Method for producing rongalite with low zinc

A production method and a technology for carving white blocks, which are applied in chemical instruments and methods, alkali metal sulfites/sulfites, inorganic chemistry, etc., can solve problems such as the inability to meet sodium bisulfite formaldehyde, etc., and achieve improved economic benefits and efficiency. Social benefits, low manufacturing cost, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

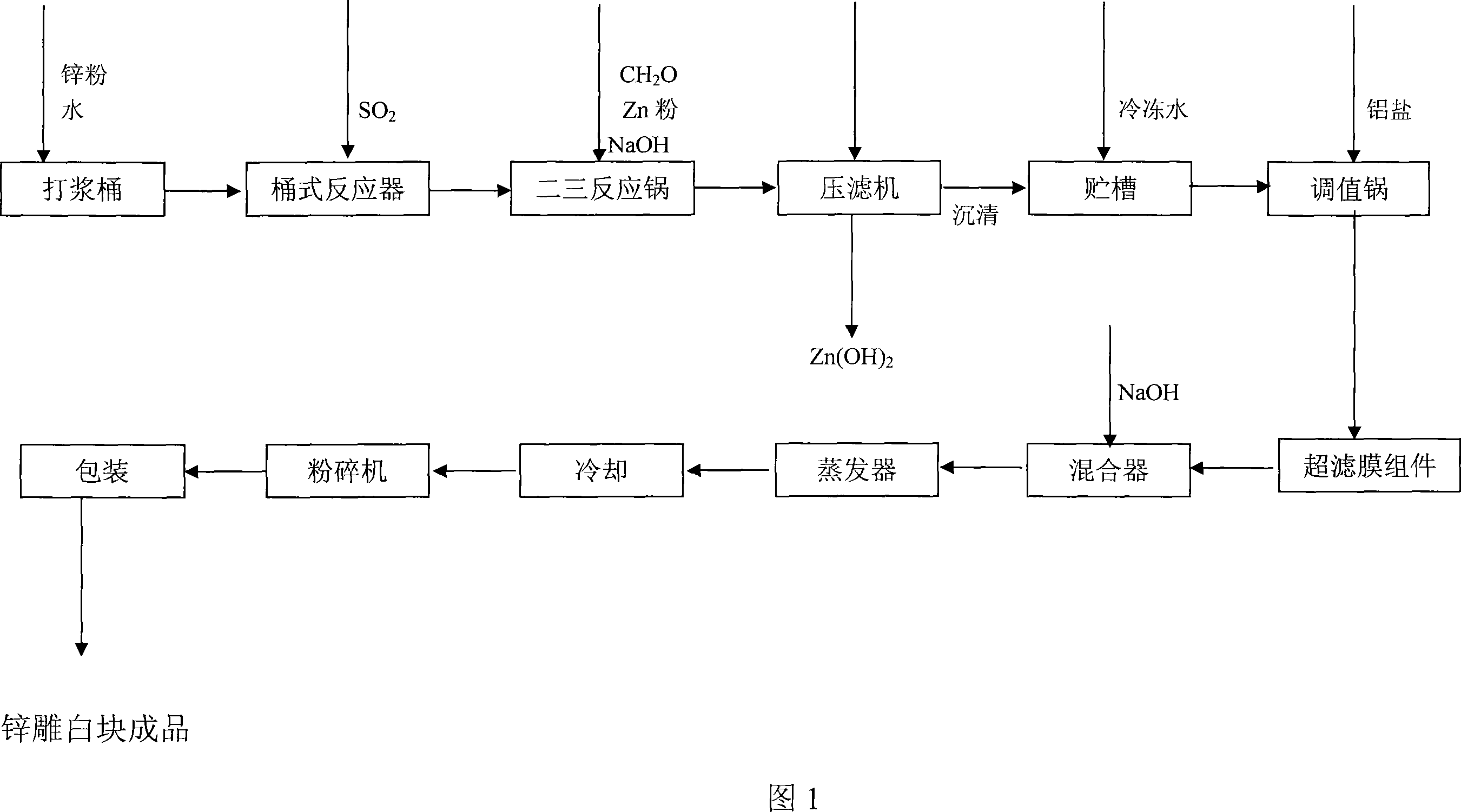

Image

Examples

Embodiment 1

[0022] The component ratio of the low-zinc carved white block of the present invention is by weight percentage:

[0023] The production method of the low-zinc carved white block of the present invention adopts the following process steps:

[0024] 1. First put 30% water and 7% zinc powder on 1.6m 3 In the beating barrel, mix and beat at room temperature, and then put it into the 6m 3 In the barrel reactor, 13% sulfur dioxide gas is added, and the reaction is carried out at a temperature of 30° C. to form zinc dithionite. The reaction time is 120 minutes; the pressure is normal pressure.

[0025] 2. Put zinc dithionite into 10m 3 Add 14% formaldehyde and 5% zinc powder into the two-three reaction pot, and react at 95°C to form basic zinc formaldehyde sulfoxylate, reaction time: 75 minutes; pressure: normal pressure.

[0026] 3. Put 10m 3 The basic zinc hydrogen sulfoxylate formaldehyde in the two or three reaction pots is precipitated, the supernatant is removed, and 22% so...

Embodiment 2

[0034] The component ratio of the low-zinc carved white block of the present invention is by weight percentage:

[0035] The production method of the low-zinc carved white block of the present invention adopts the following process steps:

[0036] 1. Put 32% water and 6.5% zinc powder on 1.6m 3 In the beating barrel, mix and beat at room temperature, and then put it into the 6m 3 In the barrel reactor, 12.5% sulfur dioxide gas is added, and the reaction is carried out at a temperature of 40° C. to form zinc dithionite. The reaction time is 110 minutes; the pressure is normal pressure.

[0037] 2. Put zinc dithionite into 10m 3 Add 15% formaldehyde and 5.5% zinc powder into the two-three reaction pot, and react at 100°C to form basic zinc formaldehyde sulfoxylate, reaction time: 68 minutes; pressure: normal pressure.

[0038] 3. Put 10m 3 The basic zinc hydrogen sulfoxylate formaldehyde in the two or three reaction pots is precipitated, the supernatant is removed, and 21%...

Embodiment 3

[0046] The component ratio of the low-zinc carved white block of the present invention is by weight percentage:

[0047] The production method of the low-zinc carved white block of the present invention adopts the following process steps:

[0048] 1. First put 34% water and 6% zinc powder on 1.6m 3 In the beating barrel, mix and beat at room temperature, and then put it into the 6m 3 In the barrel reactor, add 12% sulfur dioxide gas, and react to zinc dithionite at a temperature of 50° C., reaction time: 100 minutes; pressure: normal pressure.

[0049] 2. Put zinc dithionite into 10m 3Add 16% formaldehyde and 5% zinc powder into the two-three reaction pot, and react at 105°C to form basic zinc formaldehyde sulfoxylate, reaction time: 60 minutes; pressure: normal pressure.

[0050] 3. Put 10m 3 The basic zinc hydrogen sulfoxylate formaldehyde in the two or three reaction pots is precipitated, the supernatant is removed, and 20% sodium hydroxide is added to react again, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com