N-isopropyl acrylamide thermosensitive aquagel and its microwave radiation preparing method

A technology of isopropylacrylamide and heat-sensitive hydrogel, which is applied in the field of preparation of intelligent polymer materials, can solve the problems of hydrogel pollution, reduced sensitivity, difficulty in dissolution of pore-forming agent, etc., and can improve the saturated swelling rate. And, the effect of improving specific surface area and capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

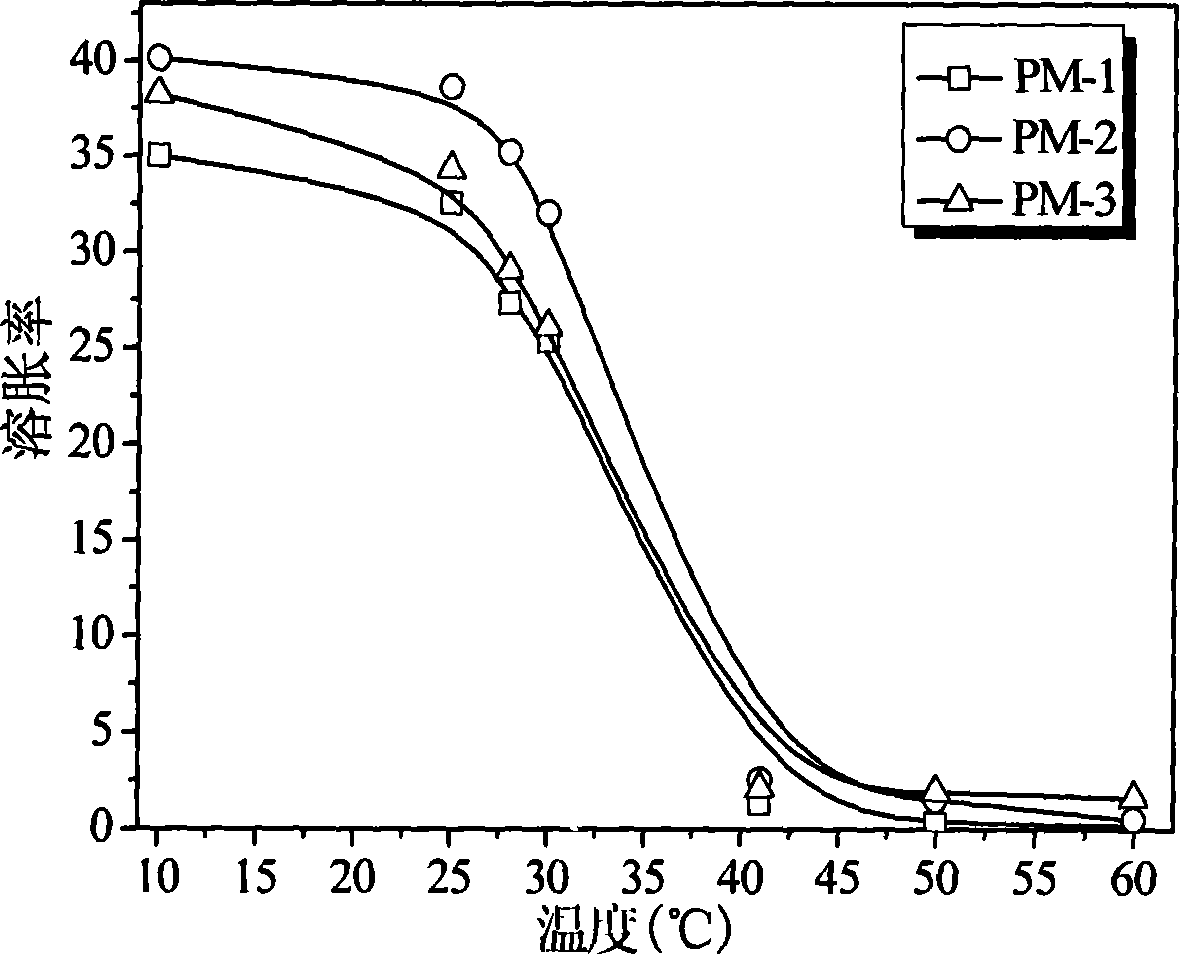

Embodiment 1

[0028] 10mL of acetone, 2.0000g of NIPAAm, 0.050g of cross-linking agent (BIS-A) and 0.1mmol of initiator (AIBN) were added to the round-bottomed flask, and nitrogen gas was introduced to exhaust oxygen for 70 minutes (the input volume was 5.6L); The solution was transferred to a cylindrical micro-reactor, placed in a microwave workstation, and a microwave with a frequency of 2450 MHz and a power of 30 W was applied and the reaction temperature was controlled at 70° C. (ie, the set temperature). In the process of microwave action, the reaction system is in the reaction stage of continuous heating under the action of 30W power, and reaches the set temperature of 70℃ in 60s. Then the microwave enters the constant temperature reaction stage, and the temperature of the reaction solution is kept at 70°C. This process lasts for 60 minutes and then stops. At this time, the reaction ends. The subsequent processing is the same as the ordinary water bath method, and the synthesized hydro...

Embodiment 2

[0030] Add 12mL of acetone, 2.0000g of NIPAAm, 0.023g of crosslinking agent (BIS-A) and 0.1mmol of initiator (AIBN) to the round-bottomed flask in turn, bubbling in nitrogen gas for 70 min (inlet volume is 5.6L); The solution was transferred to a cylindrical micro-reactor, placed in a microwave workstation, and a microwave with a frequency of 2450 MHz and a power of 100 W was applied and the reaction temperature was controlled at 80° C. (ie, the set temperature). In the process of microwave action, the reaction system is in the reaction stage of continuous heating under the action of 100W power, and reaches the set temperature of 80°C in 53s. Then the microwave enters the constant temperature reaction stage, and the temperature of the reaction solution is kept at 80° C. This process lasts for 30 minutes and then stops, at which time the reaction ends. The subsequent processing work is the same as the ordinary water bath method, and the synthesized hydrogel is labeled as PM-2.

Embodiment 3

[0032] 14mL of acetone, 2.0000g of NIPAAm, 0.050g of crosslinking agent (BIS-A) and 0.1mmol of initiator (AIBN) were added to the round-bottomed flask, and nitrogen was blown into the flask for 70 minutes (the flow rate was 5.6L); The solution was transferred to a cylindrical micro-reactor, placed in a microwave workstation, and a microwave with a frequency of 2450 MHz and a power of 200 W was applied and the reaction temperature was controlled at 90° C. (ie, the set temperature). In the process of microwave action, the reaction system is in the reaction stage of continuous heating under the action of 200W power, and reaches the set temperature of 90℃ in 45s. Then the microwave enters the constant temperature reaction stage, and the temperature of the reaction solution is kept at 90° C. This process lasts for 60 minutes and then stops, at which time the reaction ends. The subsequent processing is the same as the ordinary water bath method, and the synthesized hydrogel is labele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com