Desulfurization and transformation method for waste lead accumulator regenerative lead

A waste lead-acid battery, desulfurization conversion technology, applied in the chemical industry, can solve the problems of complex process and high cost of waste lead-acid battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

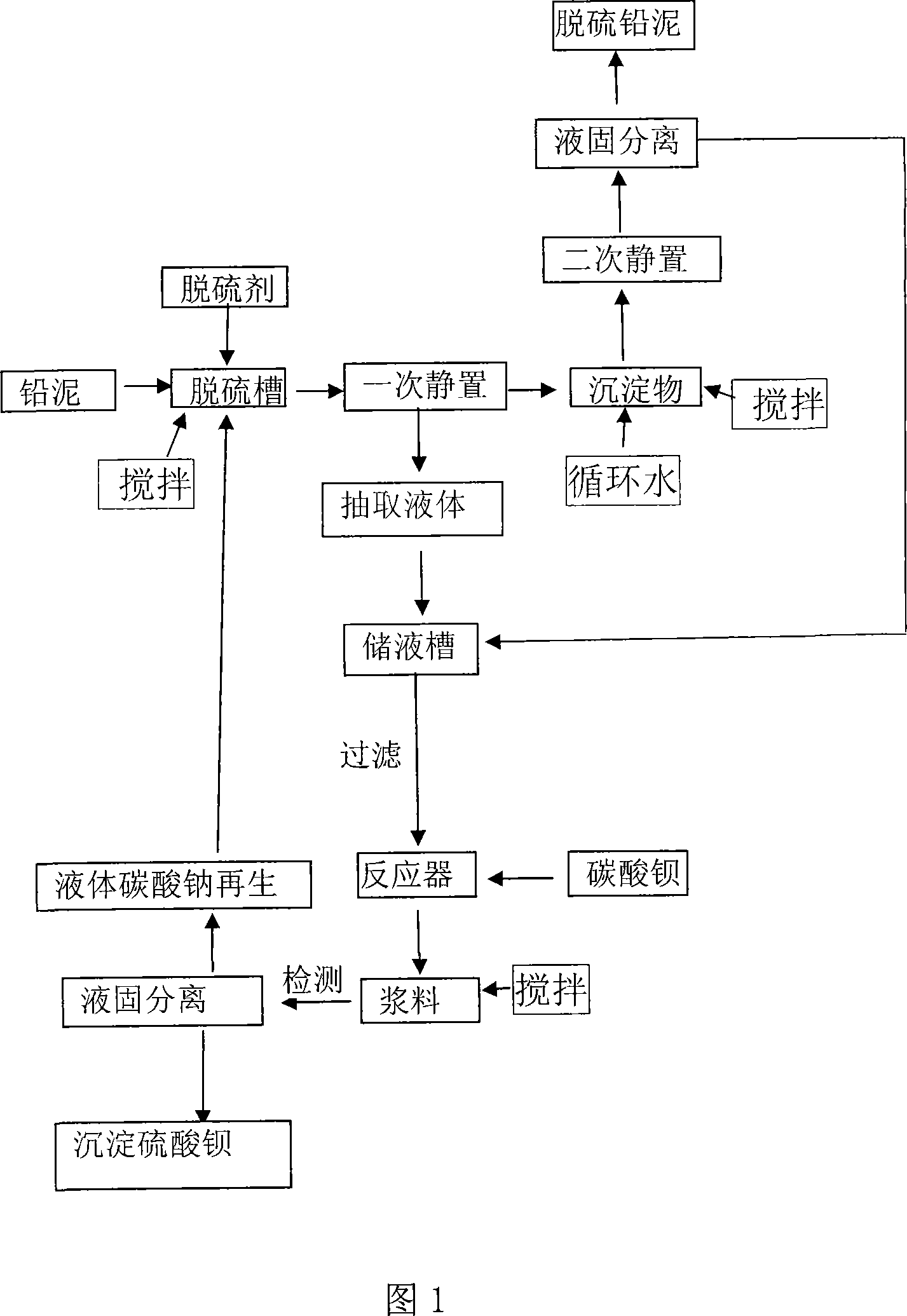

[0013] As shown in Fig. 1, a kind of desulfurization conversion method of the regenerated lead of waste lead storage battery of the present invention comprises a process that waste lead storage battery is crushed, and the lead mud slurry material produced after crushing carries out liquid-solid separation to produce wet lead mud, wet lead Put the mud into a desulfurization tank, put the desulfurizing agent sodium carbonate in the desulfurization tank, and stir it. After fully reacting, let it stand for liquid-solid separation to obtain precipitate lead carbonate and liquid sodium sulfate. Liquid sulfuric acid Sodium is put into a reactor, barium carbonate is added in the reactor, stirred, after fully reacting, stand still, carry out liquid-solid separation, obtain precipitate barium sulfate and liquid sodium carbonate, described liquid sodium carbonate is sent into desulfurization In the tank, it is recycled as a desulfurizer.

[0014] Further, in the first desulfurization pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com