Multifunctional meltblown and filter material and its manufacturing method

A melt-blown filter element, multi-functional technology, applied in chemical instruments and methods, separation methods, filtration and separation, etc., can solve the problem of difficulty in uniform distribution of silver-based nano-antibacterial powder, unstable antibacterial effect, and increased production costs, etc. problems, to achieve the effect of good antibacterial performance, good stability and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Antibacterial, chlorine removal filter

[0023] Get 15KG of CYK-302 inorganic silver-carried antibacterial superfine micropowder (purchasing) with an average particle diameter≤0.5 micron, 84KG of fiber-grade polypropylene pellets produced by Shanghai Jinshan Petrochemical, and 1KG of dispersant, with a twin-screw extruder at 180 Mix and melt granulate at ℃ to make antibacterial base material granules.

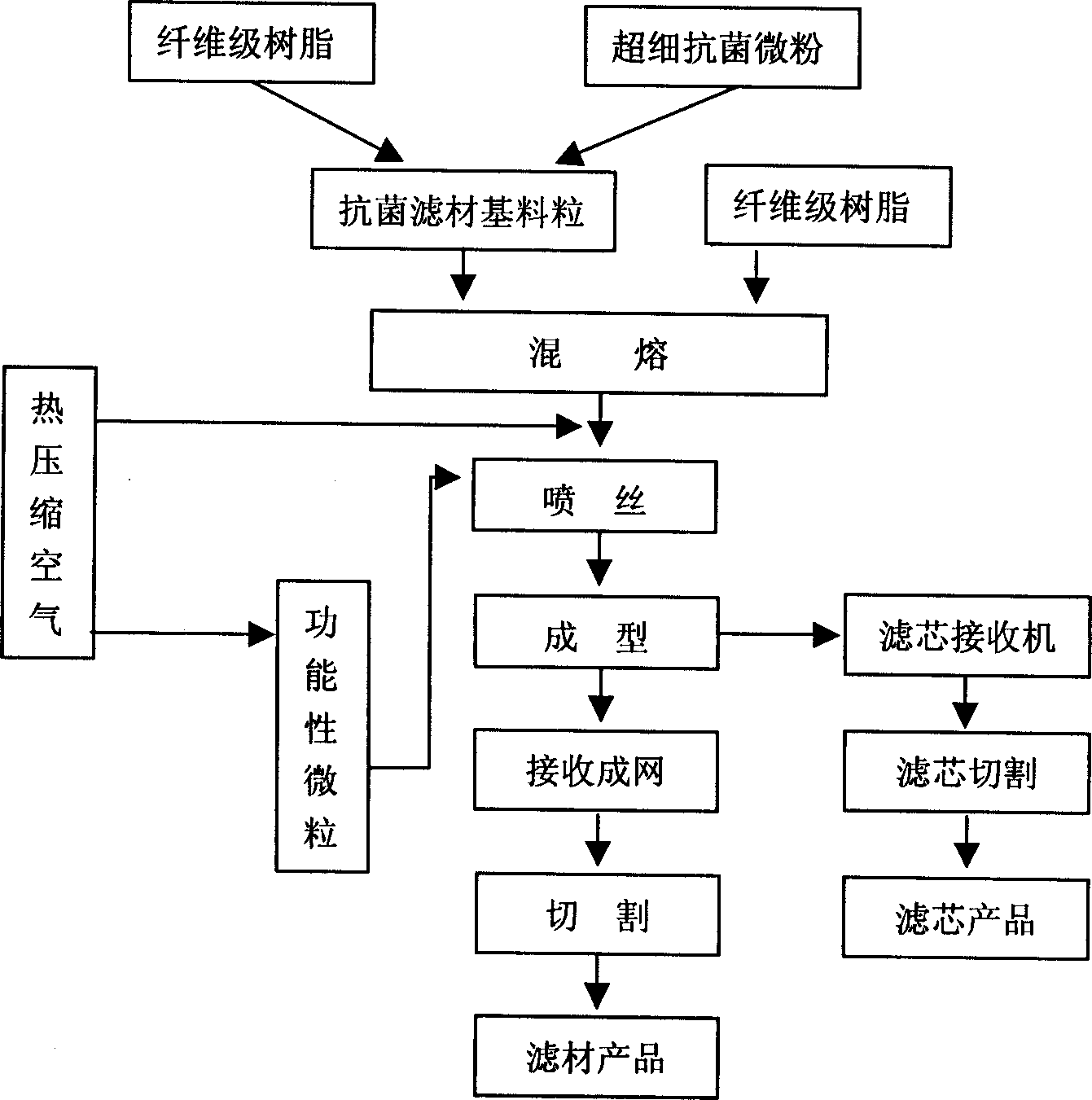

[0024] Take 5KG of the above-mentioned antibacterial base material granules, 95KG of fiber-grade polypropylene, and 10KG of fine calcium sulfite powder containing one crystal water, and pulverize it with a jet mill until the average particle size is ≤0.5 microns, and weigh it according to the process flow in the attached drawing. Good antibacterial base material granules are mixed with fiber-grade resin granules, placed in melt-blown equipment, and fine calcium sulfite powder is loaded into a device with fine holes at the same time; when the antibacterial base material g...

Embodiment 2

[0027] Antibacterial, activated filter

[0028] Take 20KG of CYK-302 inorganic silver-loaded antibacterial ultrafine powder with an average particle size of ≤0.5 microns, and 80KG of fiber-grade polypropylene pellets produced by Shanghai Jinshan Petrochemical Co., Ltd., and use a twin-screw extruder to melt and granulate at 180°C. Antibacterial base pellets.

[0029] Get antibacterial base material granule 5KG, fiber grade polypropylene 95KG, get high-quality anion powder 6KG, pulverize to average particle size and be no more than 0.5 micron, its manufacturing process is the same as embodiment 1, just receive molding with filter element receiver at last, make antibacterial activation filter material. The filtration accuracy of the filter material is 1 micron, and its antibacterial performance is good. After testing by the Shanghai Institute of Industrial Microbiology according to the GB15979-2002 standard, the results show that the antibacterial rate of Escherichia coli is >9...

Embodiment 3

[0031] Adsorption, removal of heavy metal ions, antibacterial filter

[0032] Take 10KG of CYK-302 inorganic silver-loaded antibacterial ultrafine powder with an average particle size of ≤0.5 microns, 89KG of fiber-grade polypropylene pellets produced by Shanghai Jinshan Petrochemical, and 1KG of dispersant, and mix and melt at 180°C with a twin-screw extruder Granulation to make antibacterial base material granules.

[0033] Get antibacterial base-material particle 10KG, fiber-grade polypropylene 90KG, active carbon 4KG, the artificial zeolite 3KG that particle diameter is no more than 0.5 microns, active carbon and zeolite are fully mixed, are placed in special-purpose device, and manufacturing process is identical with embodiment 1, Made into a filter element, the filter element is not only antibacterial, but also has the function of absorbing and removing metal ions such as iron, copper, lead, and zinc.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com