Multifunctional electronic jacquard double-sided circular weft braiding machine controlled by computer

An electronic jacquard and multi-functional technology, which is applied to jacquard machines, circular machines for weft knitting with individual moving needles, and weft knitting knitting. It can solve the problems of less variety changes, no automatic opening ribs, and low-grade products. , to achieve the effect of increasing the variety of fabric designs and colors, saving raw material costs, and saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

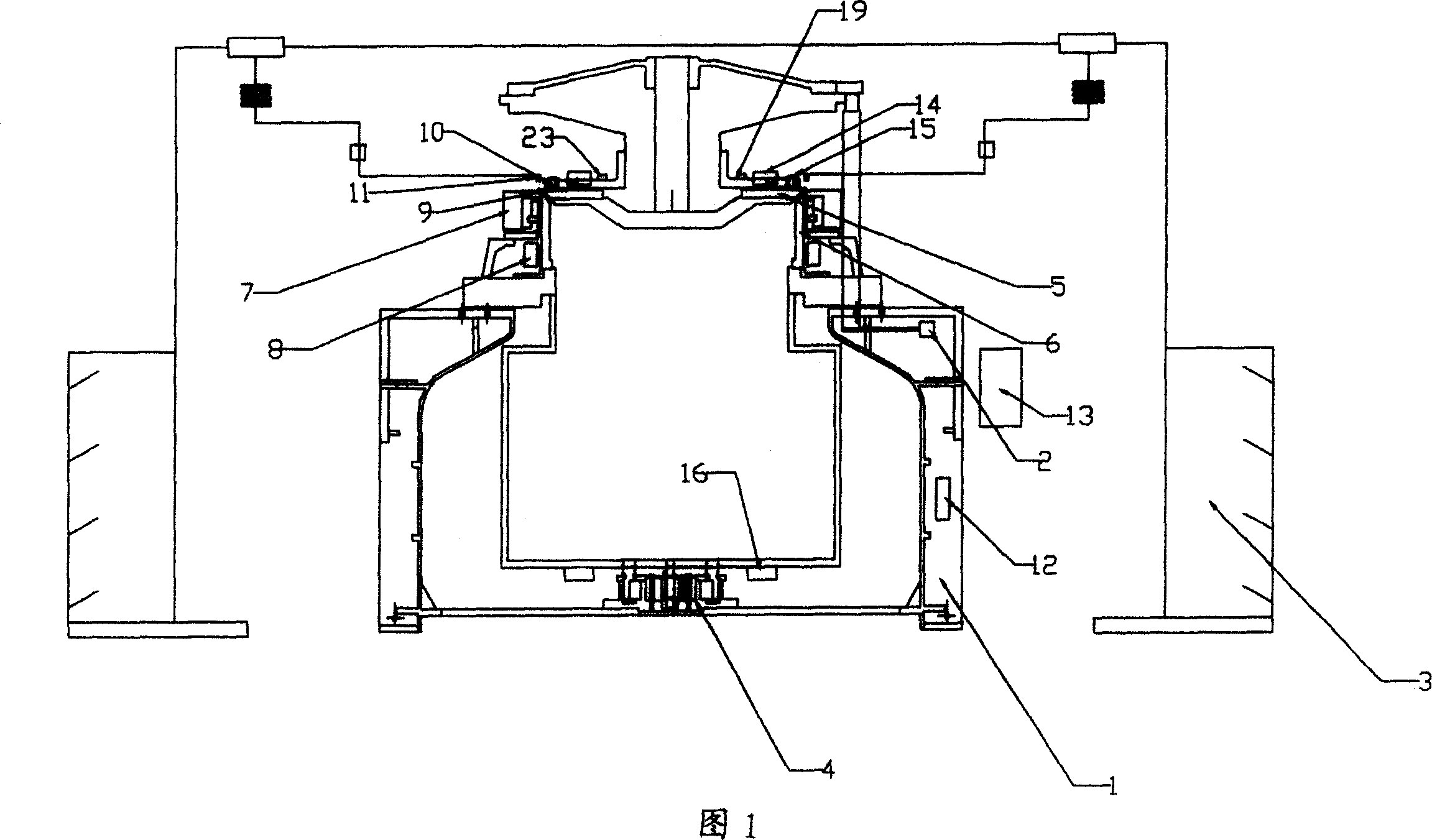

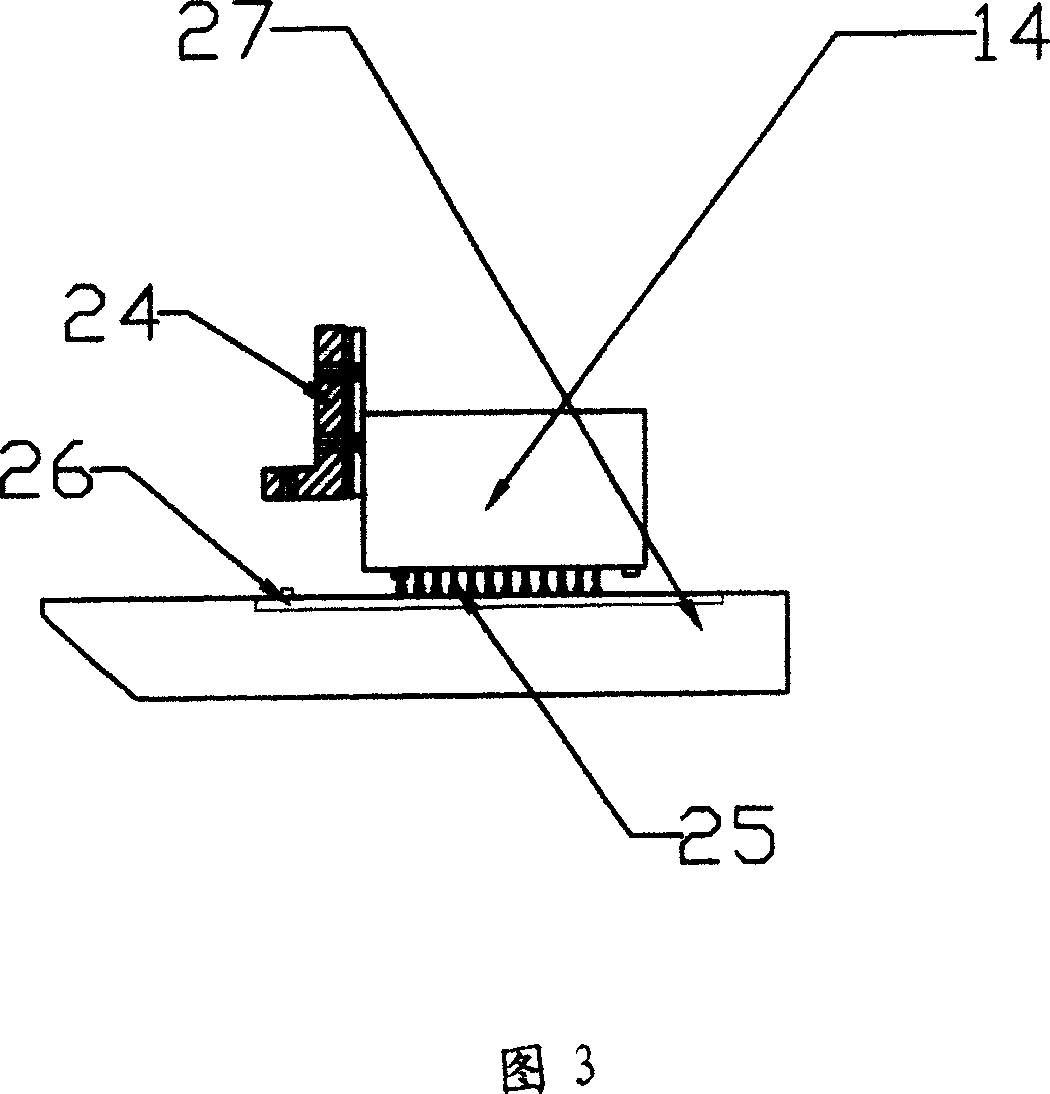

[0010] Embodiment 1: As shown in Figure 1, the fully computer-controlled multifunctional electronic jacquard double-sided circular weft knitting machine includes a frame 1, a main motor 2, a creel 3, a fabric roll frame 4, an upper needle cylinder 5, and a lower needle Cylinder 6, automatic thread changing pneumatic scissors 7, lower needle selector 8, knitting part 9, fabric density adjustment mechanism 10, fault alarm device 11, frequency converter 12, main computer 13, upper needle selector 14, stepping motor 15, Torque motor 16 and sensor 23, fault alarm device 11, automatic line-changing pneumatic scissors 7, upper needle selector 14 and lower needle selector 8 are respectively connected with main computer 13, main motor 2 is connected with main computer 13 through frequency converter 12, The fabric density adjusting mechanism 10 is connected with the main computer 13 through the stepper motor 15 arranged thereon, and the cloth roll frame 4 is connected with the main compu...

Embodiment 2

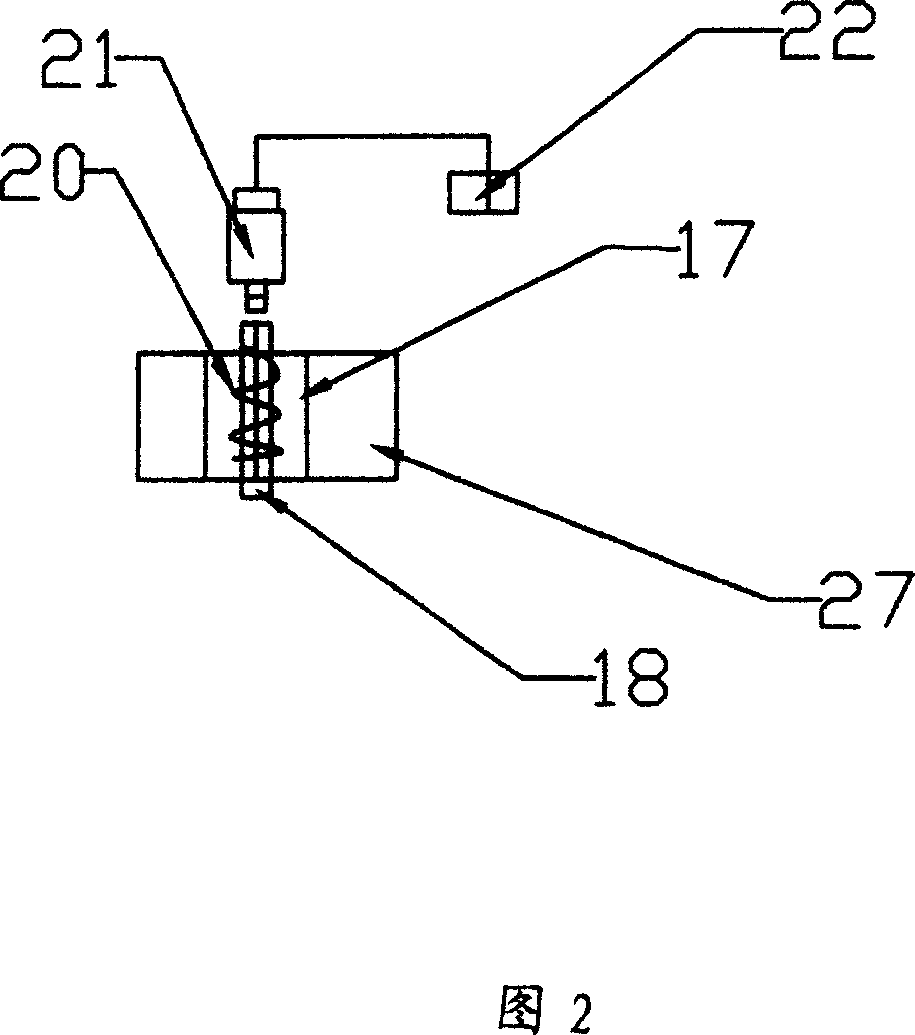

[0011] Embodiment 2: As shown in Figure 2, the fully computer-controlled multifunctional electronic jacquard double-sided circular weft knitting machine also includes a movable cam switching mechanism 17, and the movable cam switching mechanism 17 is composed of a cam 18, a cam seat 19, a return spring 20, Composed of cylinder 21 and electromagnetic valve 22, triangle 18 is arranged in triangle seat 19, return spring 20 is arranged between triangle 18 and triangle seat 19, cylinder 21 bears triangle 18, solenoid valve 22 is respectively connected with cylinder 21 and main computer 13 Connect, all the other are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com