Method for repairing explosive polluting soil and underground water

A technology of polluted soil and remediation method, which is applied in the field of environmental pollution control and remediation, can solve the problems of reducing bioavailability and biodegradation efficiency, and achieve the effect of low operating cost, thorough remediation, and no secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

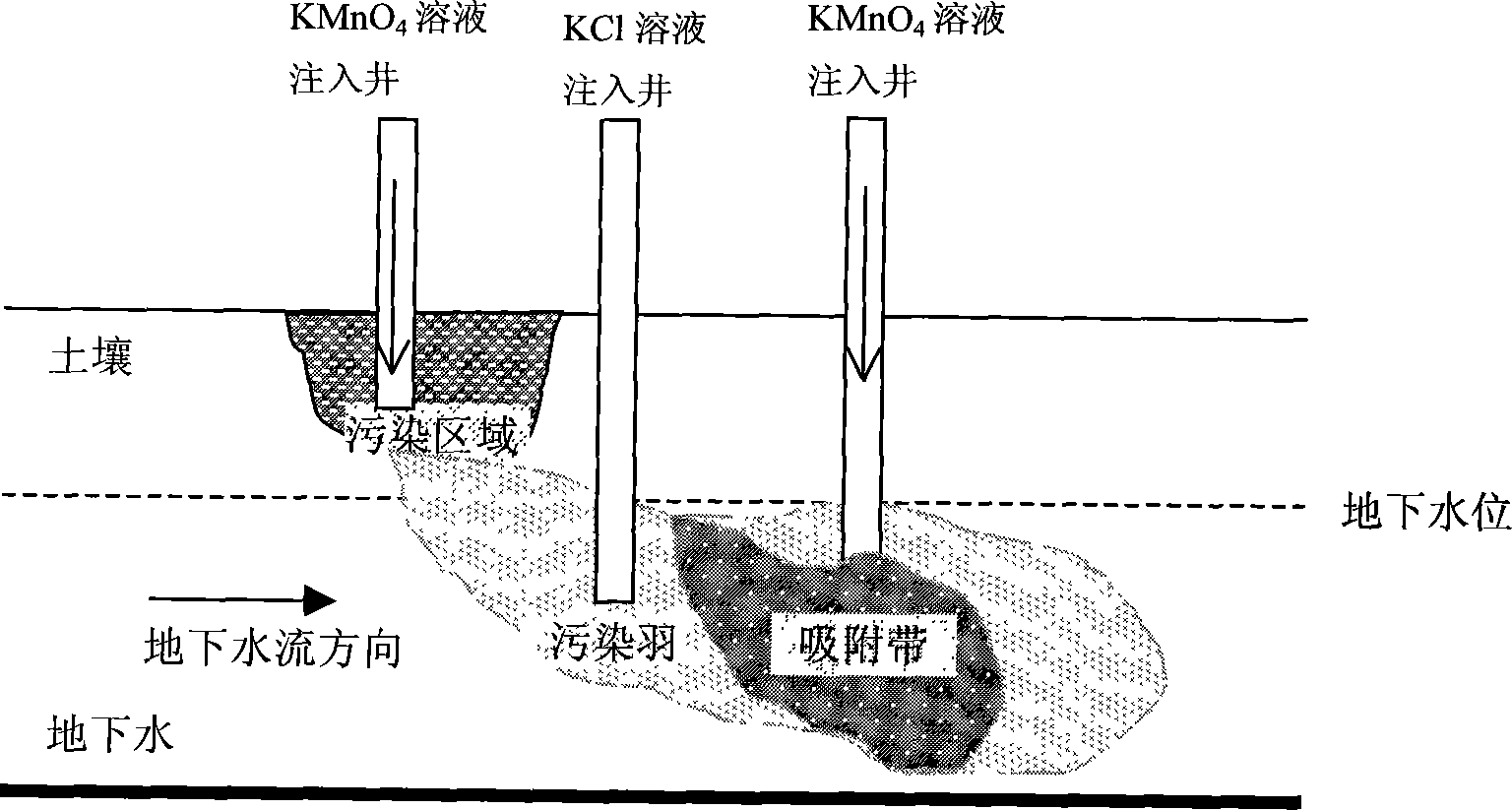

[0014] 1) The pollution plume of TNT polluted groundwater is 1m 3 Inject 0.5mol / L potassium chloride solution at a speed of / h to make K + Clay minerals in ionic groundwater undergo ion exchange to form an adsorption zone to trap TNT explosion pollutants.

[0015] 2) In the adsorption interception zone and the groundwater pollution area, the distance is 1m 3 Inject 50000mg / L potassium permanganate solution at a speed of / h to chemically oxidize and degrade the TNT explosive pollutants in the trapped zone and the polluted area.

Embodiment 2

[0017] 1) The pollution plume of TNT polluted groundwater is 10m 3 Inject 0.05mol / L potassium chloride solution at a speed of / h to make K + Clay minerals in ionic groundwater undergo ion exchange to form an adsorption zone to trap TNT explosion pollutants.

[0018] 2) In the adsorption interception zone and the groundwater pollution area, at a distance of 10m 3 Inject 1000mg / L potassium permanganate solution at a speed of / h to chemically oxidize and degrade the TNT explosion pollutants in the trapped zone and the polluted area.

Embodiment 3

[0020] 1) The pollution plume of TNT polluted groundwater is 2m 3 Inject 0.25mol / L potassium chloride solution at a speed of / h to make K + Clay minerals in ionic groundwater undergo ion exchange to form an adsorption zone to trap TNT explosion pollutants.

[0021] 2) In the adsorption interception zone and the groundwater pollution area, within 2m 3 Inject 25000mg / L potassium permanganate solution at a speed of / h to chemically oxidize and degrade the TNT explosive pollutants in the trapped zone and the polluted area.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com