Long-chain polyether type silane coupler of glycidol-ether-radical end-capping

A glycidyl ether-based, silane coupling agent technology, applied in the direction of silicon organic compounds, can solve problems such as agglomeration and short molecular chains of coupling agents, and achieve the effect of promoting dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

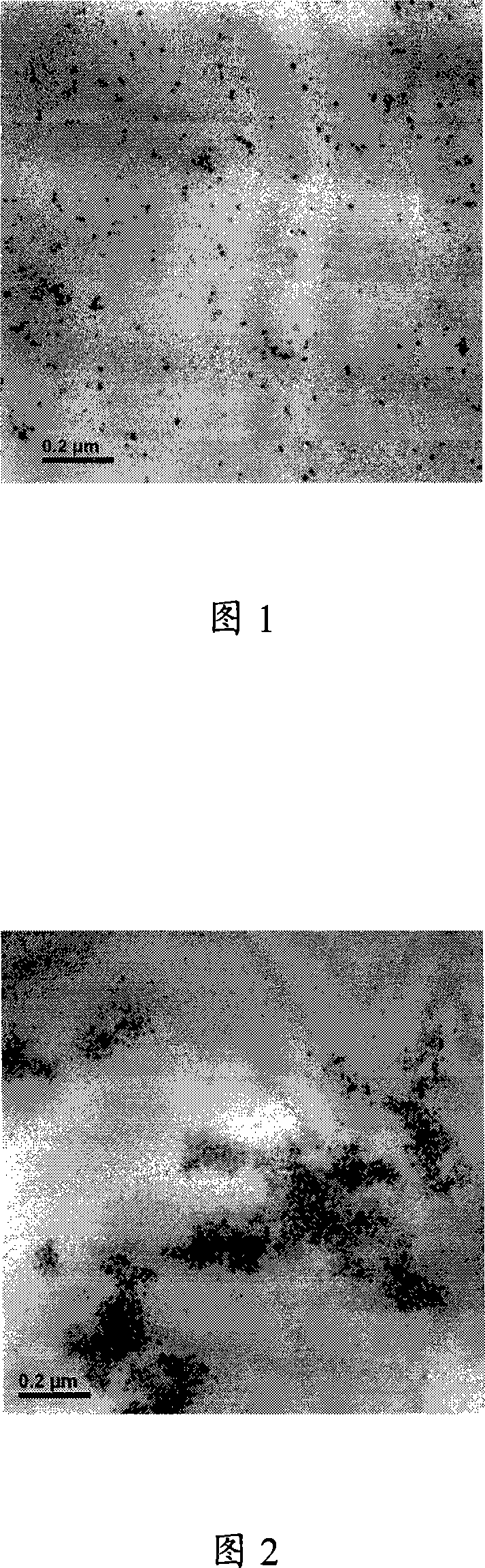

Image

Examples

Embodiment 1

[0021] With thermometer, condenser, stirrer, N 2 Add 40g of allyl polyether (n=2, m=5) (molecular weight: 436) into a 250mL dry four-neck flask with an inlet, and vacuum degas at 120°C for 30min. After the temperature drops to 70°C, add 0.24g Tin chloride (catalyst dosage 6‰), use a micro-injector to drop 13g of epichlorohydrin, the dropping time is controlled within 1 to 2 hours, and the temperature is controlled not to rise significantly. After the dropping, continue to react for 1.5 hours, reduce The unreacted epichlorohydrin was removed to obtain 49.2 g of the product chlorohydrin ether intermediate, with a conversion rate of 94.35%.

[0022] Dissolve the obtained 49.2g chlorohydrin ether intermediate in 40mL toluene, add it into a 250mL dry four-necked flask equipped with a thermometer, condenser, stirrer, and constant pressure funnel, and dissolve 4.8g NaOH in deionized water to form a 30% The aqueous solution was added dropwise using a micro-injector, and the dropping ...

Embodiment 2

[0025] With thermometer, condenser, stirrer, N 2 Into a 250mL dry four-necked flask with an inlet, add 100g of allyl polyether (n=8, m=10) (molecular weight: 990), degass under vacuum at 120°C for 30min, and when the temperature drops to 60°C, add 0.40g of Boron fluoride diethyl ether (catalyst dosage 4‰), using a micro-sampler to drop 10g of epichlorohydrin, the dropping time is controlled within 1 to 2 hours, the control temperature does not rise significantly, and the reaction is continued for 2 hours after the dropping is completed. The unreacted epichlorohydrin was removed under pressure to obtain 108.8 g of the product chlorohydrin ether intermediate with a conversion rate of 90.25%.

[0026] Dissolve the obtained 108.8g chlorohydrin ether intermediate in 80mL toluene, add it into a 500mL dry four-necked flask equipped with a thermometer, condenser, stirrer, and constant pressure funnel, dissolve 6.8g KOH in deionized water, and make 40% The aqueous solution was added d...

Embodiment 3

[0029] With thermometer, condenser, stirrer, N 2 Into a 250mL dry four-neck flask with an inlet, add 80g of allyl polyether (n=2, m=5) (molecular weight: 436), degass under vacuum at 120°C for 30min, and when the temperature drops to 50°C, add 0.72g of di Tin chloride (catalyst dosage 9‰), use a micro-sampler to drop 24g of epichlorohydrin, the dropping time is controlled within 2 to 3 hours, and the temperature is controlled not to rise significantly. After the dropping, continue to react for 3 hours, reduce the pressure The unreacted epichlorohydrin was removed to obtain 97.8 g of the product chlorohydrin ether intermediate, with a conversion rate of 91.28%.

[0030] Dissolve the obtained 97.8g chlorohydrin ether intermediate in 80mL benzene, add it into a 500mL dry four-necked flask equipped with a thermometer, a condenser, a stirrer, and a constant pressure funnel, and add 9.6g NaOH to the flask five times, each interval 20-30min. Stir and control the temperature at 50°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com