Technical method by using seawater to remove sulfur dioxide in smoke through membrane absorption method

A technology of sulfur dioxide and process methods, which is applied in the direction of chemical instruments and methods, separation methods, and separation of dispersed particles. It can solve the problems of large area occupied by packed towers, high operating costs, and inflexible installation, and achieves convenient operation and low space occupation. Small, flexible installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

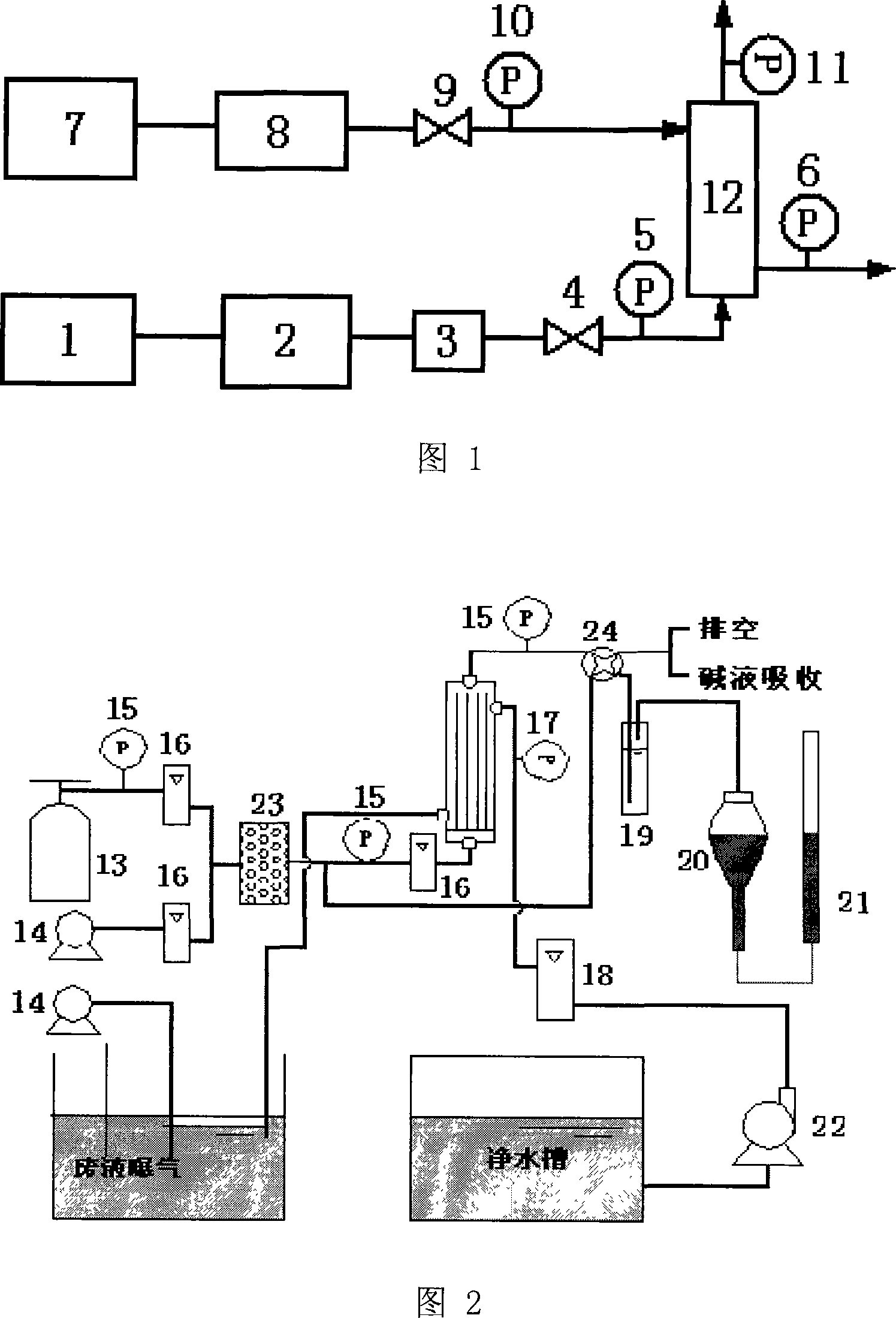

[0027] Embodiments of the process method of the present invention will be described in detail below in conjunction with the technical scheme and accompanying drawings.

[0028] As shown in Figure 2, the hydrophobic hollow fiber membrane absorber is composed of 64 hydrophobic polypropylene hollow fiber ultrafiltration membranes with an outer diameter of 600 μm and an inner diameter of about 500 μm filled in a glass tube with a diameter of 10 mm and an effective length of 220 mm. made by law. The micropore size on the surface of the membrane filament is 0.07-0.1 μm, and the wall thickness of the membrane filament is 50 μm.

[0029] The experimental gas consists of air and SO 2 Mixed to simulate flue gas, where the air is compressed by the air pump and dried by the drying tube, SO 2 Released from the steel cylinder, the two are mixed evenly by the mixer, and then enter the hollow fiber inner tube side of the membrane absorber; the absorption liquid enters the shell side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com