Constructional light wall partition slab material and producing method thereof

A kind of technology for construction and plate, which is applied in the direction of building materials, building structure, construction, etc. It can solve the problems of increased porosity of products, difficult secondary decoration of plates, rework of decoration projects, etc., to achieve hard surface, enhanced fireproof performance, The effect of random nailing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

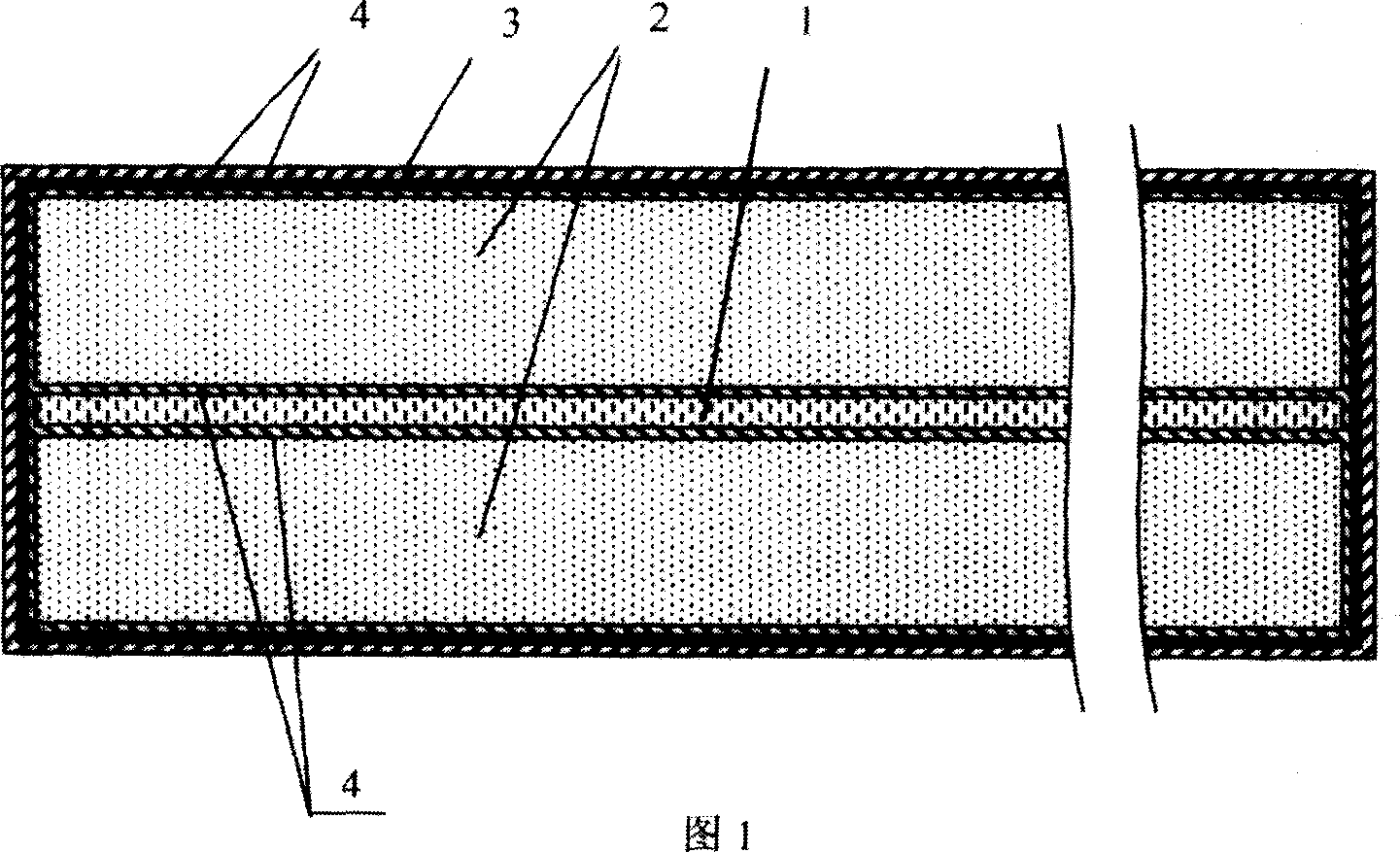

[0057] Embodiment 1, the structure is shown in Figure 1:

[0058] The product of this embodiment is a kind of lightweight partition wall plate for construction of 5.6cm thick single-layer glass fiber, and its specification is 2.02cm (length) * 1.02cm (width) * 5.6cm (thick).

[0059] Embodiment 1: The board has a central layer, the central layer is composed of a wooden thin board 1 in the middle and two foamed plastic boards 2 up and down, and there is a bond between the wooden thin board and the two foamed plastic boards The material layer 4 is covered with a glass fiber cloth layer 3 around the center layer, and there is a bonding material layer 4 between the center layer and the glass fiber cloth layer and on the surface of the glass fiber cloth. The bonding material layer on the surface of the glass fiber cloth is the surface layer of the partition wall board.

[0060] The raw materials for the preparation of the bonding material layer include: caustic dolomite (CaO MgO),...

Embodiment 2

[0071] According to the following steps, a kind of lightweight partition wall panel for construction as described in the above embodiment is manufactured:

[0072] Firstly, the preparation raw materials of the bonding material layer are stirred into gelatinous paddle material according to the proportion described in the first embodiment, and then the construction is carried out according to the following steps on the production equipment:

[0073] (1) Put a carrier frame on the production equipment platform, and put a smooth flat plate of 2.02m×1.02m on the carrier frame;

[0074] (2) On the smooth flat plate, evenly coat a layer of bonding slurry material according to the size range of the lightweight partition wall plate;

[0075] (3) Lay glass fiber cloth with more edge wrapping size on the bonding slurry material layer;

[0076] (4) Coating a layer of bonding slurry material on the glass fiber cloth;

[0077] (5) The foamed plastic plate (2.5cm or 6cm) that the bottom surf...

Embodiment 3

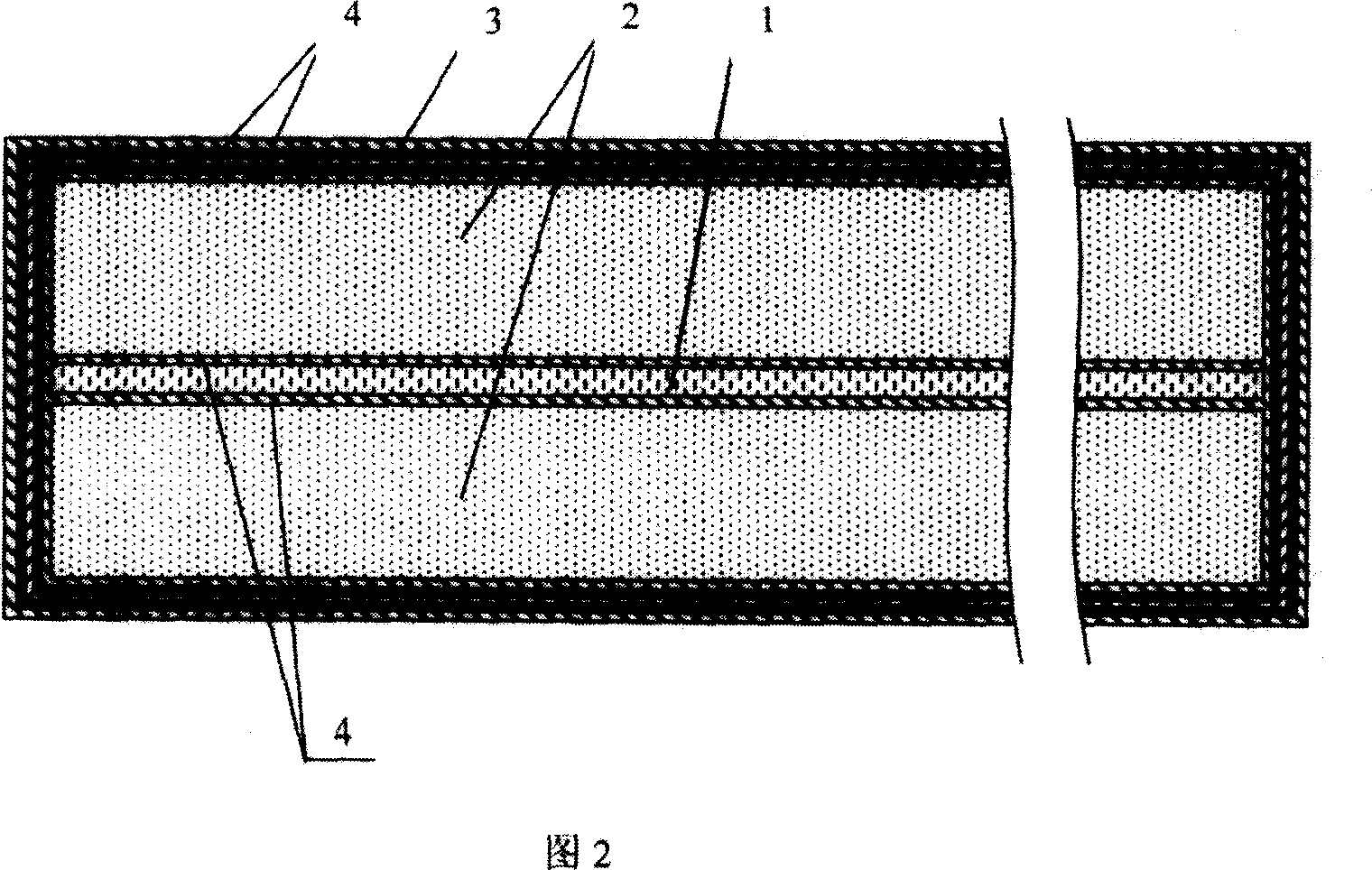

[0092] Embodiment 3, the structure is shown in Figure 2:

[0093] The difference between this embodiment and Embodiment 1 is that: the center layer is covered with more than two layers of glass fiber cloth 3, and there is a bonding material layer between each glass fiber cloth, and the bonding on the surface of the outer layer of glass fiber cloth The material layer is the surface layer of the partition wall board.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com