Tungsten carbide particle enhanced steel/iron-base composite wearable plate and preparation technique thereof

A technology of tungsten carbide particles and iron-based composite materials, which is applied in the field of tungsten carbide particle-reinforced steel/iron-based composite wear-resistant plates and its preparation technology, can solve the problems of unrealizable workpieces, many casting defects, and high requirements, and achieve cost Low cost, low equipment investment, and the effect of improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

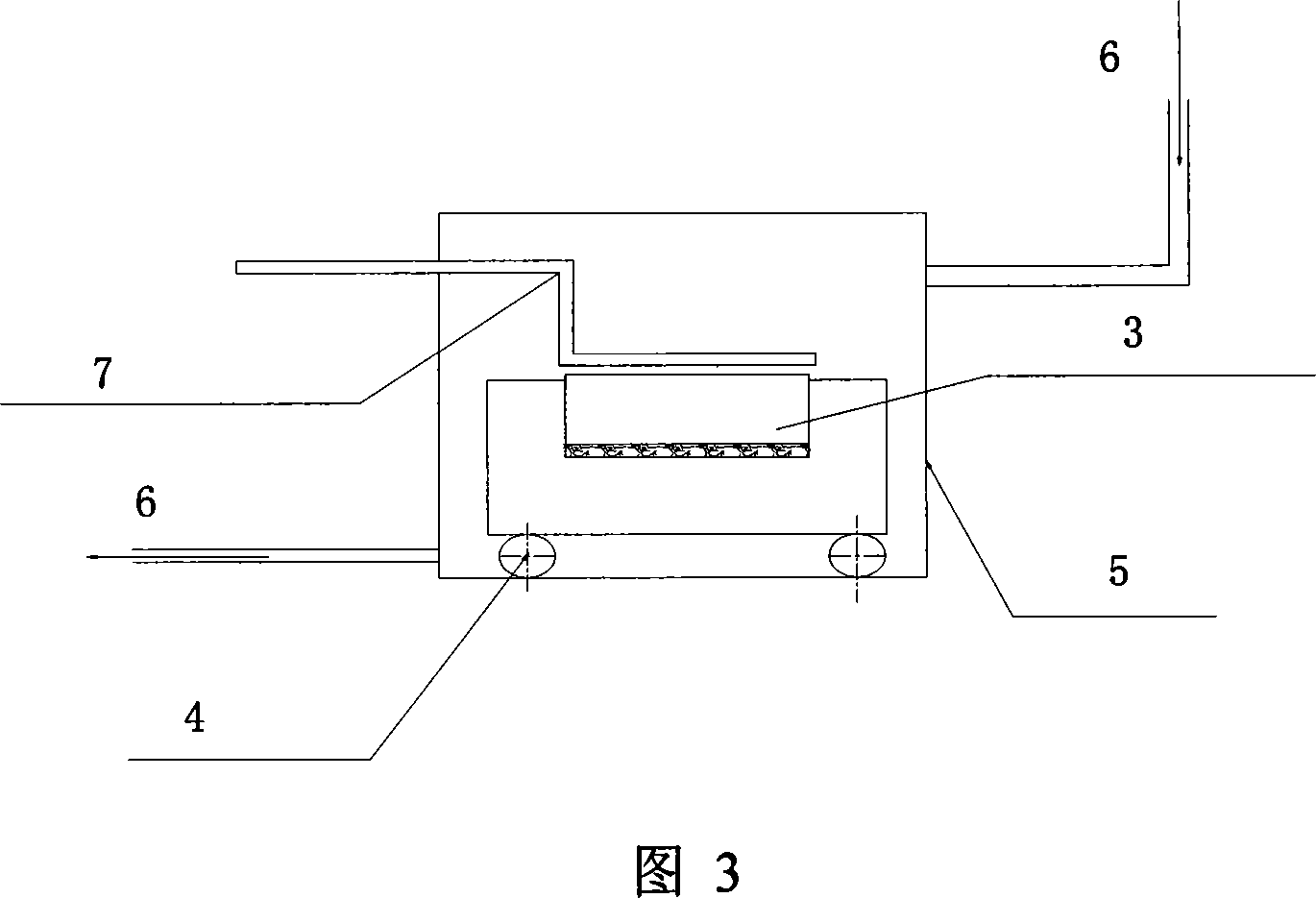

[0033] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0034] Take the preparation of tungsten carbide particles reinforced high manganese steel matrix composite wear-resistant plates with a size of 50×15×1000mm as an example.

[0035] The preparation process steps of the present embodiment are as follows:

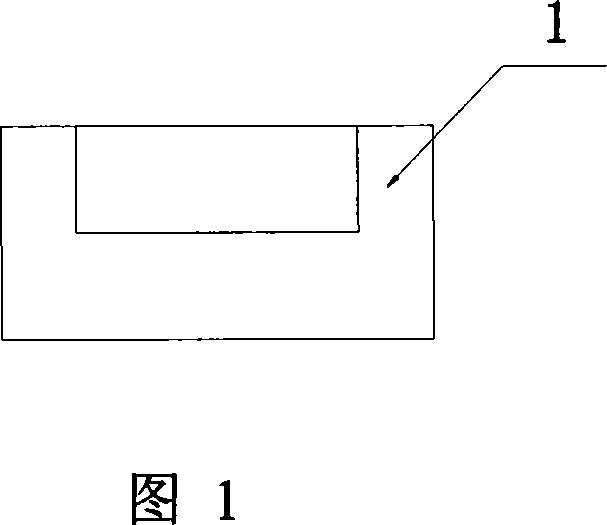

[0036] A: To make the sand mold, the sand mold (1) has an external dimension of 70×30×1100mm. In order to ensure the subsequent steps, the size of the middle groove should be slightly larger than the size of the required composite plate: 52×17×1004mm. As shown in Figure 1, brush the cast steel paint and dry it for later use.

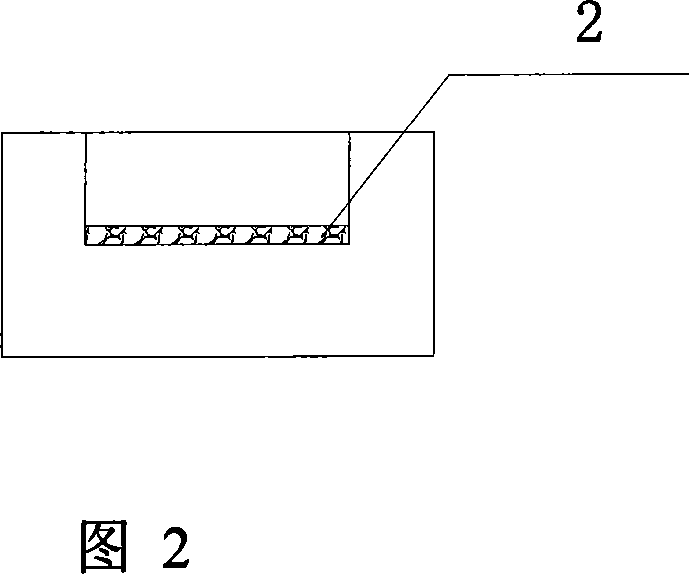

[0037] B: The WC powder is mixed and ball milled for 6 hours according to the volume ratio of -2.5~+2mm: 30%; -2~+1mm: 40%; -1~+0.3mm: 30%, and the mixed powder is uniform Cover the bottom of the sand mold groove, and use a vernier caliper to control the thickness of the WC powder layer (2) be...

Embodiment 2

[0041] Take the preparation of tungsten carbide particle reinforced 45# steel matrix composite wear-resistant plate with a size of 70×20×1000mm as an example.

[0042] The preparation process steps of the present embodiment are as follows:

[0043] A: To make the sand mold, the sand mold (1) has an external dimension of 100×40×1100mm. In order to ensure the subsequent steps, the size of the middle groove should be slightly larger than the size of the required composite plate: 72×22×1004mm. As shown in Figure 1, brush the cast steel paint and dry it for later use.

[0044] B: The WC powder is mixed and ball milled for 6 hours according to the volume ratio of -2.5~+2mm: 40%; -2~+1mm: 30%; -1~+0.3mm: 30%, and the mixed powder is uniform Cover the bottom of the sand mold groove, and use a vernier caliper to control the thickness of the WC powder layer (2) between 2 and 3 mm, as shown in Figure 2.

[0045]C: Cut the 45# steel plate (3) with a thickness of 70×19×1000mm, place it o...

Embodiment 3

[0048] Take the preparation of tungsten carbide particles reinforced high chromium cast iron matrix composite wear-resistant plates with a size of 70×20×1000mm as an example.

[0049] The preparation process steps of the present embodiment are as follows:

[0050] A: To make the sand mold, the sand mold (1) has an external dimension of 100×40×1100mm. In order to ensure the subsequent steps, the size of the middle groove should be slightly larger than the size of the required composite plate: 72×22×1004mm. As shown in Figure 1, brush the cast iron paint and dry it for later use.

[0051] B: The WC powder is mixed and ball milled for 6 hours according to the volume ratio of -2.5~+2mm: 35%; -2~+1mm: 40%; -1~+0.3mm: 25%, and the mixed powder is uniform Cover the bottom of the sand mold groove, and use a vernier caliper to control the thickness of the WC powder layer (2) between 2 and 3mm, as shown in Figure 2.

[0052] C: Cut out a 70×19×1000mm thick high-chromium cast iron plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com