtering target of the present invention is a sputtering target containing Mo and Ti as main components, and can form a base film of a film made of a metal such as Au, Cu, or an alloy containing at least one of them.

[0016] In order to form a film having excellent adhesion to such a metal film or alloy film and also excellent corrosion resistance, the sputtering target of the present invention contains Ti more than 50 atomic % and not more than 60 atomic %. At this time, in order to improve and stabilize the properties of the metal thin film obtained by sputtering, it is desirable to contain as few impurities as possible, so the total of Mo and Ti excluding gas components is preferably a purity of 99.9% by mass or more. .

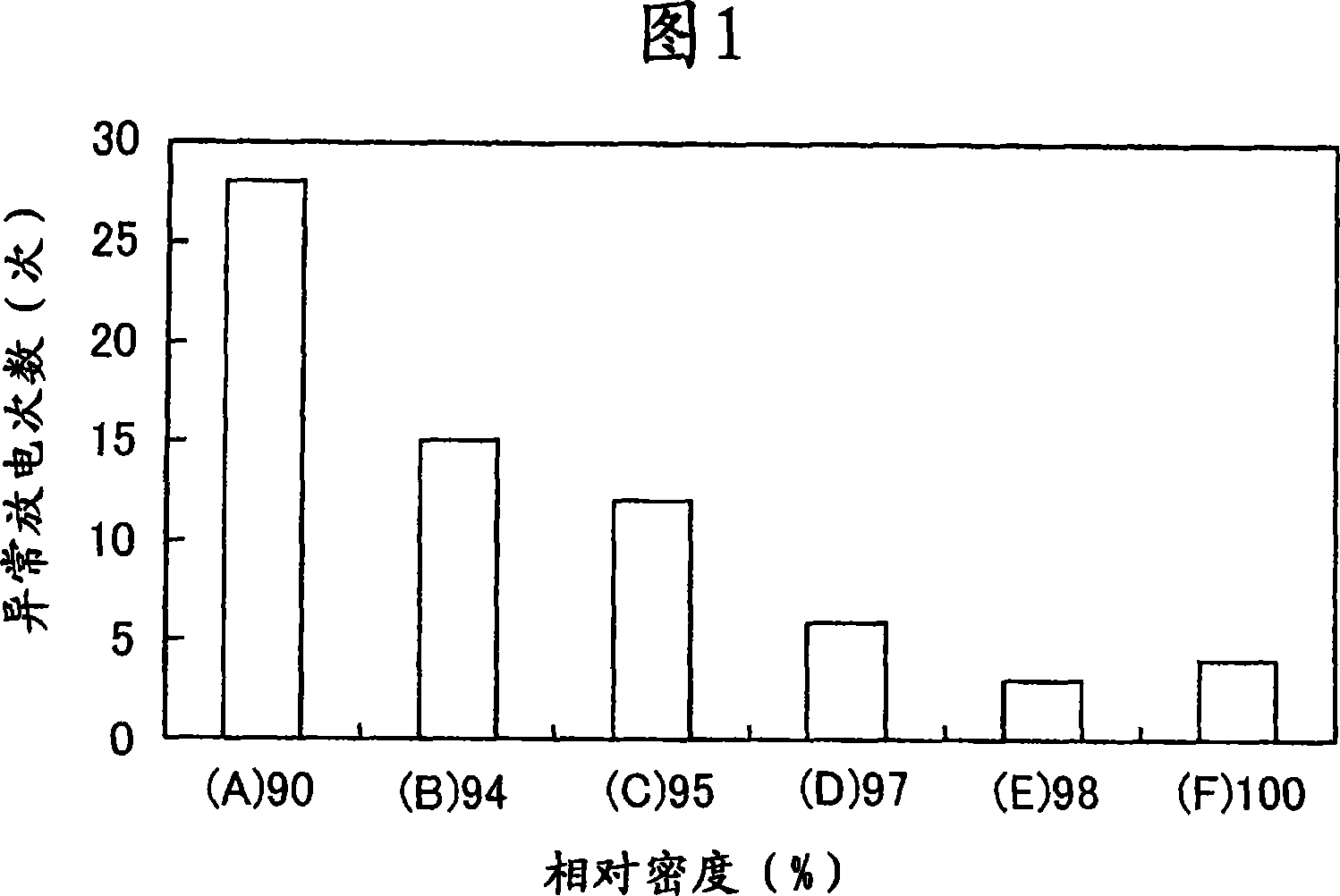

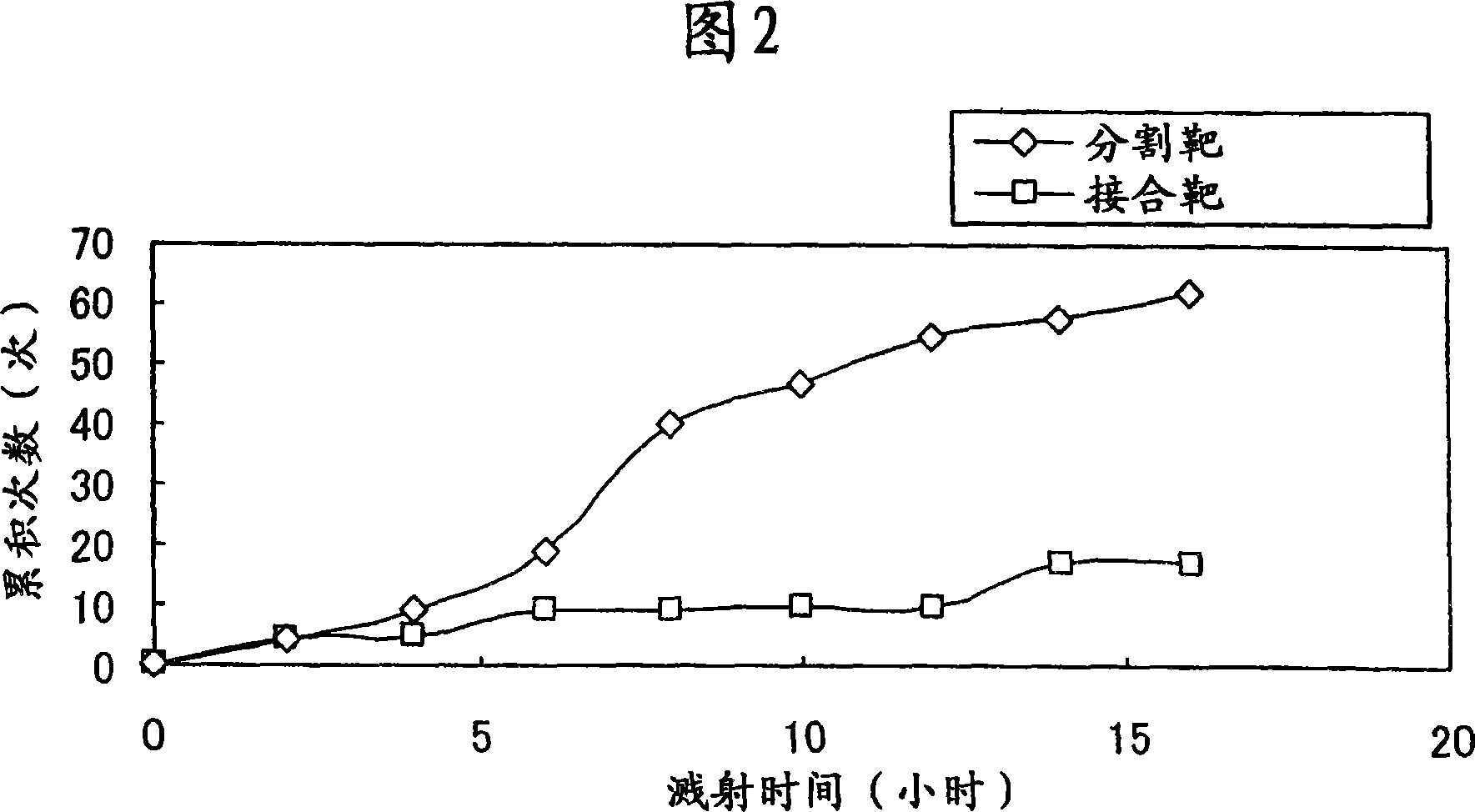

[0017] In addition, the oxygen concentration of the sputtering target is preferably 1000 to 3500 ppm. Generally, the lower the oxygen concentration, the better. However, when bonding two or more sputtering targets in order to produce a bonde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com