Multiple step type battery control system in use for hybrid powered car

A hybrid vehicle, battery control technology, applied in electric vehicles, transmission systems, digital transmission systems, etc., can solve the problems of increasing control chip load, consumption, difficult to locate and search, and achieve the effect of reducing wiring harnesses and reducing workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

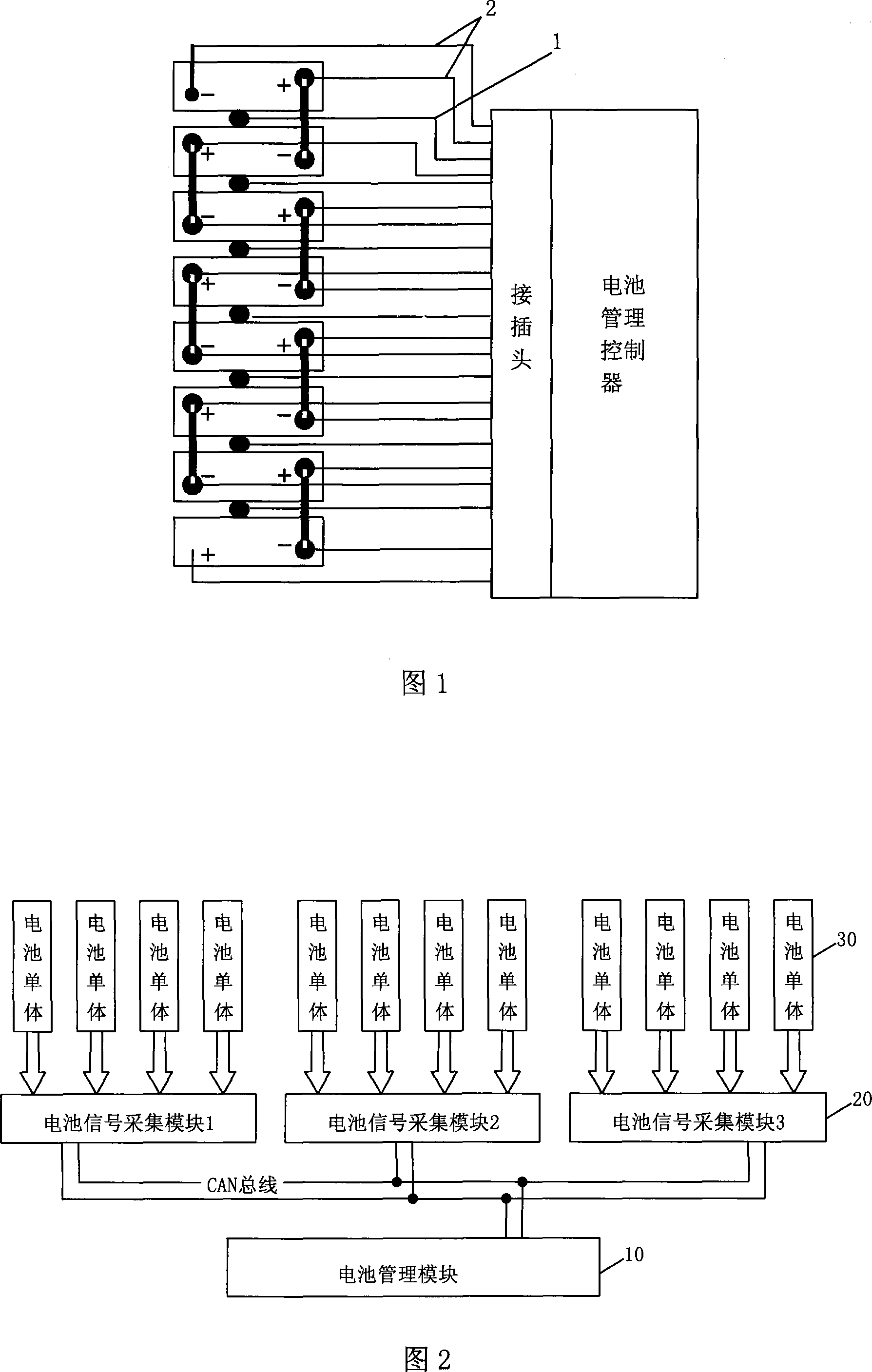

[0014] As shown in Figure 2, the distributed battery control system designed by the present invention consists of a battery control module 10 and several battery signal acquisition modules 20. The battery control module 10 can be regarded as the interface between the battery body and the vehicle controller, and has Functions such as controlling battery charging and discharging, monitoring battery status, and communicating with the vehicle controller. The battery signal acquisition module 20 implements the acquisition and data processing of the voltage and temperature signals of the battery cells 30 , and sends the processed data to the battery control module 10 .

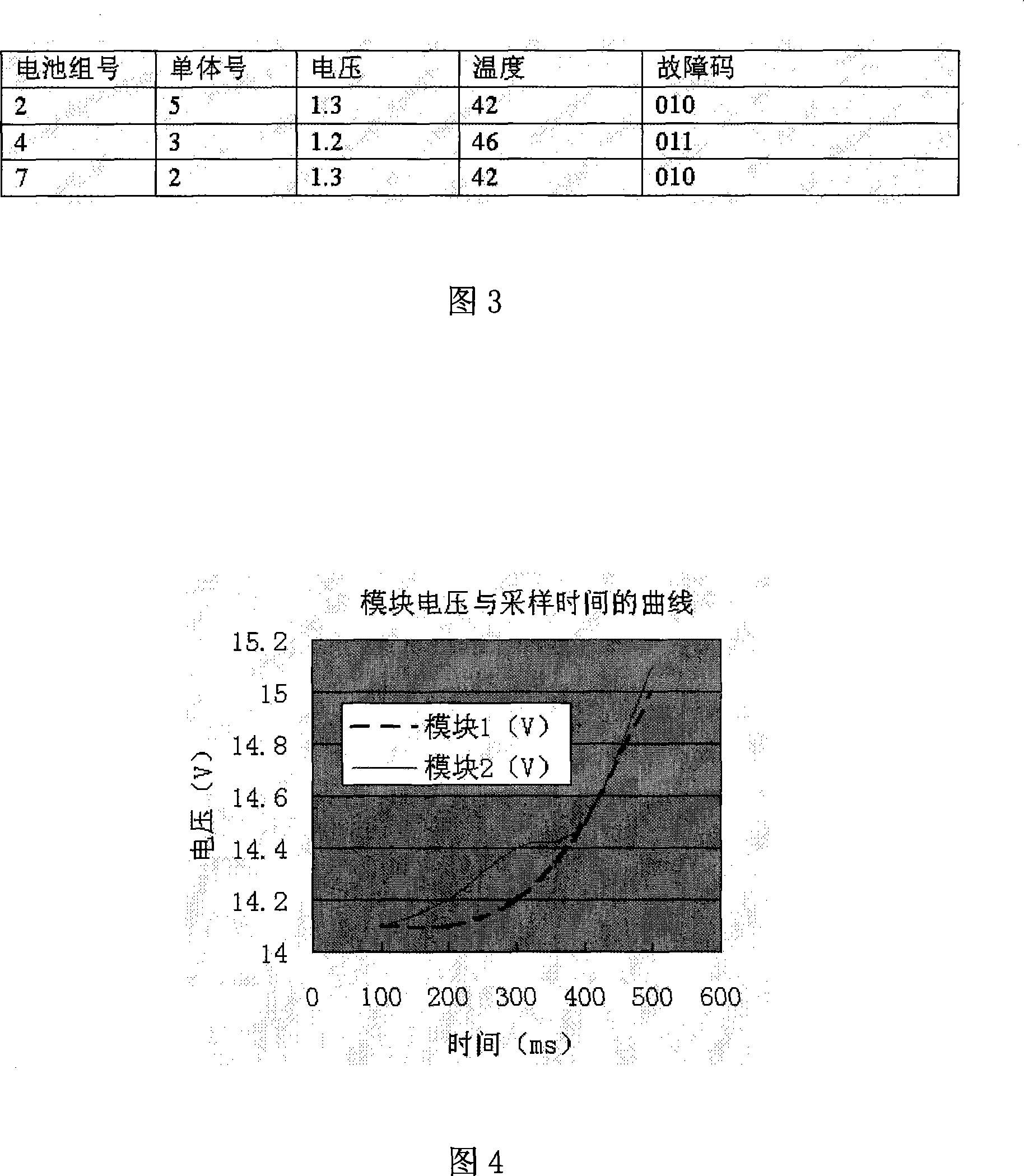

[0015] The battery control system needs to collect relevant signals such as the voltage of the single battery, the temperature of the battery pack, the bus voltage, the bus current, and the inlet and outlet temperatures of the air duct.

[0016] The battery control module 10 in the present invention implements high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com