Heat-radiation type package structure and its method for making

A packaging structure and heat dissipation technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the problems of affecting the appearance of the package, increasing the cost, and not being able to greatly improve the production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0111] Referring to FIGS. 5A to 5F , they are schematic diagrams of the first embodiment of the heat dissipation package structure and its manufacturing method of the present invention.

[0112] As shown in FIG. 5A , firstly, the semiconductor chip 41 is placed and electrically connected to the chip carrier 42 , and an interface layer 43 is formed on the surface of the semiconductor chip 41 that is not placed on the chip carrier 42 .

[0113] The chip carrier 42 is, for example, a ball grid array (BGA) substrate or a land grid array (LGA) substrate, and the semiconductor chip 41 is, for example, a flip-chip semiconductor chip, and the flip-chip semiconductor chip passes through a plurality of The conductive bump 410 electrically connects its active surface to the chip carrier 42 .

[0114] The interface layer 43 can be, for example, a polyimide (Polyimide) film (P.I.tape) pasted on the semiconductor chip 41 as a substrate, or an epoxy resin (epoxy) coated on the semiconductor ...

no. 2 example

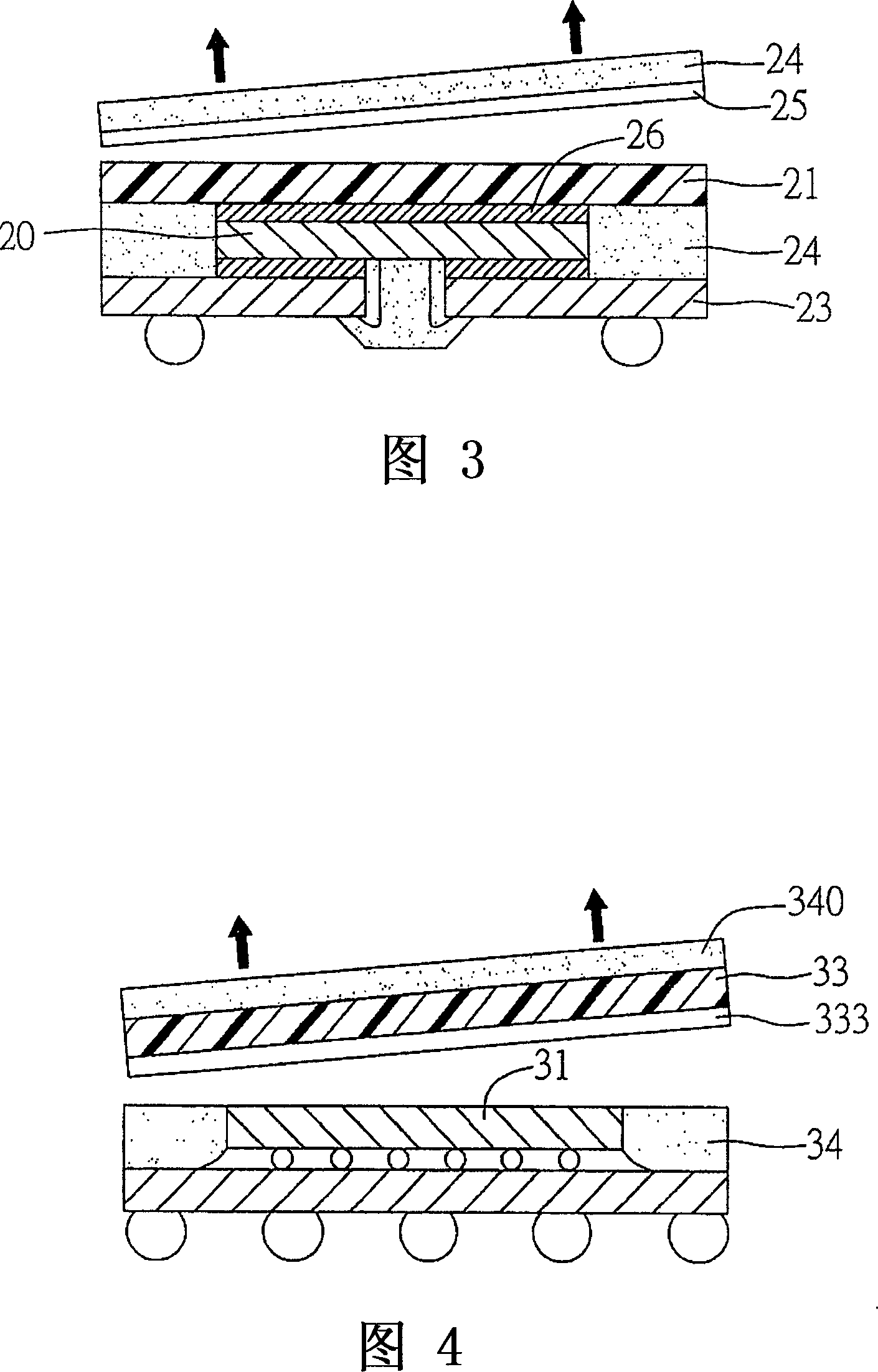

[0121] Referring to FIGS. 6A and 6B , they are schematic diagrams of a second embodiment of the heat dissipation package structure of the present invention. As shown in the figure, the heat-dissipating package structure of this embodiment is substantially the same as that of the preceding embodiments, the main difference being that after removing the interface layer and the encapsulant on the semiconductor chip 51, the encapsulant of the semiconductor chip 51 is also exposed. In the structure, an external heat sink (External Heat Slug) 56 is placed on the surface of the semiconductor chip 51 corresponding to the exposed encapsulant 54, and the external heat sink 56 can be generally planar (as shown in FIG. 6A ) or extended. A plurality of concave-convex structures (as shown in FIG. 6B ) are provided to provide good heat conduction effect of the semiconductor chip 51

no. 3 example

[0123] Referring to FIG. 7 , it is a schematic diagram of a third embodiment of the heat dissipation package structure of the present invention. As shown in the figure, the packaging structure of this embodiment is substantially the same as that of the preceding embodiments, the main difference being that a leaded semiconductor chip 61 is placed on a chip carrier 62, wherein the semiconductor chip 61 is separated from its passive surface. Connected to the chip carrier 62, and electrically connected to the chip carrier 62 through a plurality of bonding wires 67, and a material layer 68 such as a waste chip or a heat sink can be connected to the active surface of the semiconductor chip 61, And an interface layer (not shown) is provided on the material layer 68, so that after the chip carrier 62 is connected with the first heat sink 65 and the encapsulation and molding operation is completed, the cutting operation can be performed and the interface layer and the interface layer ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com