Nano composite material of flame retardant epoxy resin made from salt of phosphate bi melamine

The technology of double melamine salt and nanocomposite is applied in the field of flame retardant epoxy resin material, which can solve problems such as poor flame retardant performance or poor mechanical performance, and achieve the effects of good flame retardancy, environmental friendliness and small addition amount.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

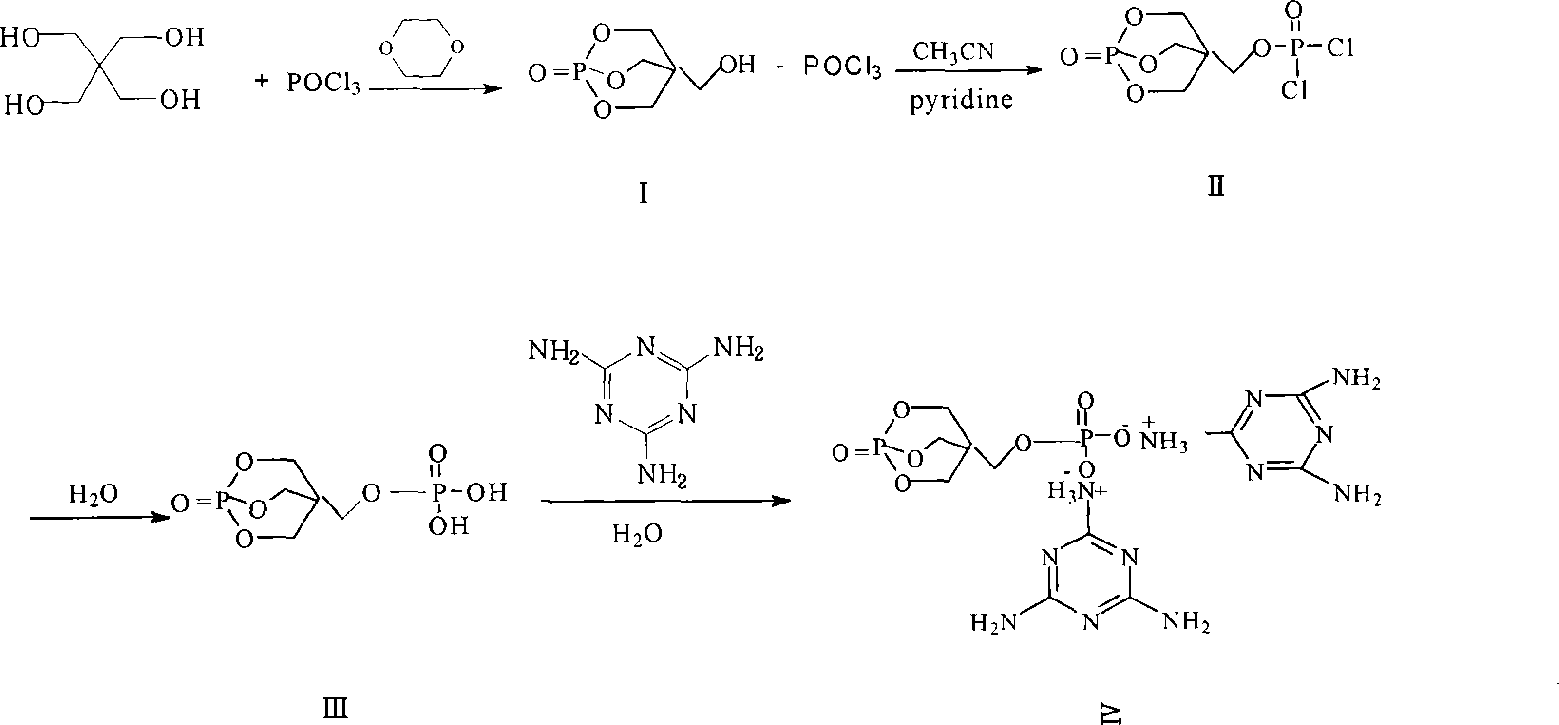

[0044] In a 500mL three-neck flask, add 15.3mL (0.167mol) POCl 3 , 30g (0.167mol) PEPA, 220mLCH 3 CN, stirred under the protection of nitrogen, and heated until the solids were completely dissolved. Add 12 mL of pyridine dropwise within 5 min, and react for 4 h until the raw material completely disappears. Distillation to remove CH 3 CN, a yellow viscous liquid substance II was obtained. Add 180mL of deionized water, stir for 5h, precipitate a white solid, filter and dry to obtain about 30g, the yield is 70%, and the melting point is about 170°C, which is (1-oxo-4-methylene-2,6,7-tri Oxy-1-phosphabicyclo[2.2.2]octane)phosphate (III).

[0045] In a 500ml three-necked flask, add 22.5g (0.178mol) of melamine and 300ml of deionized water, stir, and heat to reflux. Add 13g (0.050mol) III, reflux for 2h, then add 8.5g (0.033mol) III, reflux for 7h, cool, and precipitate a white solid, filter and dry to obtain 35g of flame retardant (IV), with a yield of 80%. The melting point ...

Embodiment 2

[0047] The amount of raw materials and the operation method are the same as Example 1, the esterification reaction is 7h, III 32g, and the yield is 75%; the salinization reaction is 4h after the first III input; the second III input after the reaction 10h, phosphate bismelamine salt IV 37g , the yield was 85%.

Embodiment 3

[0049] Each stage operation method is identical with embodiment 1. POCl 3 The amount added was 20 mL, and after 4 h of esterification reaction, III was 36 g, and the yield was 83%. At the same time, the first input amount of III was 18 g, and the second input amount was 12 g after 2 hours of reaction. The salinization reaction obtained 40 g of phosphate ester bismelamine salt, and the yield was 92%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com