Crystal diabetin manufacturing technique on vertical type continuous crystallizer

A technology for crystallization of fructose and production process, which is applied in the field of preparation of organic compounds, can solve the problems of waste of tank volume and long crystallization cycle, and achieves the effects of shortening crystallization cycle, stable production process and continuous production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

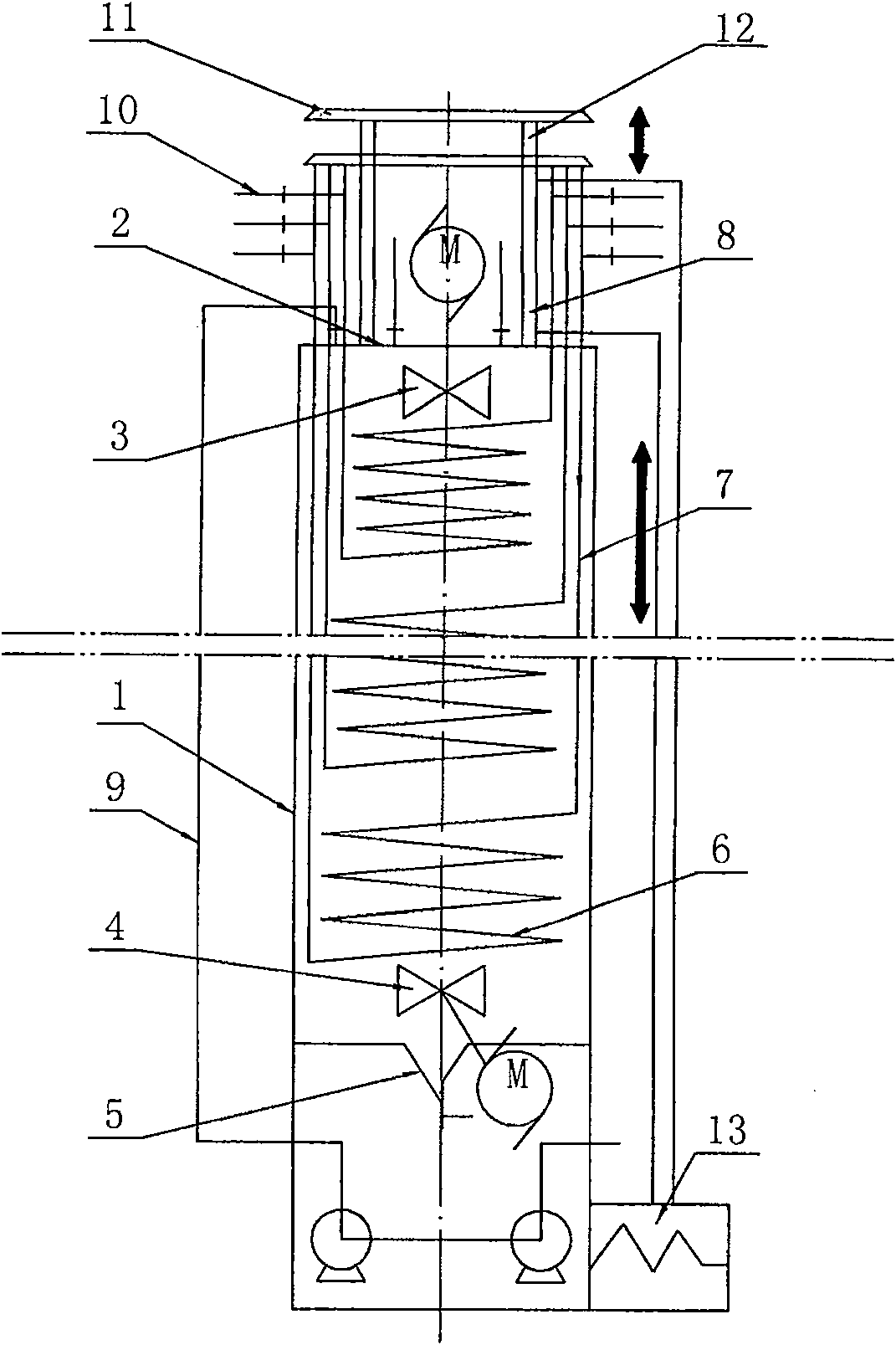

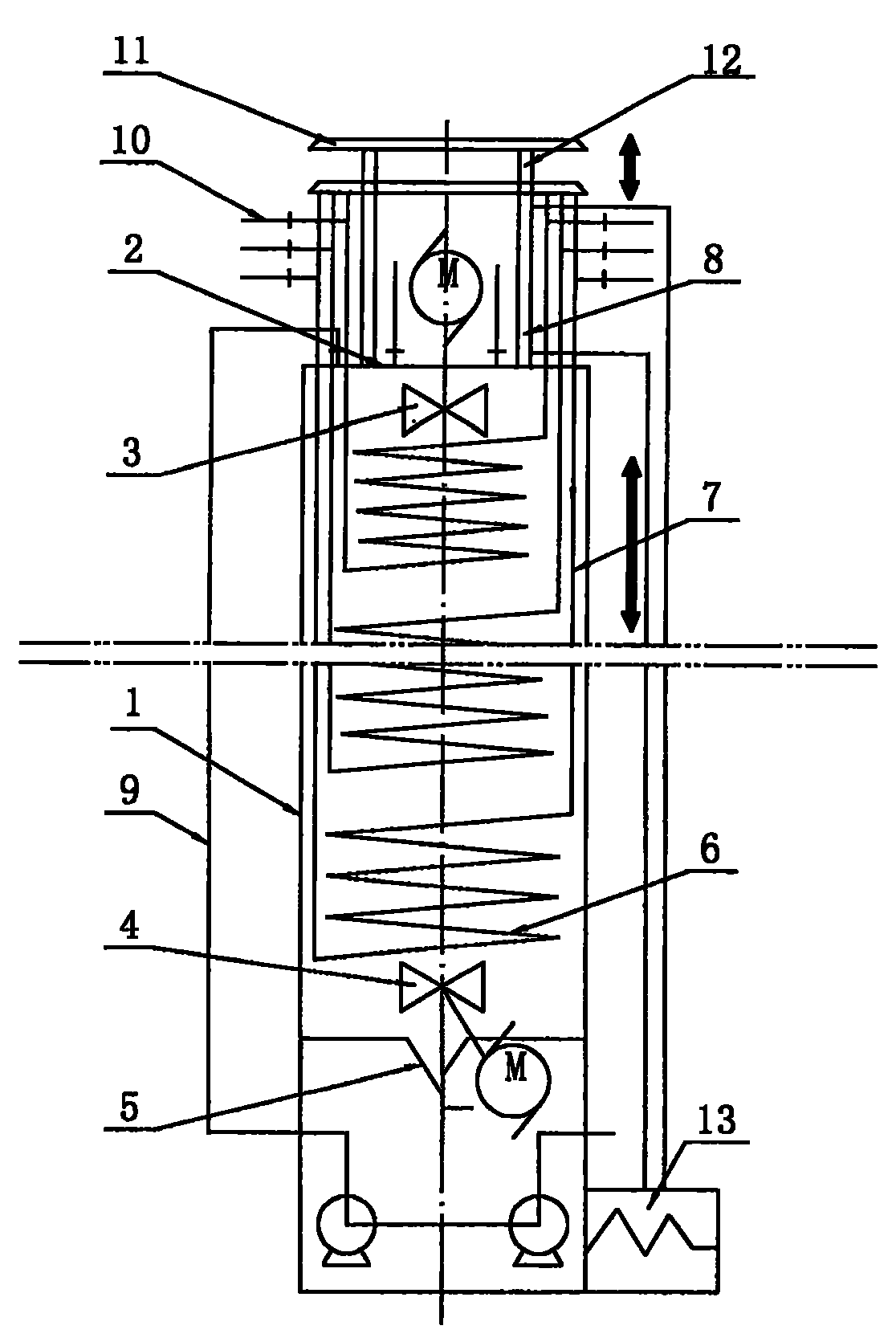

[0034] The technical solution of the present invention will be further specifically described below in conjunction with the accompanying drawings.

[0035] see figure 1 As shown, the existing vertical continuous crystallizer, its multi-stage coil vibrating continuous cooling crystallizer structure includes a shell 1, a flat cover 2, a material distribution device 3, a scraping device 4, a conical head 5, a cooling plate Tube 6; its shell 1 is a vertical cylindrical container, and multiple sets of cooling coils 6 are arranged in the shell 1, and multiple sets of cooling coils 6 are respectively connected with cooling medium distribution pipes 10, forming multiple sets from top to bottom The single crystallizers connected in sequence are equivalent to multiple coil heat exchangers, which remove the heat of crystallization and other mixing heat to complete the cooling and crystallization of materials. The multi-group cooling coils 6 are composed of multi-layer polygons wound by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com