Composite oxygen penetrating ceramics membrane, preparation method, and application

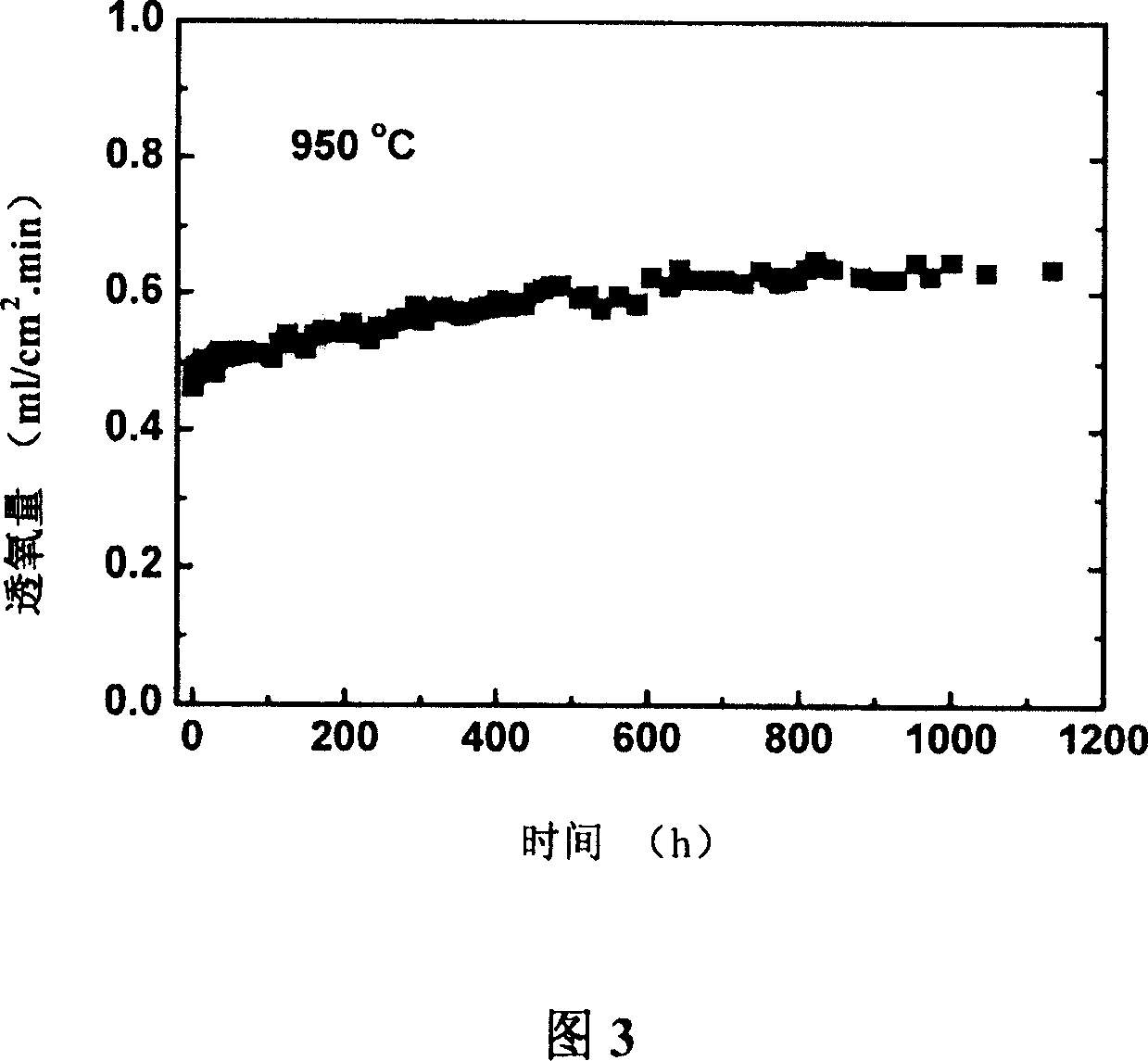

A ceramic membrane and oxide technology, applied in the field of composite oxygen-permeable ceramic membrane, can solve the problems of material performance impact, low oxygen permeability, high material tension, etc., to achieve high structural stability, high chemical stability, high oxygen permeability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

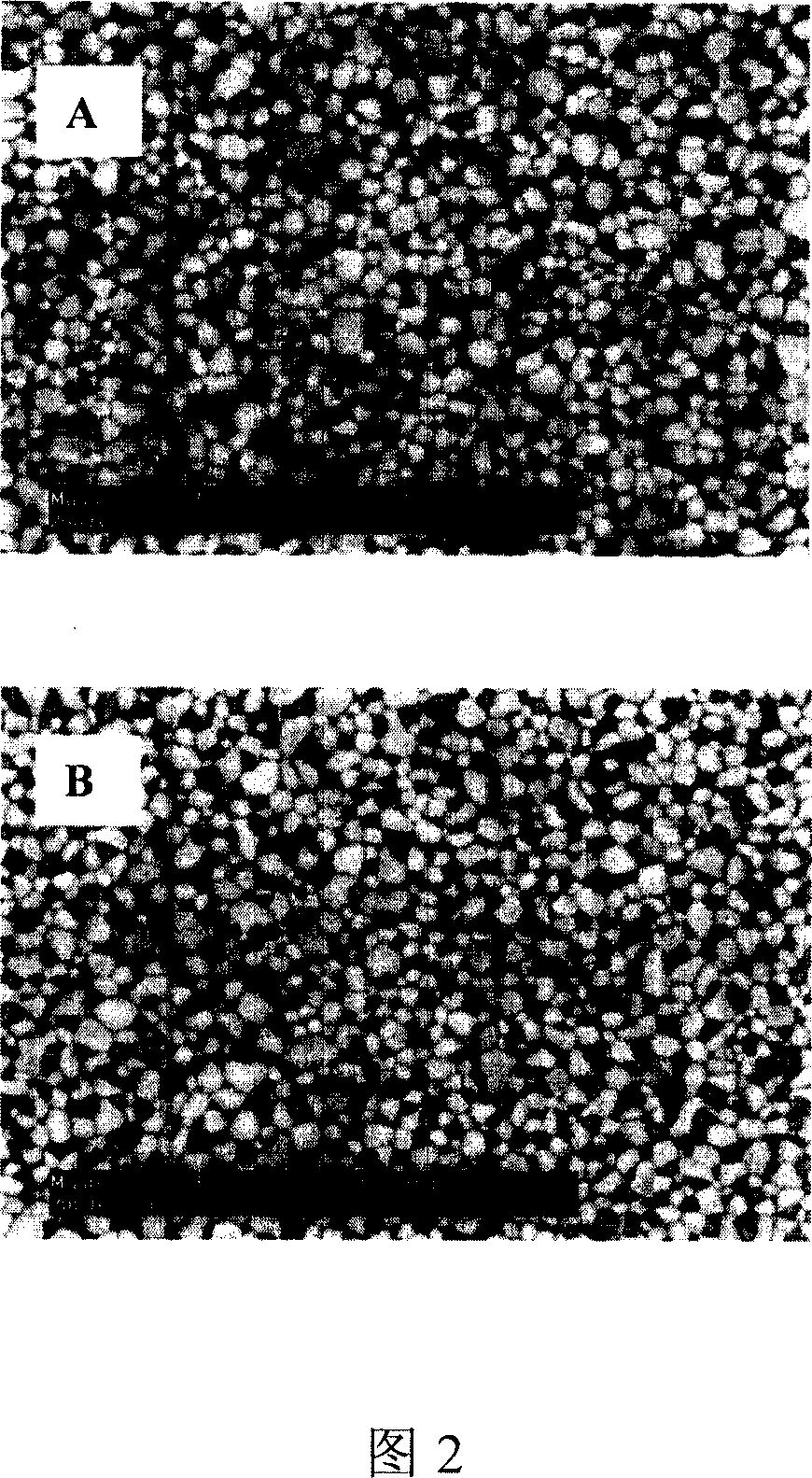

[0072] Synthesis of (100-x) wt% Ce by direct mixing of all metal ion nitrates 0.95 Gd 0.05 o 1.9 -x wt%Gd 0.2 Sr 0.8 FeO 3 Composite film, where 20≤x≤80. According to the desired relative mass ratio of the two oxides, stoichiometric doses of all metal ions (Ce 3+ 、Gd 3+ 、Sr 2+ , Fe 3+ ) nitrate and a beaker, to which an appropriate amount of EDTA and citric acid are added, that is, the ratio of EDTA and citric acid to the amount of total metal ions is 1:1 and 1:1.5 respectively. Then use NH 3 .H 2 O adjust the pH of the solution to 6.0, heat and stir the solution at a constant temperature of 80°C, and finally obtain a colloid with the continuous evaporation of water, pretreat the colloid at 400°C for preliminary decomposition, and calcinate the primary powder at 900°C After 5 hours, the composite oxide powder obtained by the mixed solution method was obtained. The powder is compressed into tablets at 200-400 MPa. The pressed green sheet is sintered at 1400°C for 3...

Embodiment 2

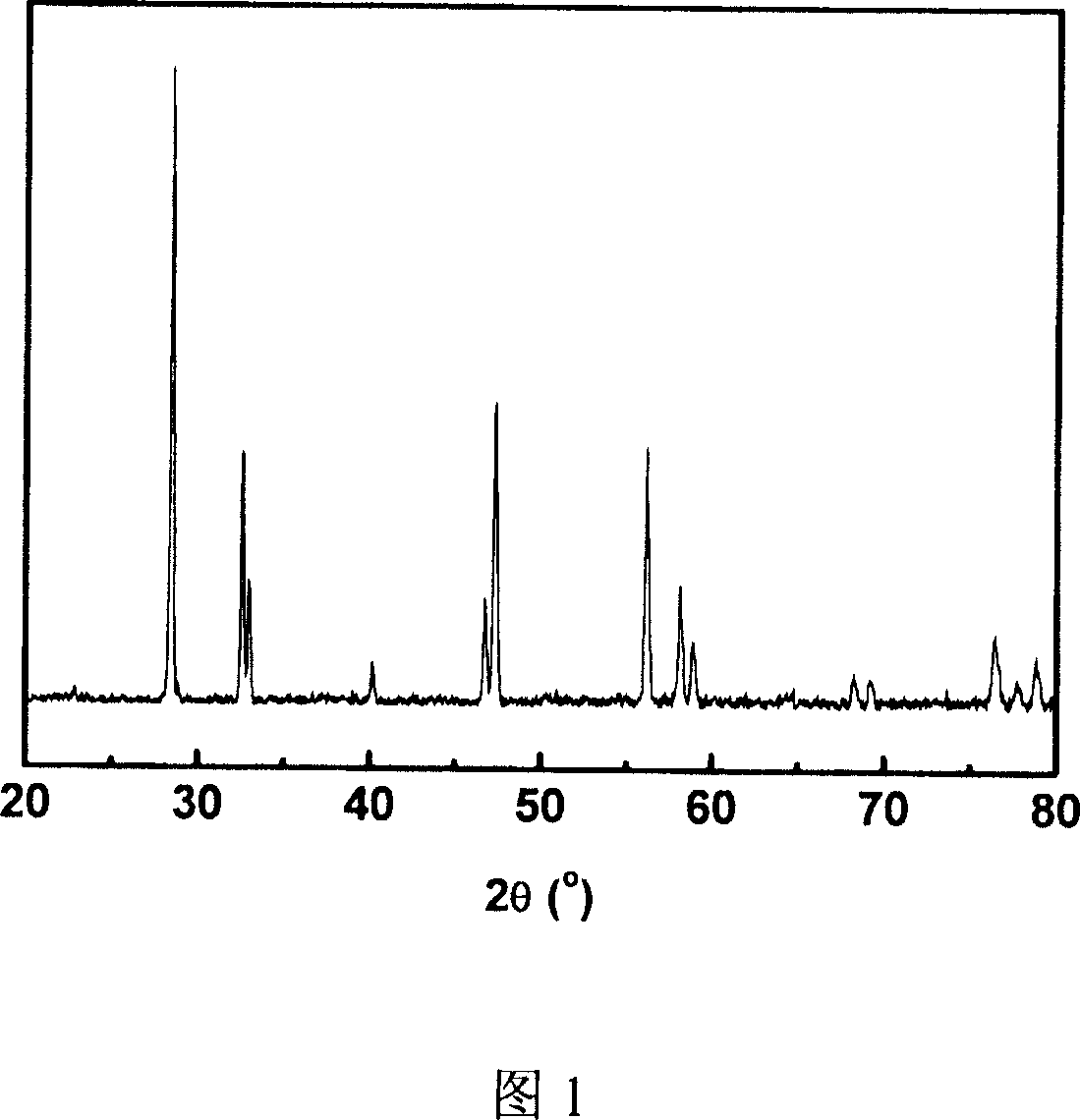

[0074] Synthesis of (100-x)wt%Ce by directly mixing two oxides 0.8 Gd 0.2 o 1.9 -xwt%Gd 0.2 Sr 0.8 FeO 3 Composite film, where 20≤x≤80. Synthesis of Fast Oxygen Ion Conductor GDC and Mixed Conductor Gd by EDTA-citric Acid Complexation 0.2 Sr 0.8 FeO 3 . Take chemical dose of metal ion nitrate and beaker, add appropriate amount of EDTA and citric acid therein, that is, the ratio of EDTA and citric acid to total metal ion amount is 1:1 and 1:1.5 respectively. Then use NH 3 .H 2 O adjust the pH of the solution to 6.0, heat and stir the solution at a constant temperature of 80°C, and finally obtain a colloid with the continuous evaporation of water, pretreat the colloid at 400°C for preliminary decomposition, and calcinate the primary powder at 900°C 5h get GDC and Gd 0.2 Sr 0.8 FeO 3 Powder. It was detected as pure phase perovskite by XRD. Then, the two splits are uniformly mixed according to a certain mass ratio, and then compressed into tablets under 200-400 MPa...

Embodiment 3

[0076] Synthesis of (100-x) wt% Ce by direct mixing of all metal ion nitrates 0.75 SM 0.25 o1.875 -xwt%Sm 0.8 Sr 0.2 FeO 3 Composite film, where 20≤x≤80. According to the desired relative mass ratio of the two oxides, stoichiometric doses of all metal ions (Ce 3+ 、Sm 3+ 、Sr 2+ , Fe 3+ ) nitrate and a beaker, to which an appropriate amount of EDTA and citric acid are added, that is, the ratio of EDTA and citric acid to the amount of total metal ions is 1:1 and 1:1.5 respectively. Then use NH 3 .H 2 O adjust the pH of the solution to 6.0, heat and stir the solution at a constant temperature of 80°C, and finally obtain a colloid with the continuous evaporation of water, pretreat the colloid at 400°C for preliminary decomposition, and calcinate the primary powder at 900°C After 5 hours, the composite oxide powder obtained by the mixed solution method was obtained. The powder is compressed into tablets at 200-400 MPa. The pressed green sheet is sintered at 1400°C for 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Oxygen permeability | aaaaa | aaaaa |

| Oxygen permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com