Nonprotein nitrogen feed additive suitable for ruminant and its producing process

A feed additive, non-protein nitrogen technology, applied in the field of animal feed, can solve the problems of poor palatability of urea and ammonia poisoning, and achieve the effects of sufficient inclusion, reducing loss and avoiding ammonia poisoning in animals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Recipe: urea 500g, cornstarch 480g, gelatin 20g

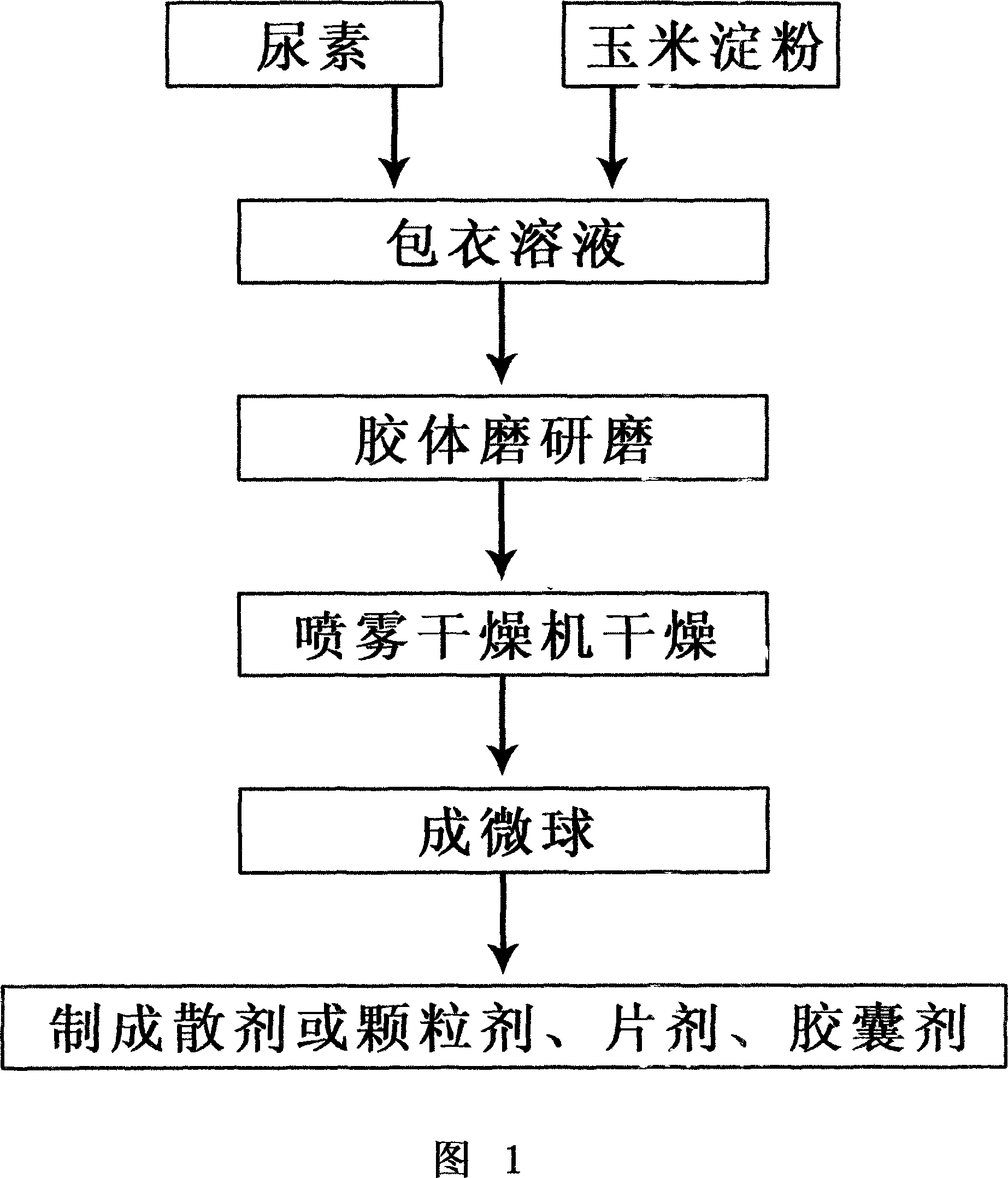

[0016] Preparation method: disperse urea and cornstarch evenly in gelatin solution, grind into emulsion with colloid mill, and dry in spray dryer at room temperature to form microspheres to obtain the finished product. It can also be made into powder or granules, tablets, capsules, etc.

Embodiment 2

[0018] Formula: 500g urea, 450g corn starch, 50g sodium carboxymethylcellulose

[0019] Preparation method: completely consistent with Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com