Self-protective and high-toughness flux-cord welding wire

A flux-cored wire, high toughness technology, used in welding materials, welding oil and gas pipelines, bridges, offshore platforms, high-rise buildings, can solve the problems of not emphasizing welding adaptability of welding wire, low impact toughness of deposited metal, low impact toughness, etc. , to achieve good all-position weldability, improve low temperature impact toughness, and low cost of welding wire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] By adopting the chemical composition and preparation method of the high-toughness self-shielding flux-cored wire for all-position welding of the present invention, 6 batches of welding wires were prepared, and the diameter of the above-mentioned welding wires was 2.0 mm.

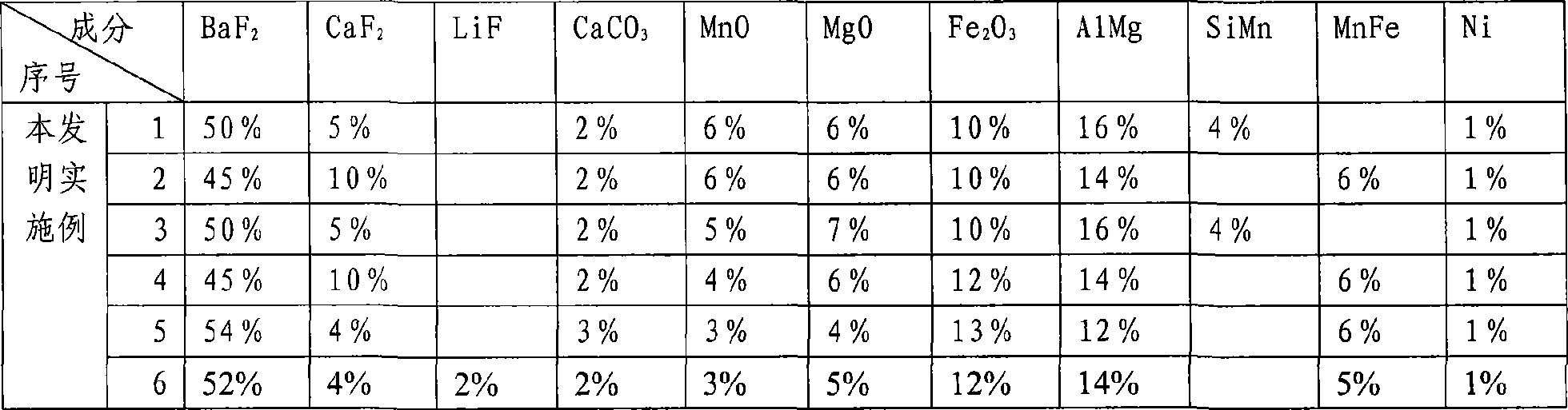

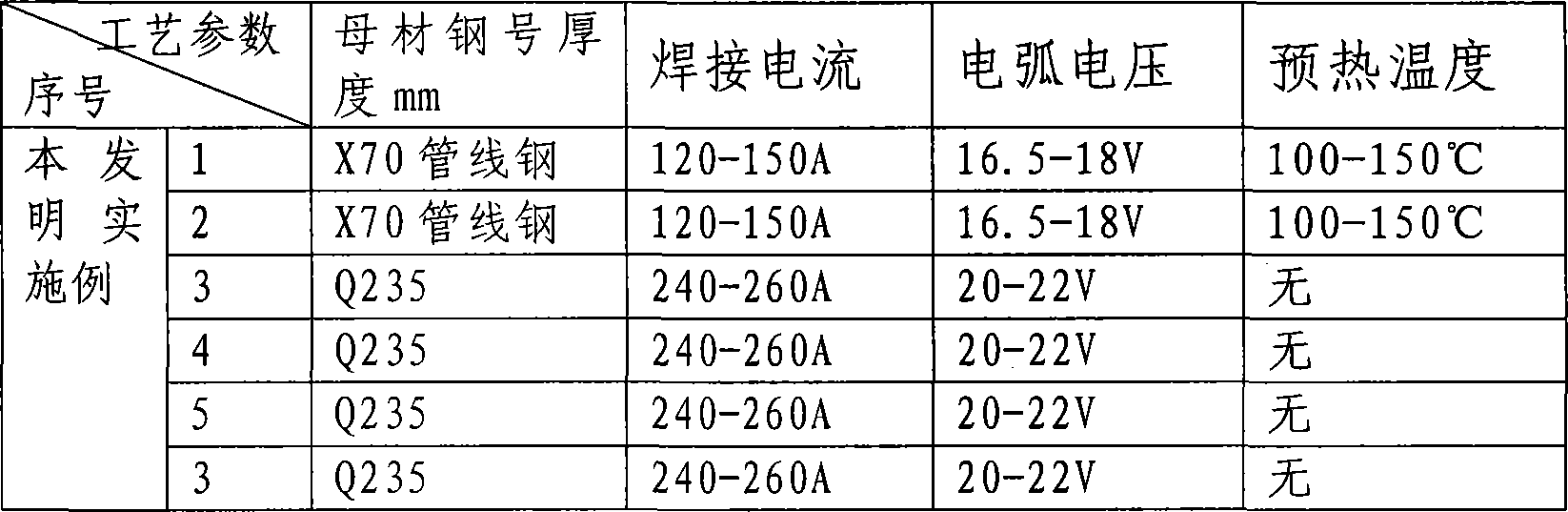

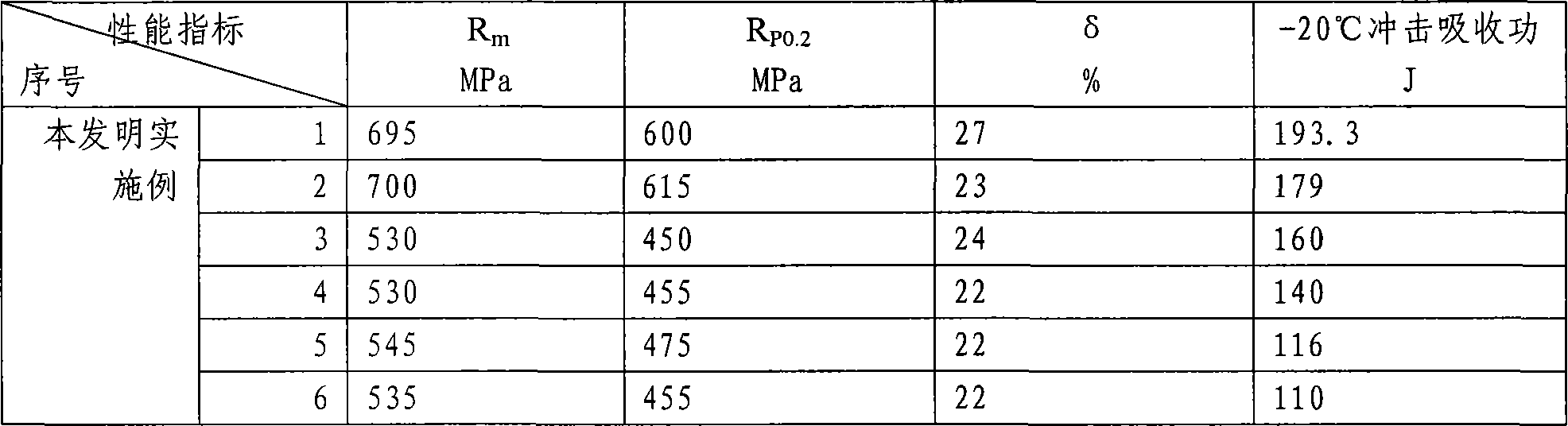

[0024] Table 1 is the chemical composition list of the high-toughness self-shielding flux-cored welding wire used for all-position welding of the present invention, Table 2 is the chemical composition list of the steel strip of the present invention, and Table 3 is the flux-cored wire welding base material and welding process table used in the embodiments of the present invention, Table 4 shows the properties of the deposited metal after welding according to the embodiment of the present invention.

[0025] Table 1 is the chemical composition table of the all-position self-shielding flux-cored welding wire of the present invention (weight %)

[0026]

[0027] Element

C

Si

mn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com