Biomass hydrogen energy electric generation method

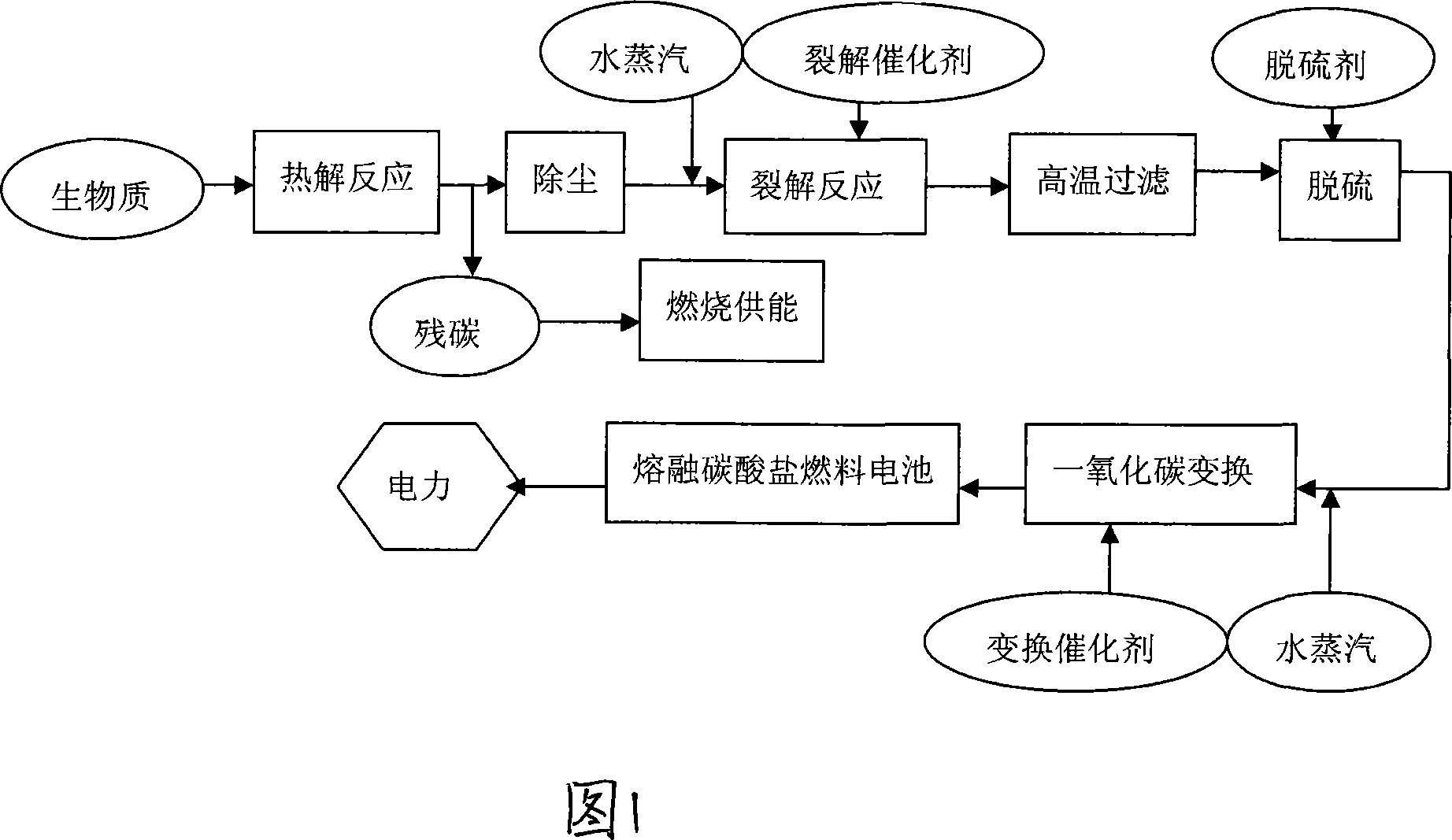

A technology of biomass and biomass raw materials, which is applied in the direction of molten electrolyte fuel cells, circuits, fuel cells, etc., can solve the problems of long microbial conversion cycle, low utilization rate of biomass raw materials, and limitations, so as to improve the economy of energy utilization, Easy to arrange and avoid the effect of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

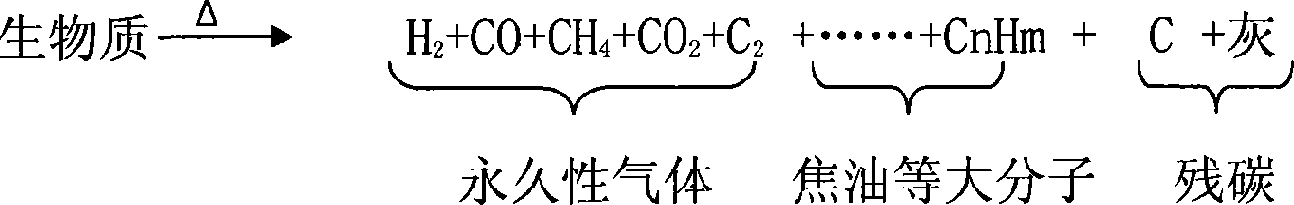

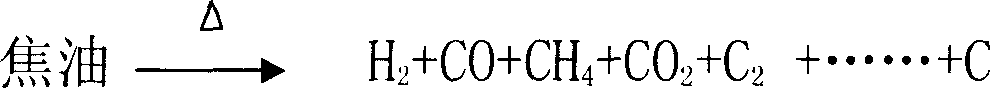

[0010] The biomass raw materials such as straws with a moisture content of 10-20% are subjected to crushing pretreatment and quantitatively sent to the pyrolysis reactor. The pyrolysis reaction of biomass raw materials under the isolation of air occurs during the transportation process in the pyrolyzer. The pyrolysis temperature is 550-650℃, and the pyrolysis reaction time is at least 5 minutes. By monitoring the temperature and adjusting the flue gas heating device accordingly The load realizes the regulation of the pyrolysis reaction temperature. After pyrolysis, biomass raw materials are transformed into gas and solid phase products. The gas phase pyrolysis products include hydrogen, carbon monoxide, carbon dioxide, methane and other non-condensable gases at room temperature and tar and other macromolecular hydrocarbons that condense into liquid at room temperature. The basic reaction of pyrolysis is:

[0011]

[0012] At the rear of the pyrolyzer, pyrolysis solid phase produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com