Method for producing vinylidene difluoride planar ultrafiltration membrane with gradient structure

A polyvinylidene fluoride and gradient structure technology is applied in the field of preparation of gradient structure polyvinylidene fluoride flat plate ultrafiltration, which can solve the problems of poor membrane strength, low solution concentration, and poor polymer dissolution state, and achieve low shrinkage rate. , the effect of high water flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

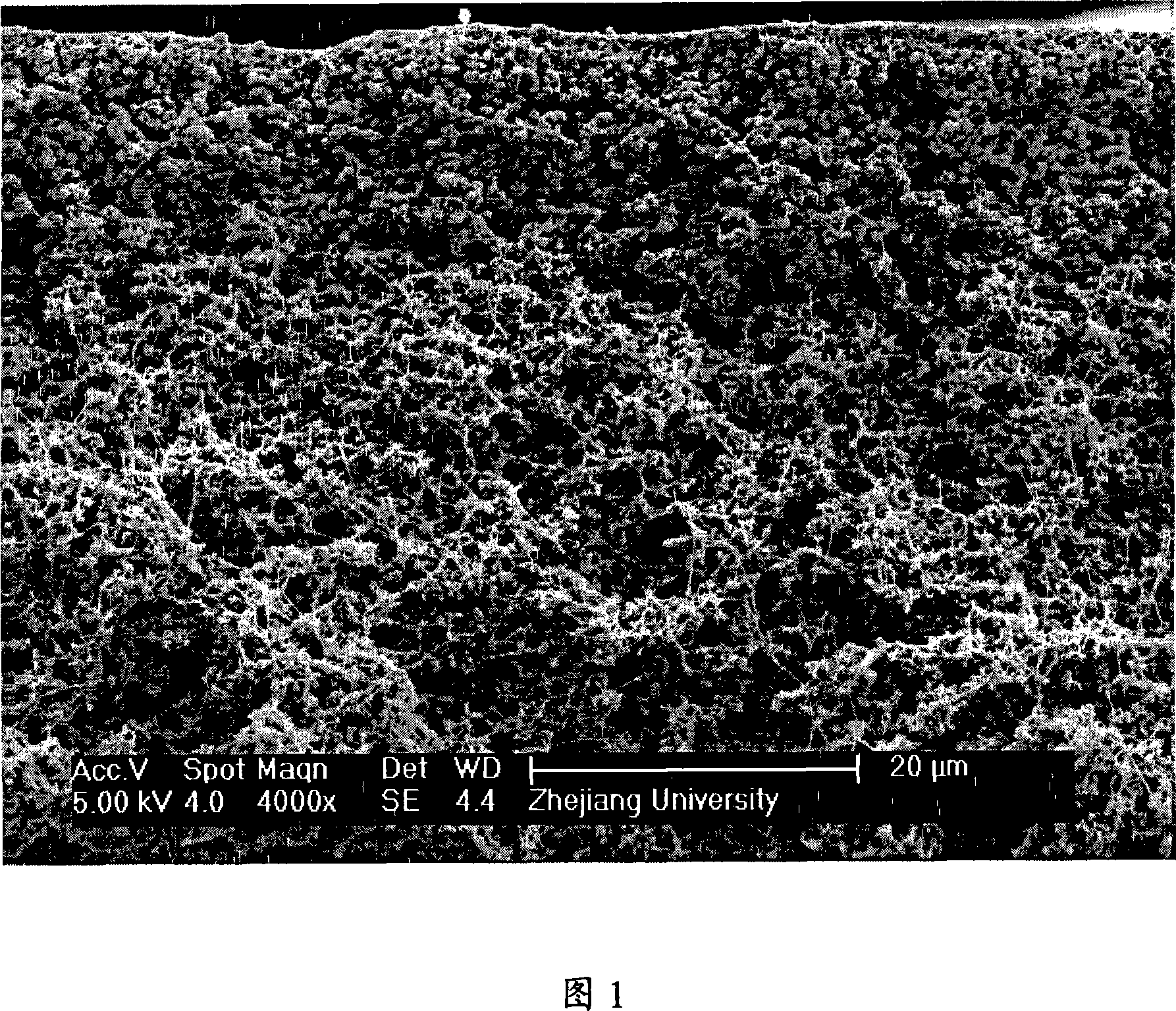

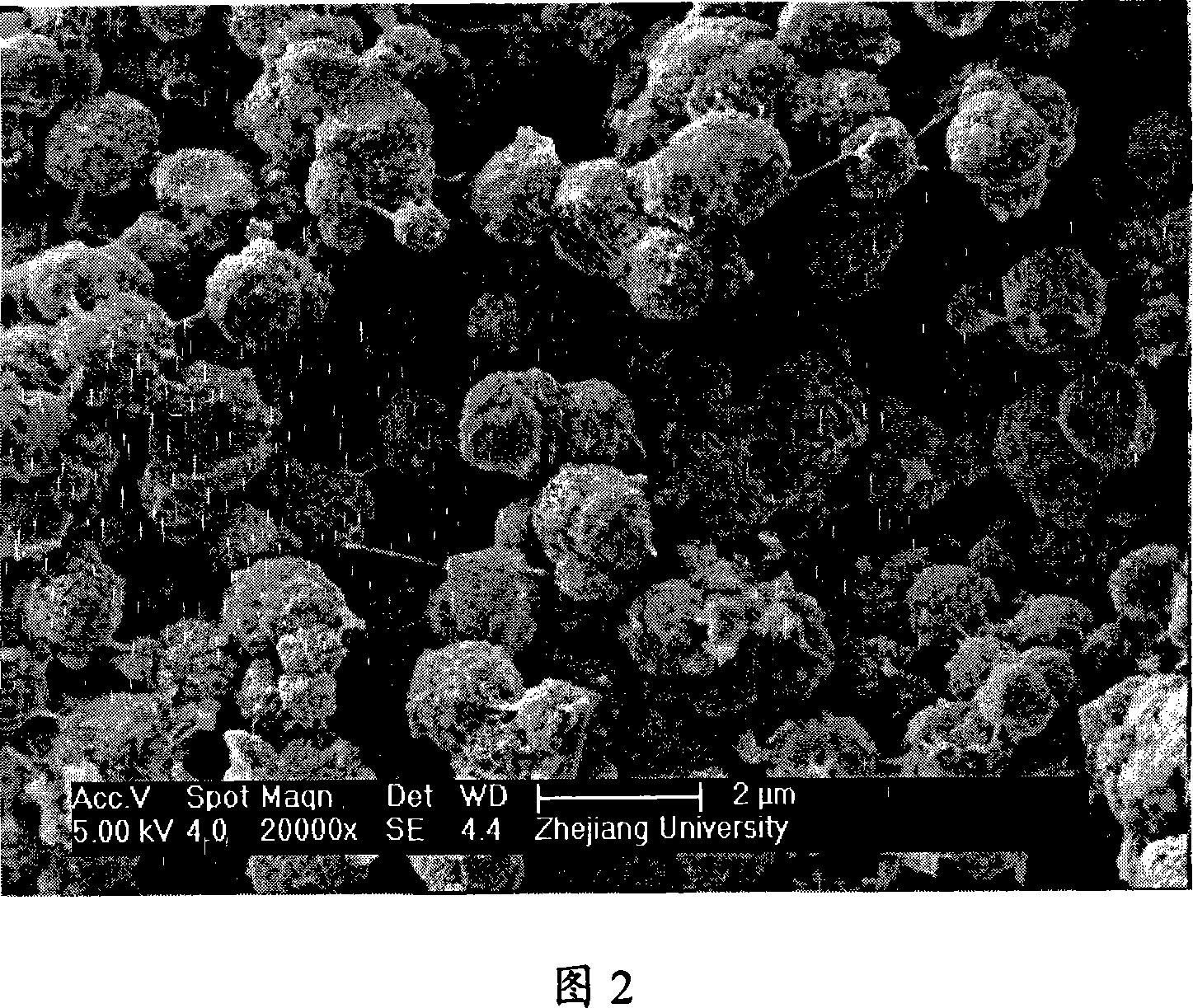

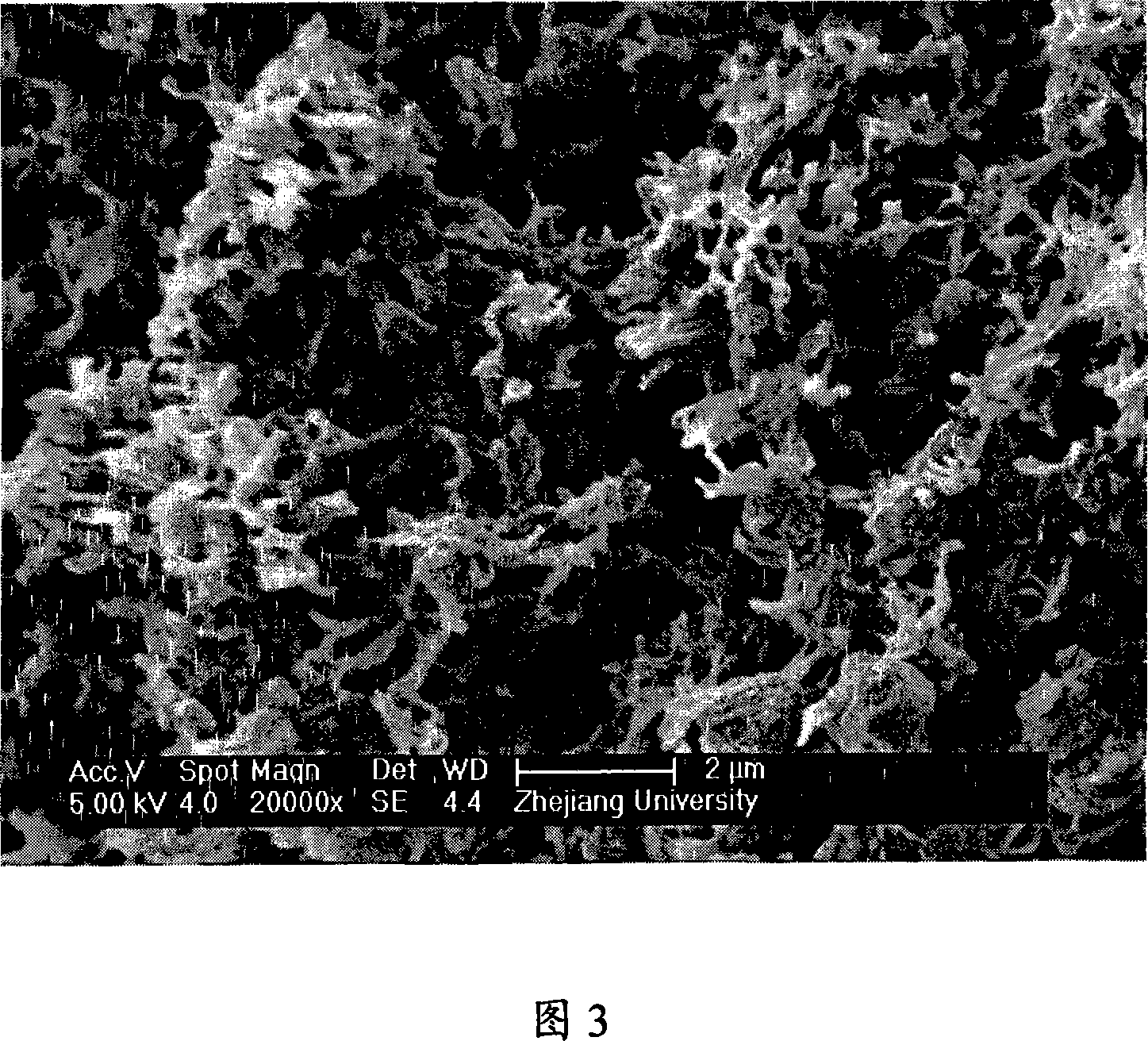

[0030] Dissolve 16g of polyvinylidene fluoride and 1g of lithium chloride in 83g of TEP at 110°C, then place it at room temperature until it reaches a gel state, then place it at 110°C for 5 hours, and finally keep it at 90°C for 5 hours to prepare the product Membrane liquid: filter the film-making liquid, vacuum degassing, scrape-coat it on the non-woven fabric, and place it in the air for 10 seconds; finally, immerse the non-woven fabric coated with the film-making liquid in a deionized water coagulation bath, and coagulate at a low temperature. In the gel stage, the gel temperature is 30° C., and the time is 0.5 hours; in the high-temperature gel stage, the gel temperature is 60° C., and the time is 24 hours. The ultrafiltration membrane with gradient structure was obtained. The resulting membranes were stored in distilled water for a long time until use, or soaked in distilled water for 5 days, soaked in absolute ethanol for 20 hours, and dried in the air.

Embodiment 2

[0032] At 140°C, dissolve 25g of polyvinylidene fluoride in 75gTEP, then place it at room temperature until it reaches a gel state, then place it at 140°C for 1 hour, and finally keep it at 80°C for 1 hour to make a film-making solution; Filtration of the membrane solution, vacuum defoaming, scrape coating on the non-woven fabric, and place it in the air for 120 seconds; finally, immerse the non-woven fabric coated with the membrane-making solution in a deionized water coagulation bath, and the gel temperature in the low-temperature gel stage In the high-temperature gel stage, the gel temperature is 35° C., and the time is 2 hours, and an ultrafiltration membrane with a gradient structure is obtained. The resulting membranes were stored in distilled water for a long time until use, or soaked in distilled water for 5 days, soaked in absolute ethanol for 20 hours, and dried in the air.

Embodiment 3

[0034] At 130°C, 20g of polyvinylidene fluoride was dissolved in 1g of water and 79g of TEP mixed solution, then placed at room temperature until gel state, then placed at 130°C for 1 hour, and finally kept at 80°C for 3 hours to produce Membrane liquid: filter the film-making liquid, vacuum degassing, scrape-coat it on the non-woven fabric, and place it in the air for 30 seconds; finally, immerse the non-woven fabric coated with the film-making liquid in a deionized water coagulation bath, and coagulate at a low temperature. In the gel stage, the gel temperature was 15°C, and the time was 5 hours; in the high-temperature gel stage, the gel temperature was 40°C, and the time was 12 hours, and an ultrafiltration membrane with a gradient structure was obtained. The resulting membranes were stored in distilled water for a long time until use, or soaked in distilled water for 5 days, soaked in absolute ethanol for 20 hours, and dried in the air.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com