Micro-water and mixed gas ultrasonic on-line detecting method and device in transformer oil

A technology of transformer oil and mixed gas, which is applied in the direction of measuring devices, material analysis using sound waves/ultrasonic waves/infrasonic waves, instruments, etc., which can solve the high requirements of ambient temperature, high temperature sensitivity requirements, moisture content deviation, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

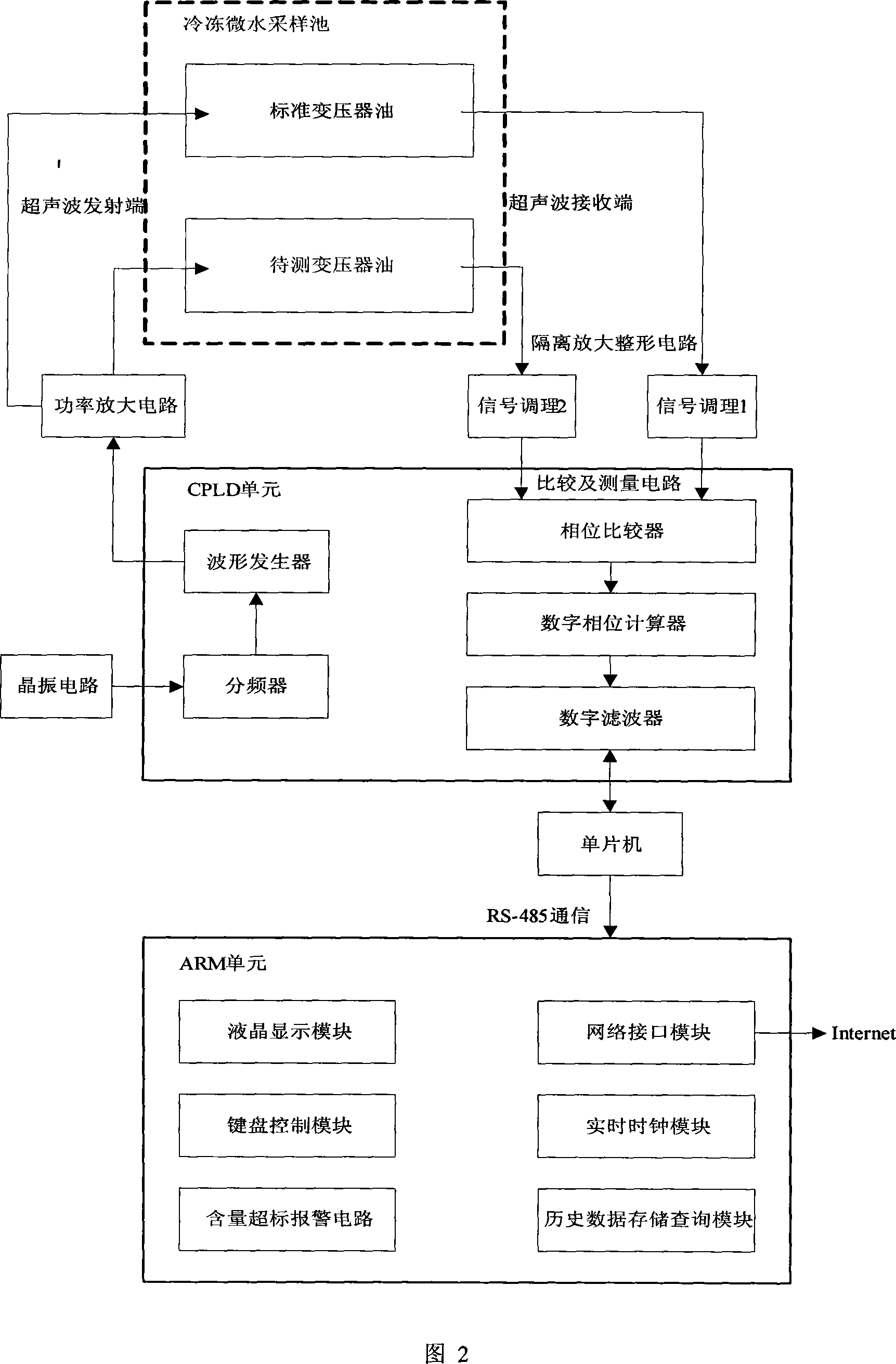

[0060] The transducer at the ultrasonic transmitting end is composed of an ultrasonic transmitting transducer; the ultrasonic receiving transducer at the ultrasonic receiving end is composed.

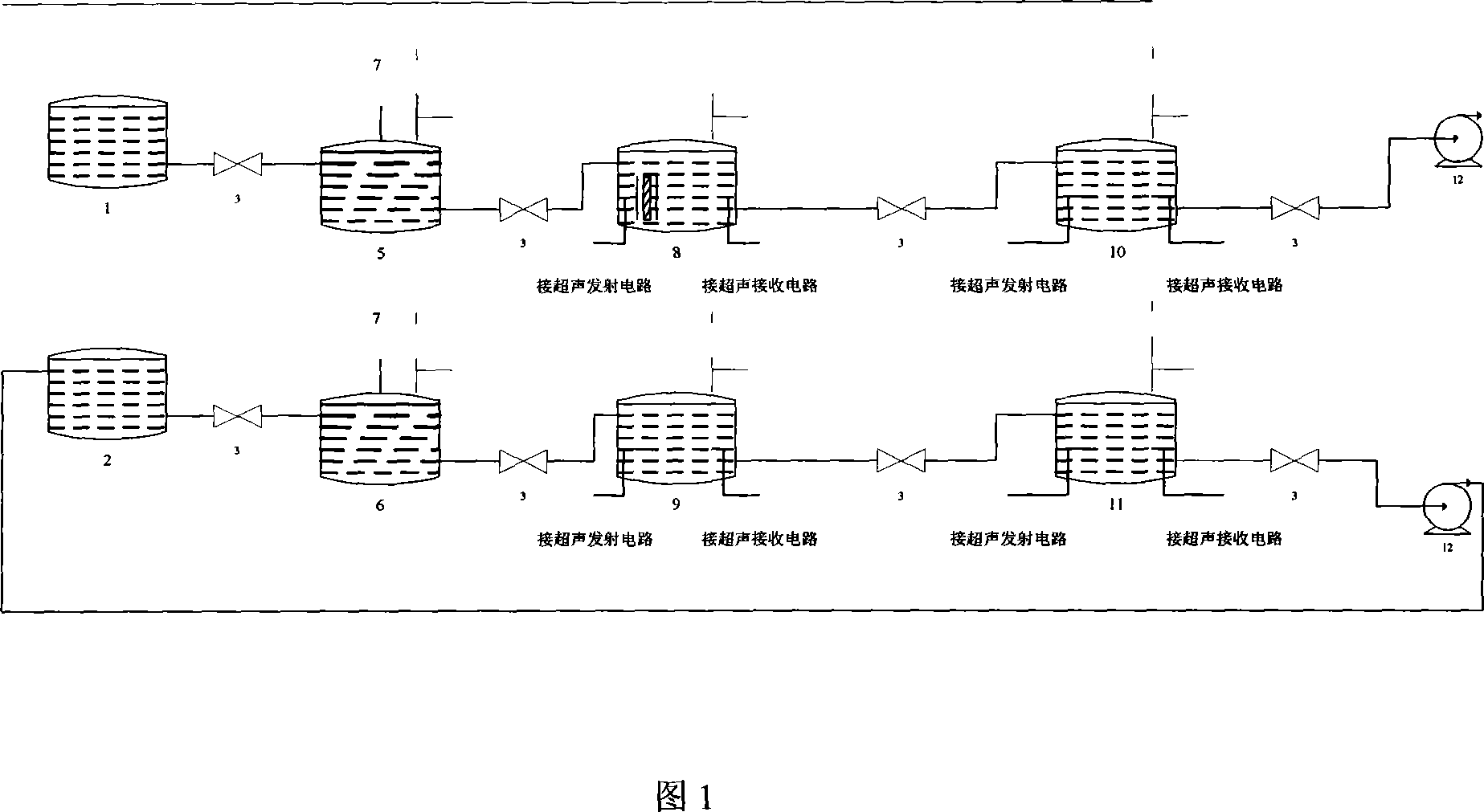

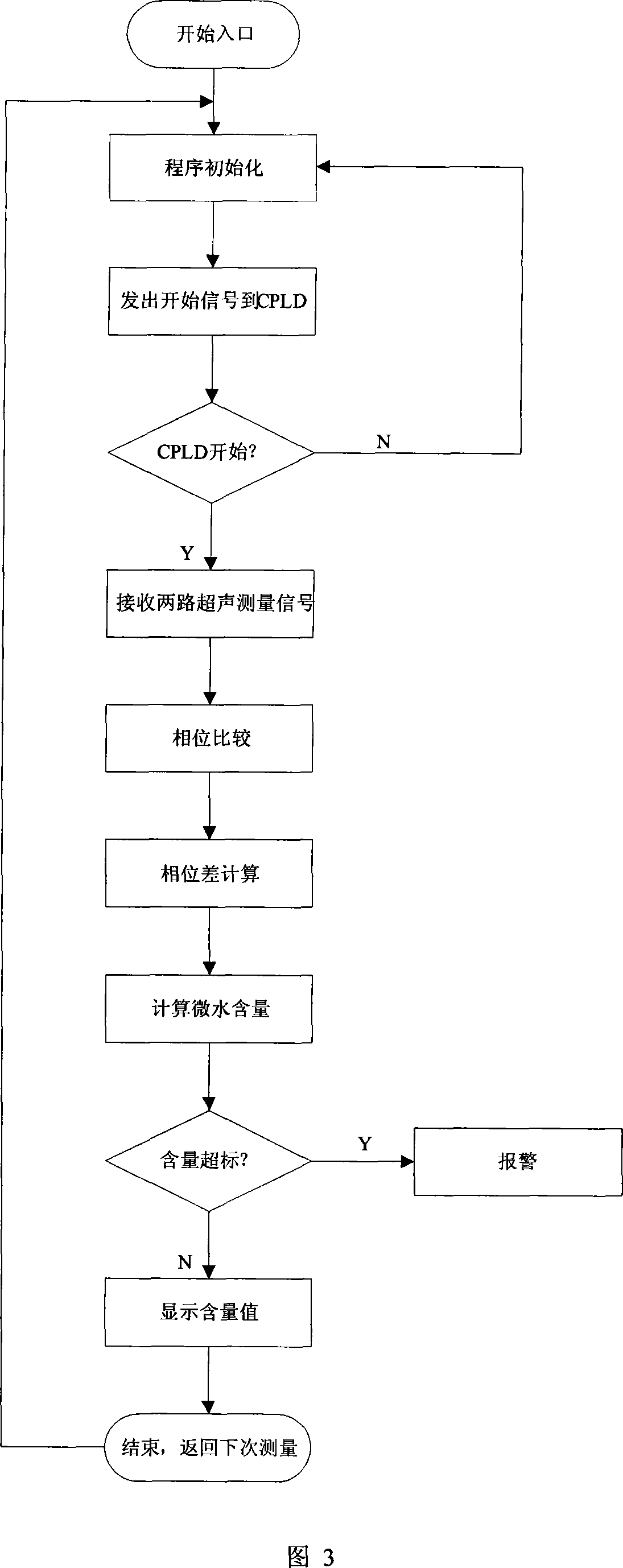

[0061] The phacoemulsification device is an emulsification pool with n ultrasonic power sources. The sampling of the micro-water freezing pool and the mixed gas pool are respectively composed of a pair of ultrasonic transmitting and receiving transducers. One is for the standard transformer oil freezing pool, and the other is for the transformer oil freezing pool to be tested. The emulsified standard transformer oil and the transformer oil to be tested flow into their respective freezing pools through the circulation pipe for freezing operation. The heating pool is also mainly composed of two pairs of ultrasonic transducers, one is used for the standard transformer oil heating pool, and the other is used for the transformer oil heating pool to be tested. The standard transformer oil a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com