Column-hole type rectification tower

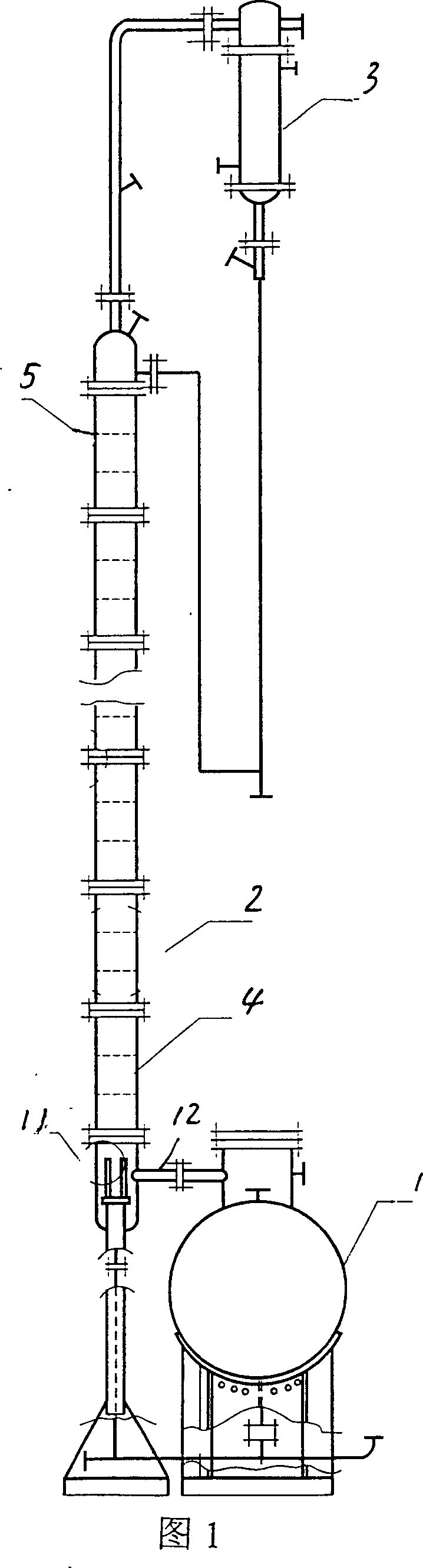

A rectification tower and column hole technology, which is applied in the field of devices for purifying arsenic trichloride, can solve the problems of lower product qualification rate, broken quartz kettle, contamination, etc., and achieve improved operation safety, improved performance, and reduced maintenance the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

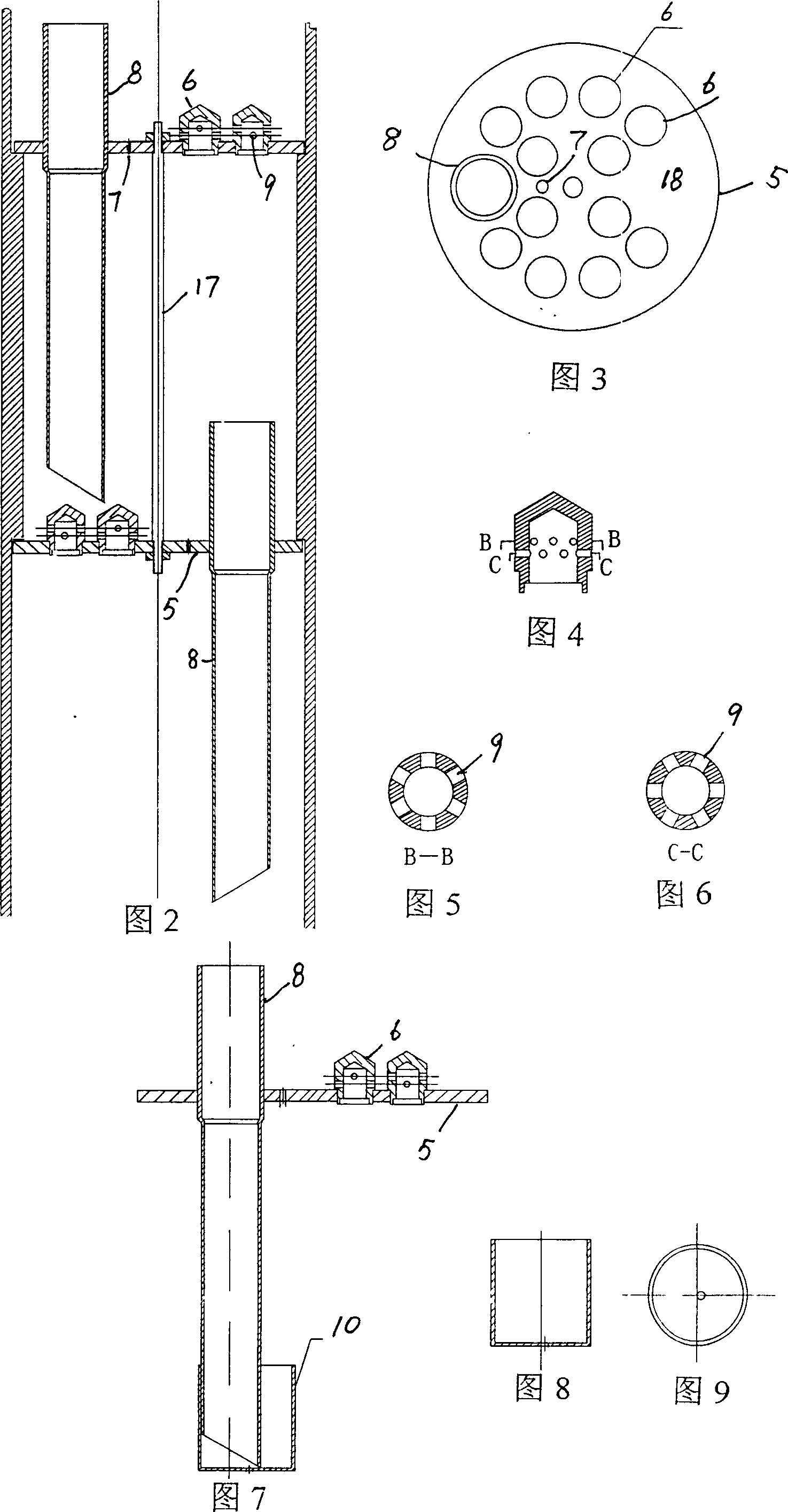

Embodiment Construction

[0041] The uniform corrosion, pore corrosion and crevice corrosion of GH182 are much lower than other steels, that is, GH182 has strong acid resistance and can be used in acidic environment. Therefore, the present invention selects the domestic GH182 (produced by Fushun Iron and Steel Co., Ltd., Liaoning) for use in the column hole type rectifying tower.

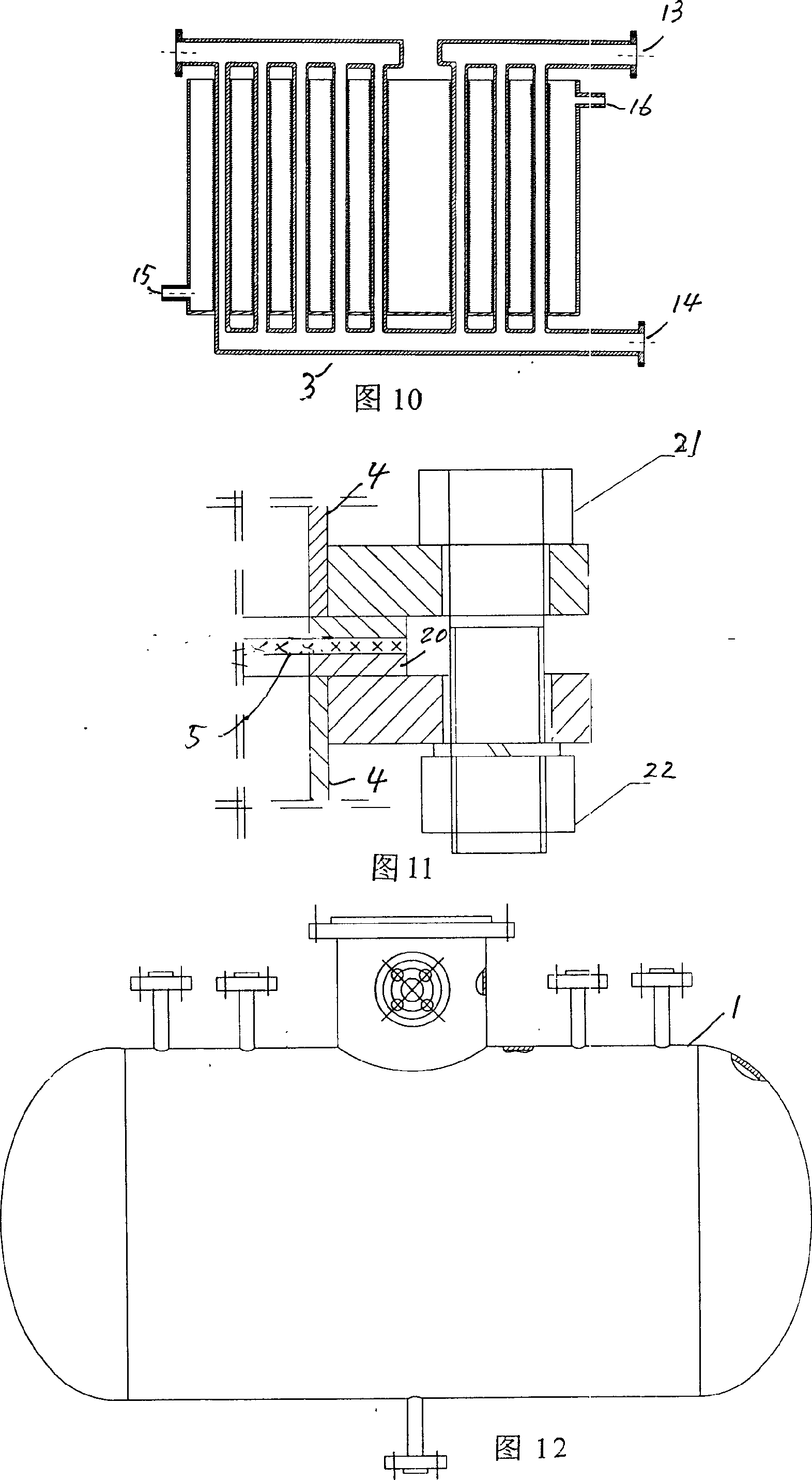

[0042] Tower type selection

[0043] For a specific column, there is a suitable gas range, as shown in Figure 13, the relationship between the efficiency of several types of trays and the load factor.

[0044] According to the characteristics of arsenic trichloride and the characteristics of the production process, combined with the comparison of the relationship curves of several tray efficiencies and load factors, such as curve 4 is a through-flow sieve tray column with large processing capacity and high tray efficiency (close to 90 %), but the operating flexibility is small and difficult to control. Curve 1 is an overfl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com