Ozone sterilization device and method for disinfecting sterilizing used for the said sterilizing device

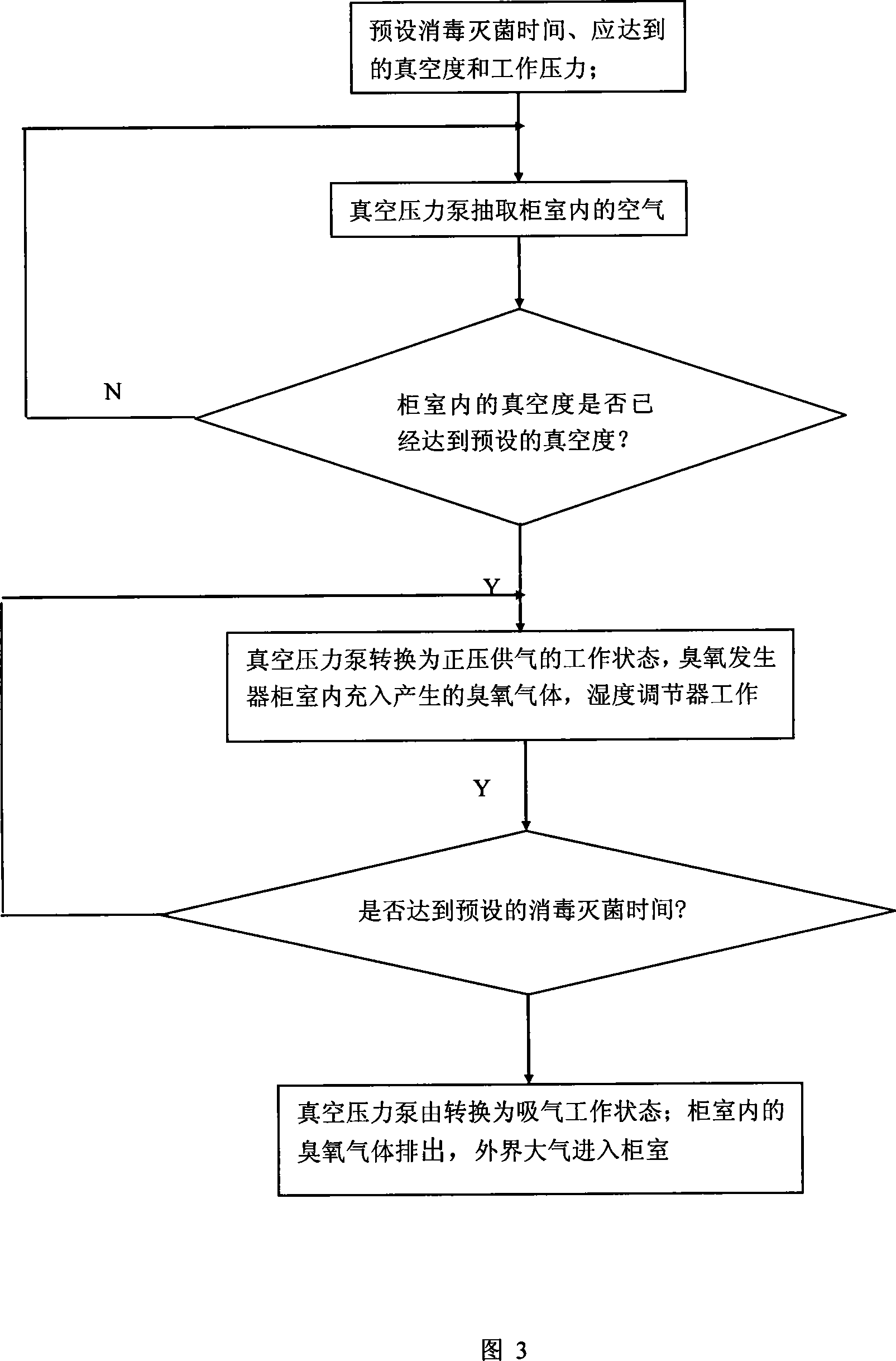

A technology of ozone sterilization and sterilization method, applied in the field of ozone sterilization device and disinfection and sterilization, can solve the problems of influence of sterilization effect, secondary pollution, failure to meet sterilization requirements, etc., so as to improve the effect of ozone sterilization , Low operating cost and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

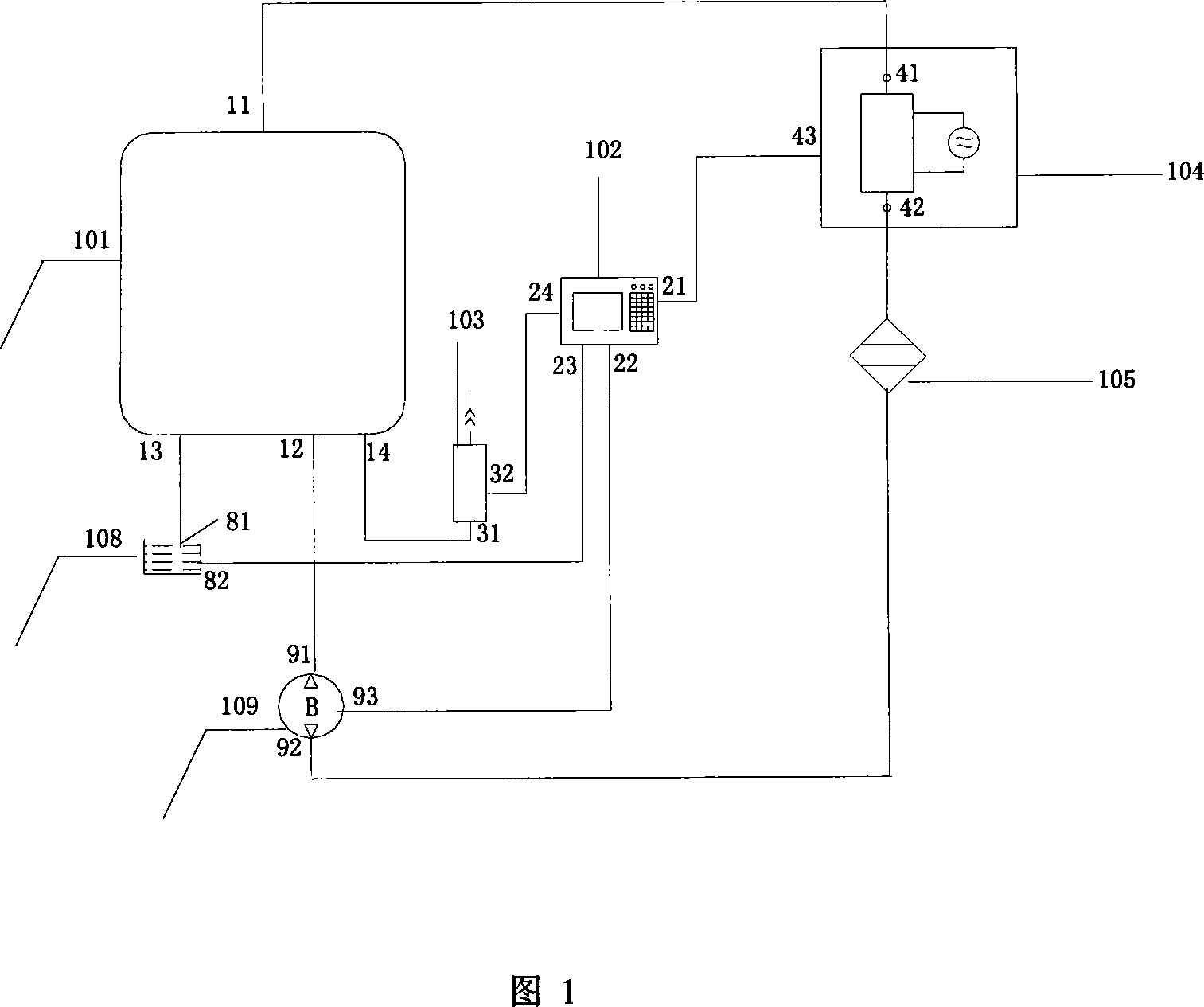

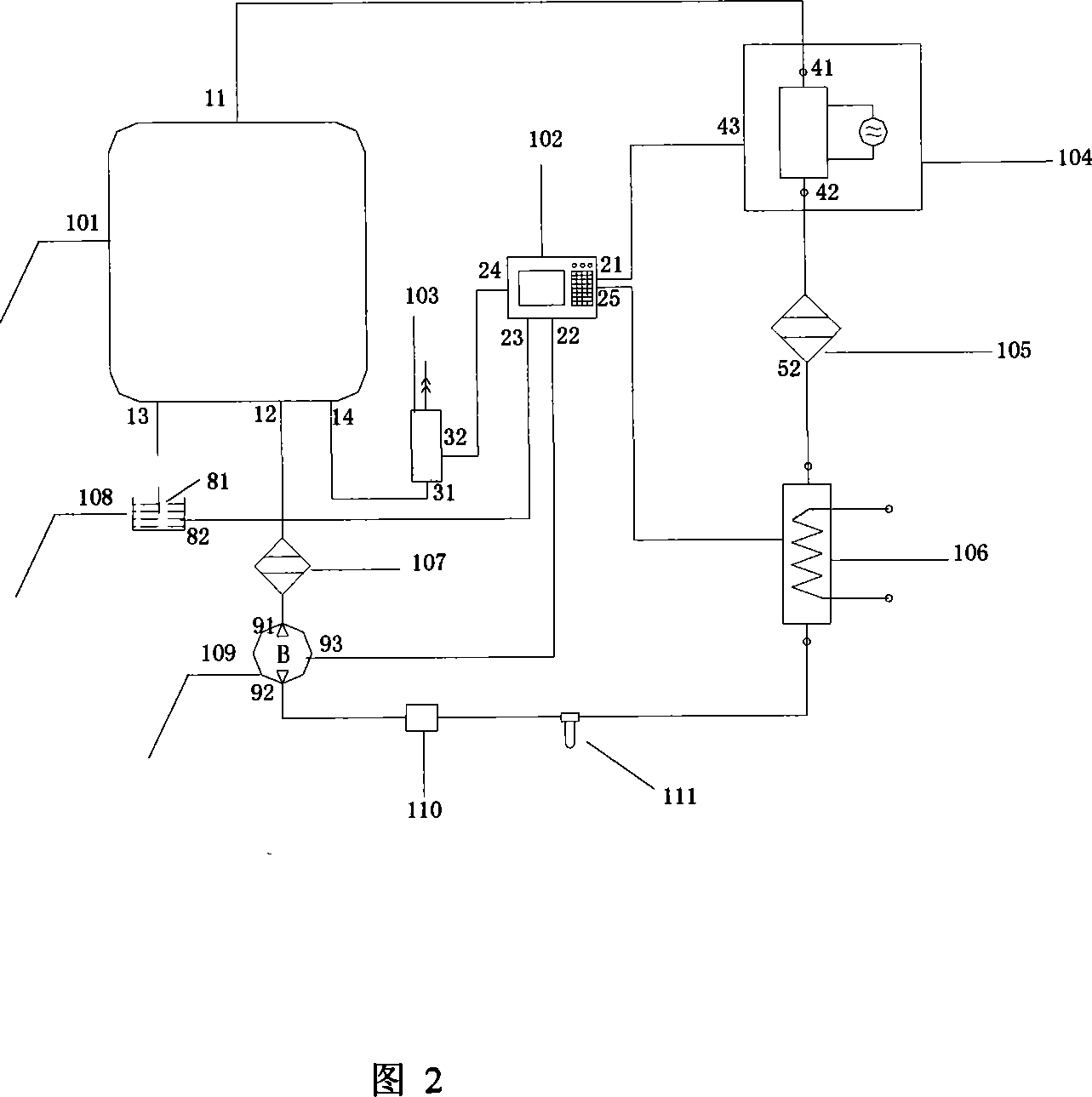

[0028] As shown in Figure 1, the gas outlet 12 of the ozone sterilizing device cabinet chamber 101 is connected with the suction port 91 of the vacuum pressure pump 109, and the gas inlet 11 of the cabinet chamber 101 is connected with the gas outlet 41 of the ozone generator 104, in vacuum The sterilization filter 105 is connected in series between the pressure pump 109 and the ozone generator 104 to form a closed circuit; the humidification port 13 of the cabinet room 101 is connected with the moisture outlet port 81 of the humidity regulator 108, and the tail gas of the cabinet room 101 is discharged Mouth 14 is connected with the inlet end 31 of ozone tail gas decomposer 103; The first control output end 21 of PLC controller 102 is connected the power supply output end 43 of ozone generator 104, and the second control output end 22 of PLC controller 102 is connected vacuum The power supply output 93 of the pressure pump 109, the third control output 23 of the PLC controller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com