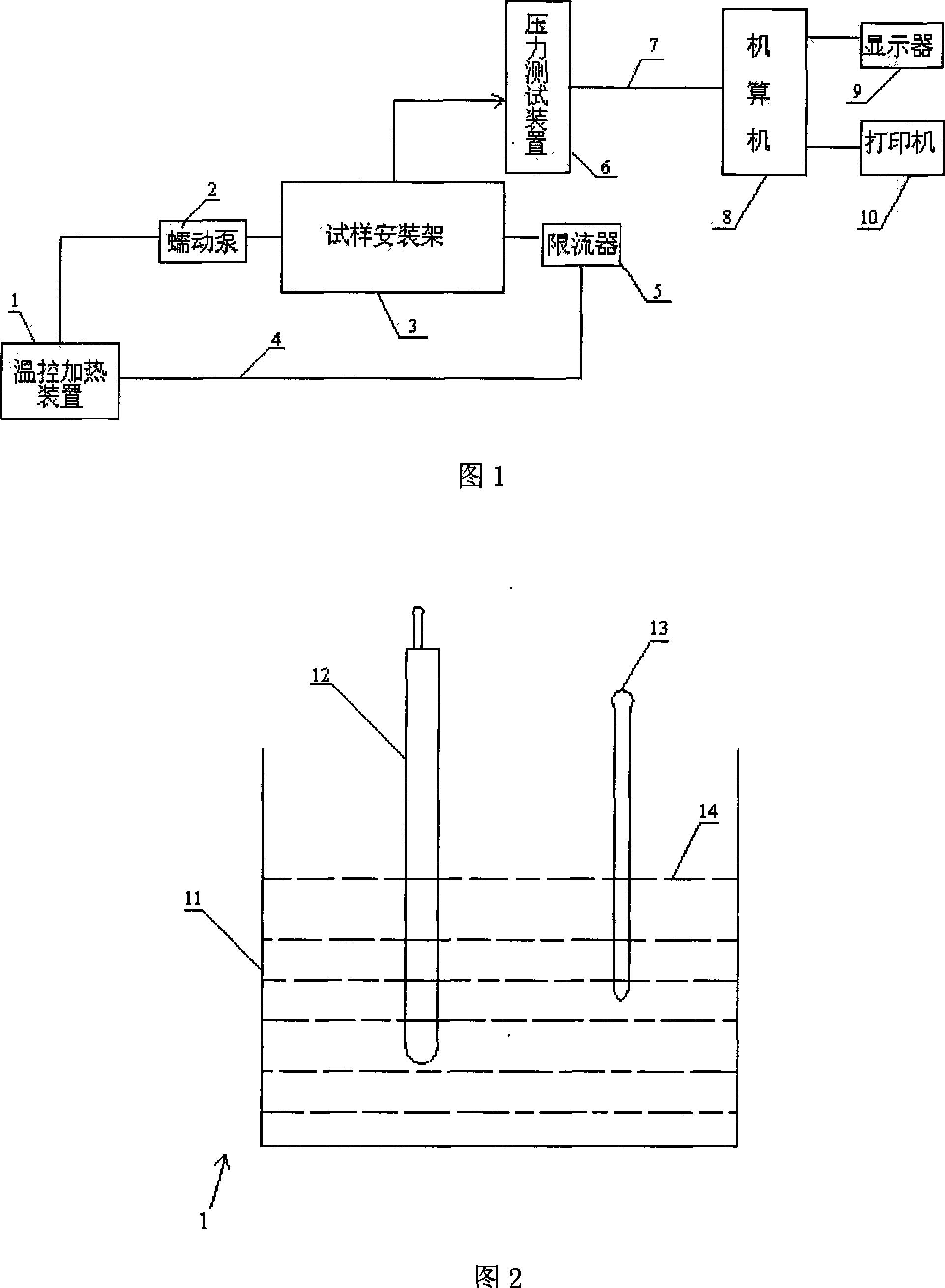

Weave type artificial blood vessel fatigue performance bionic test device and its test method

An artificial blood vessel, fatigue performance technology, applied in the measurement device, the use of repetitive force/pulsation force to test the strength of materials, specific gravity measurement, etc., can solve the problem of lack of complete simulation of the test method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

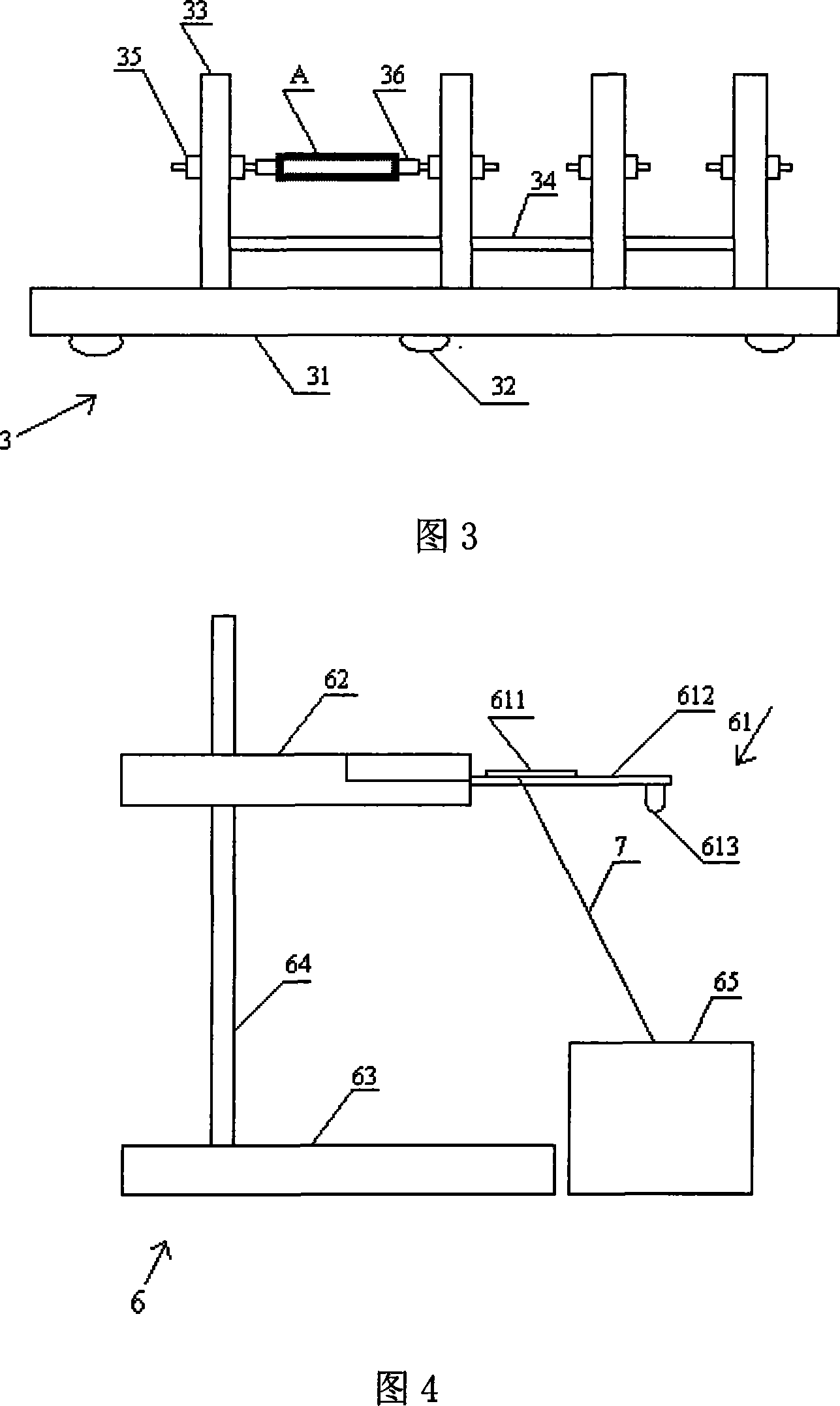

[0051] The specific operation steps of the fatigue performance bionic test on the twill tubular polyester fabric textile artificial blood vessel are as follows:

[0052] [1] Turn on the power supply, turn on the computer 8 and the DC stabilized power supply 65 equipped with processing and conversion signal software, and preheat for half an hour;

[0053] [2] Add two-thirds of its volume of water 14 to the liquid storage tank 11, and then check the entire test system to ensure that the system can circulate and no water leakage occurs. If there is any inappropriateness, it should be adjusted in time to avoid Increase the test error when adjusting in the middle of the test;

[0054] [3] Select a 3-up and 1-down twill tubular polyester fabric with a diameter of 4 mm, a length of 3 cm, and a warp and weft density of 1300 threads / 10 cm as the textile artificial blood vessel sample A, and place it on the elastic rubber tube 36, Then the left end of the elastic rubber tube 36 that is...

Embodiment 2

[0061] The test procedure of its fatigue performance bionic test is the same as that of Example 1, except that (1) the 2 upper and 2 lower reinforced twill tubular fabrics with a diameter of 16mm, a length of 10cm, and a warp and weft density of 1200 / 10cm are respectively As the textile artificial blood vessel sample A, (2) the pulsation frequency of the electronic peristaltic pump 2 is selected as 6Hz, (3) the maximum pressure that the textile artificial blood vessel sample A bears is adjusted to 2000mmHg, (4) the test time is 720 hours (1 month); The warp and weft density of the textile artificial blood vessel sample A obtained at last are 1100×1190 / 10cm, and the changes of warp and weft density are respectively Based on the above results, it is considered that the textile artificial blood vessel sample A cannot be applied clinically.

Embodiment 3

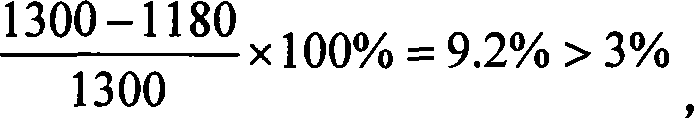

[0063] The test procedure of its bionic test for fatigue performance is the same as that of Example 1, except that (1) the 3 upper and 1 lower twill tubular fabrics with a diameter of 36 mm, a length of 18 cm, and a warp and weft density of 1300 pieces / 10 cm are used as Textile artificial blood vessel sample A, (2) the pulsation frequency of the electronic peristaltic pump 2 is selected as 10Hz, (3) the maximum pressure that the textile artificial blood vessel sample A bears is adjusted to 120mmHg, (4) the test time is 2610 hours ( 3 months); the warp and weft density of the artificial blood vessel sample obtained at last is 1180×1230 / 10cm, and the change of warp density is 1300 - 1180 1300 × 100 % = 9.2 % > 3 % , The variation of weft density is 1300 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com