Mounting device for a sputter source

A sputtering source and sputtering technology, applied in sputtering plating, ion implantation plating, coating, etc., can solve problems such as damage and target heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

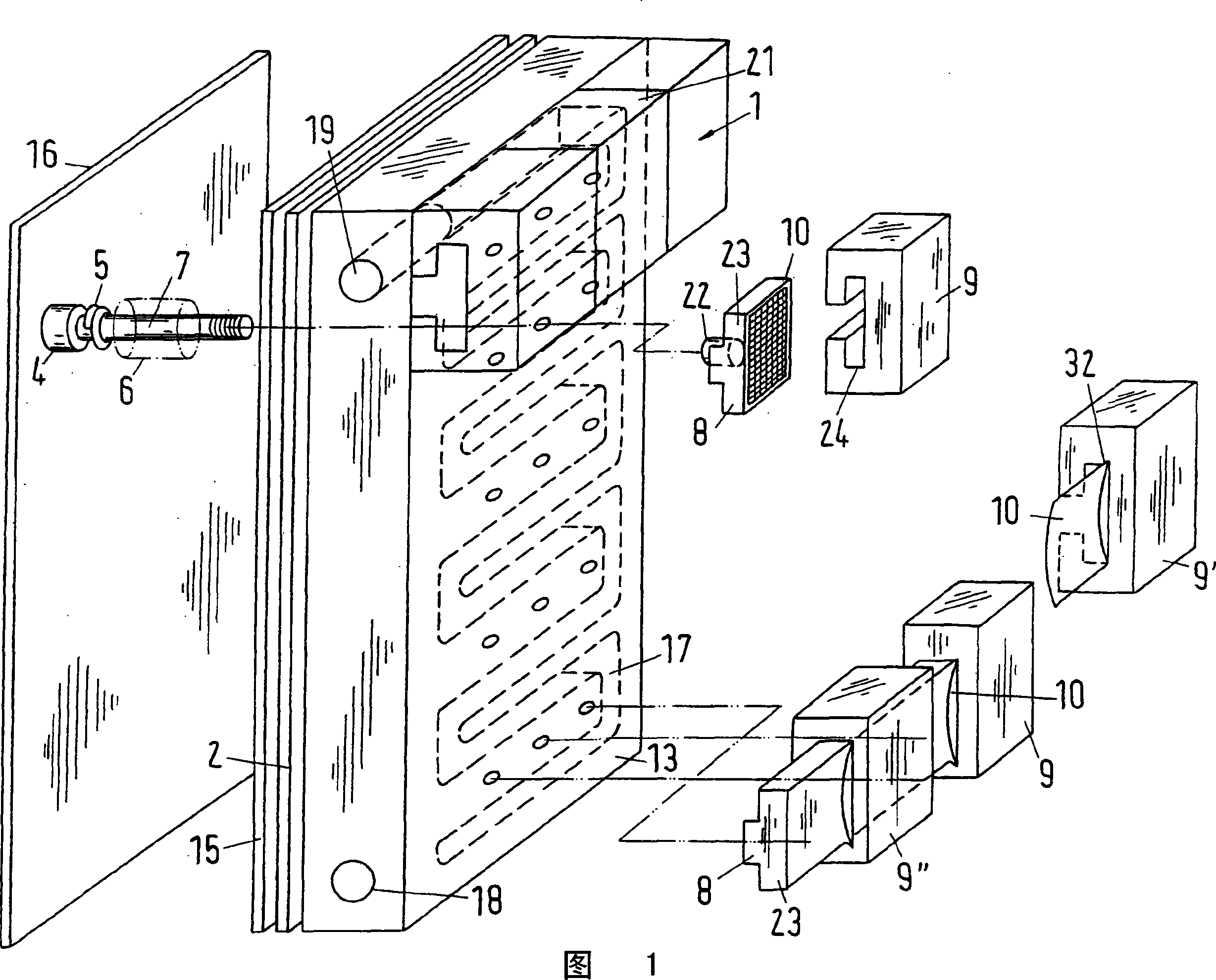

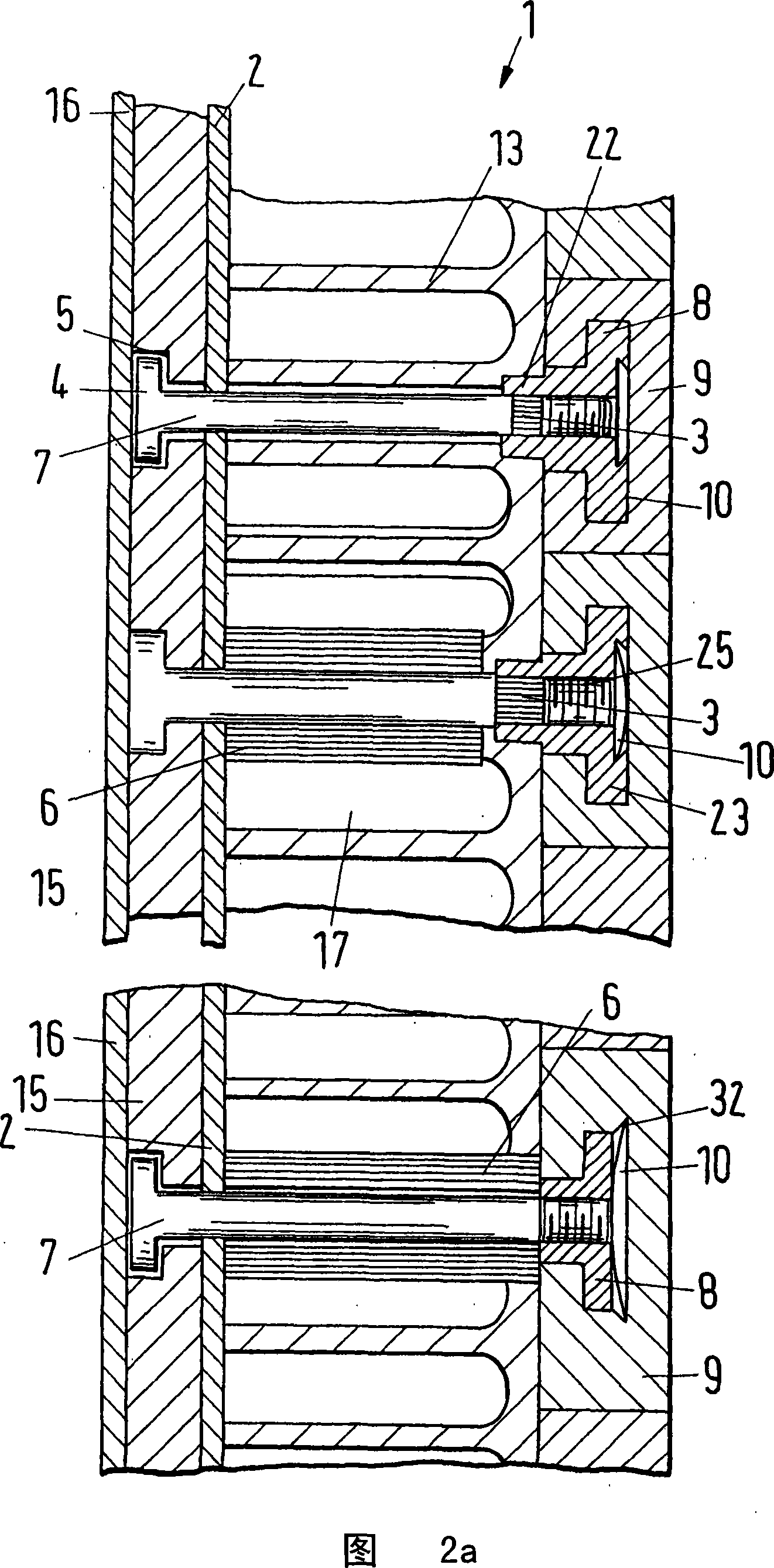

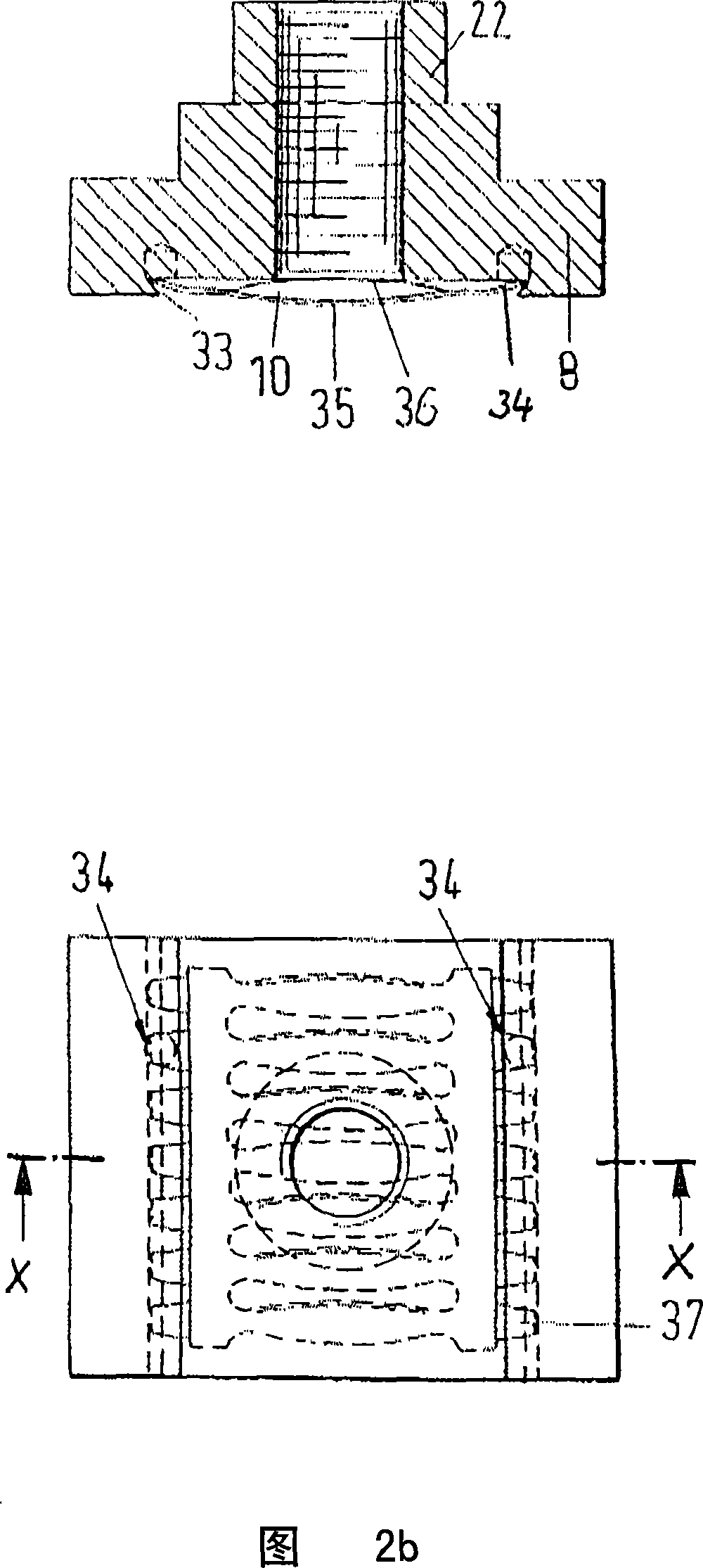

[0041] Figure 1 shows the arrangement of target segments 9 fastened to a target holder 1 in a coating source. Each target segment 9 is screwed to the outer wall 2 of the cooling body by means of a T-nut 8 . The T-nut comprises a cylindrical body 22 and an additional part 23 having a T-shaped cross-section. The cylinder 22 is received by a hole in the cooling body 13 . The T-shaped additional portion 23 protrudes beyond the inside surface of the cooling body. A contact layer 10 made of low-alloy copper or nickel, in particular CuBe, CuCoBe or NiBe, is attached to the T-nut and / or a galvanic coating is applied. At least one target segment 9 is plugged onto the T-nut 8 , and the T-nut and the target segment have an intermediate space in which the contact lamination 10 is arranged. In FIG. 1 the target segment 9 is plugged onto the T-shaped additional part 23 . A groove 24 is provided in the target section, said groove being widened into a T-shape, said groove being designed t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com