Method for preparing ammonium carbonate solution from recovered ammonia

An ammonium carbonate and solution technology, applied in chemical instruments and methods, ammonium carbonate/acid carbonate, degassed water/sewage treatment, etc., can solve the problem of low economic benefits, environmental pollution of waste water, waste gas and waste water Many problems, to achieve the effect of low processing cost, recycling, and eliminating environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

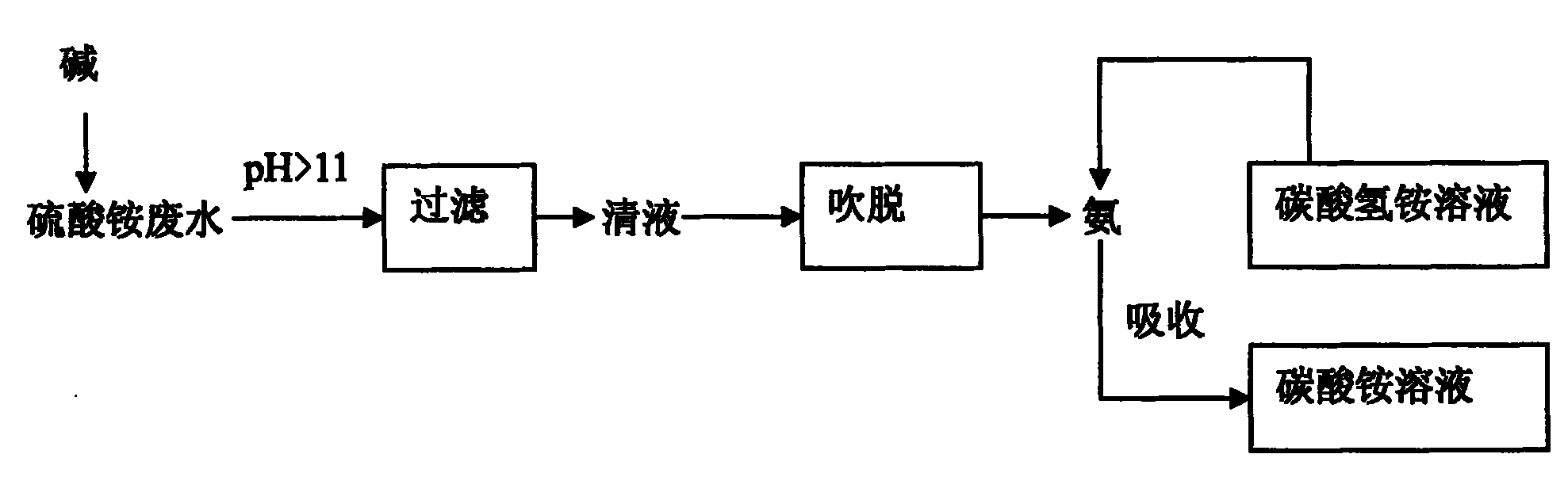

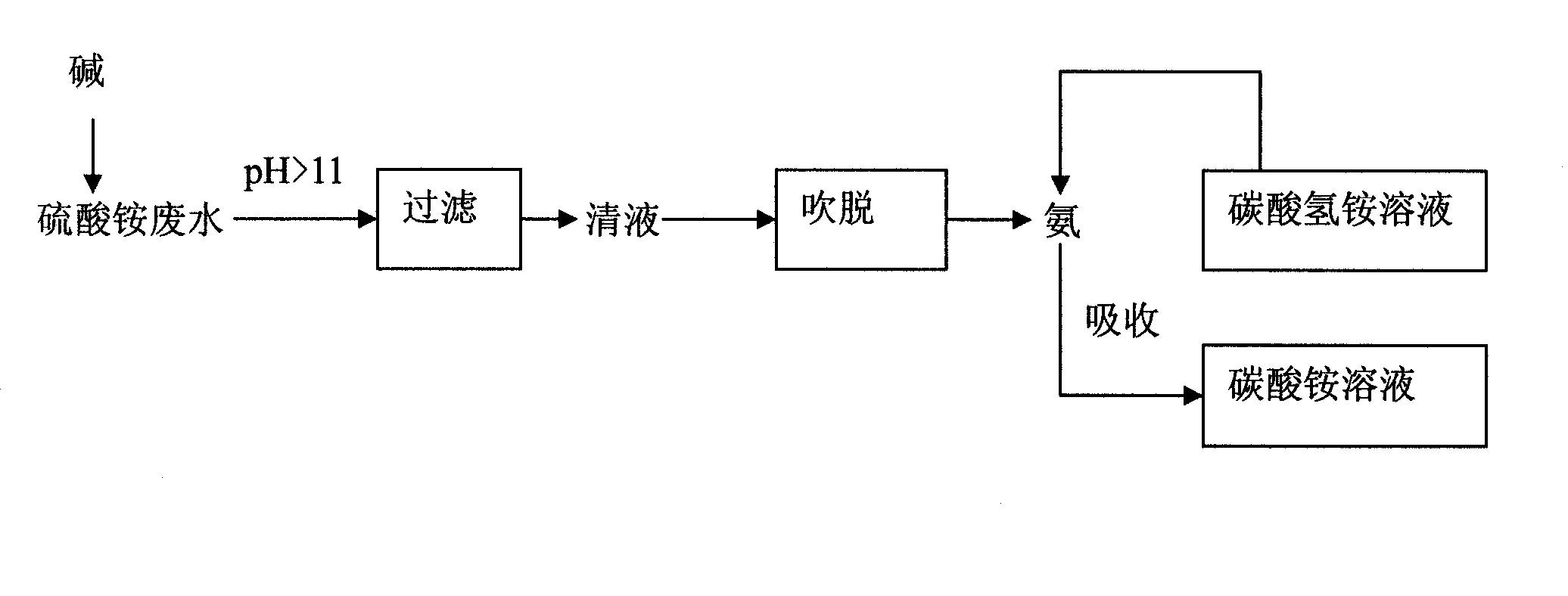

[0014] Example 1: The ammonium sulfate wastewater produced during the production of manganese carbonate was added with alkali to adjust the pH to 11-14, filtered after reacting for 1 hour, and the supernatant was taken. The clear liquid is blown off to desorb the ammonia therein, and the ammonia is sprayed from top to bottom with a 3% ammonium bicarbonate solution in the absorption tower to prepare a 3.6% ammonium carbonate solution.

Embodiment 2

[0015] Example 2: The ammonium sulfate wastewater produced during the production of manganese carbonate was added with alkali to adjust the pH to 11-14, filtered after reacting for 1 hour, and the supernatant was taken. The clear liquid is blown off to desorb the ammonia therein, and the ammonium bicarbonate solution is sprayed from top to bottom to absorb the ammonia in the absorption tower to prepare a 24% ammonium carbonate solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com