Method of producing group iii nitride substrate wafers and group iii nitride substrate wafers

A nitride and wafer technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device parts, semiconductor devices, etc., can solve the problems such as no suggestion for III-nitride substrate wafer polishing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

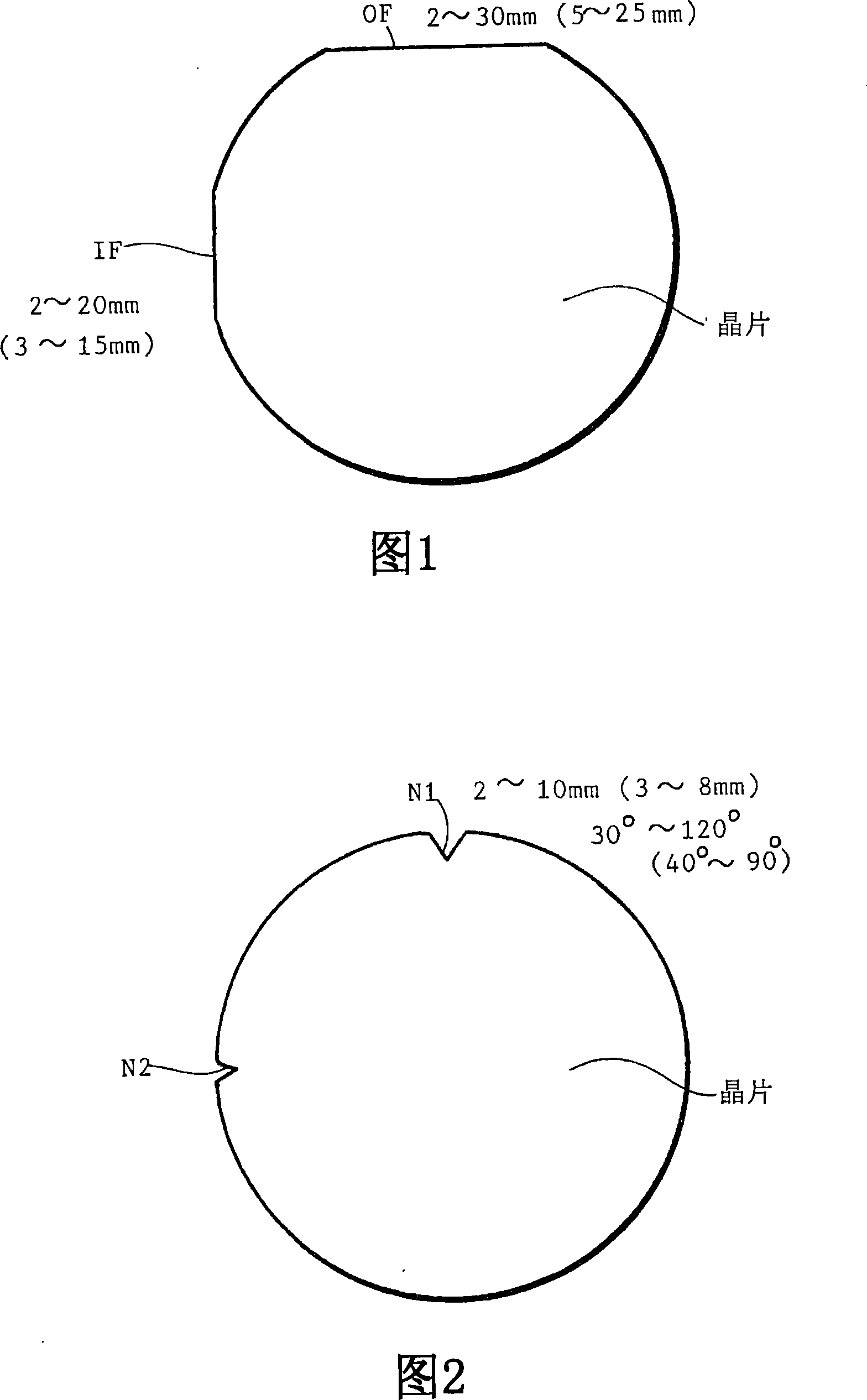

[0094] Aluminum oxide (Al 2 o 3 ) polishing plate of the disc. The ground, ground and polished sample wafers were 50 mm diameter and 0.5 mm thick GaN circular wafers in the HVPE grown state. The GaN ingot in the as-grown state is obtained by growing a GaN crystal on a GaAs lower substrate and removing the GaAs lower substrate. GaN substrate wafers in multiple growth states are fabricated by wire sawing GaN ingots. Each as-grown wafer had a 16 mm long orientation plane (OF). The central angle (Υ) of OF is 18 degrees. The removal width h of OF was 1.6 mm. Each sample is a set of wafers with three growth states of OF.

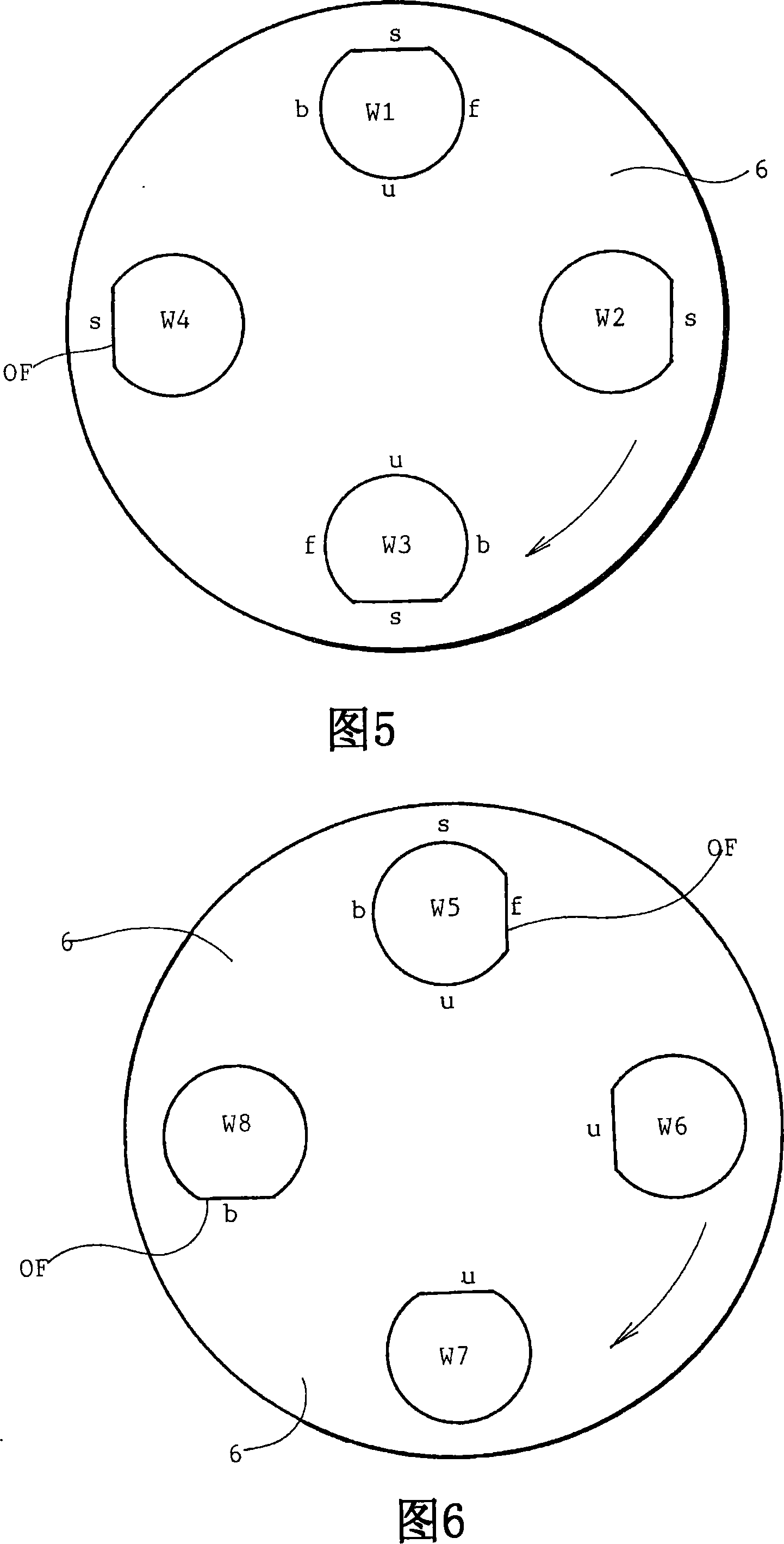

[0095] By heating the polished plate to a temperature of Tm + 30°C, rubbing the bottom of the polished plate with thermoplastic solid wax to soften the wax, placing the wafer in the grown state at a margin p (p = 5 mm) of 5 mm from the edge of the plate and removing the grown state The wafer was pressed to the polishing plate to stick three as-grown GaN waf...

Embodiment 2

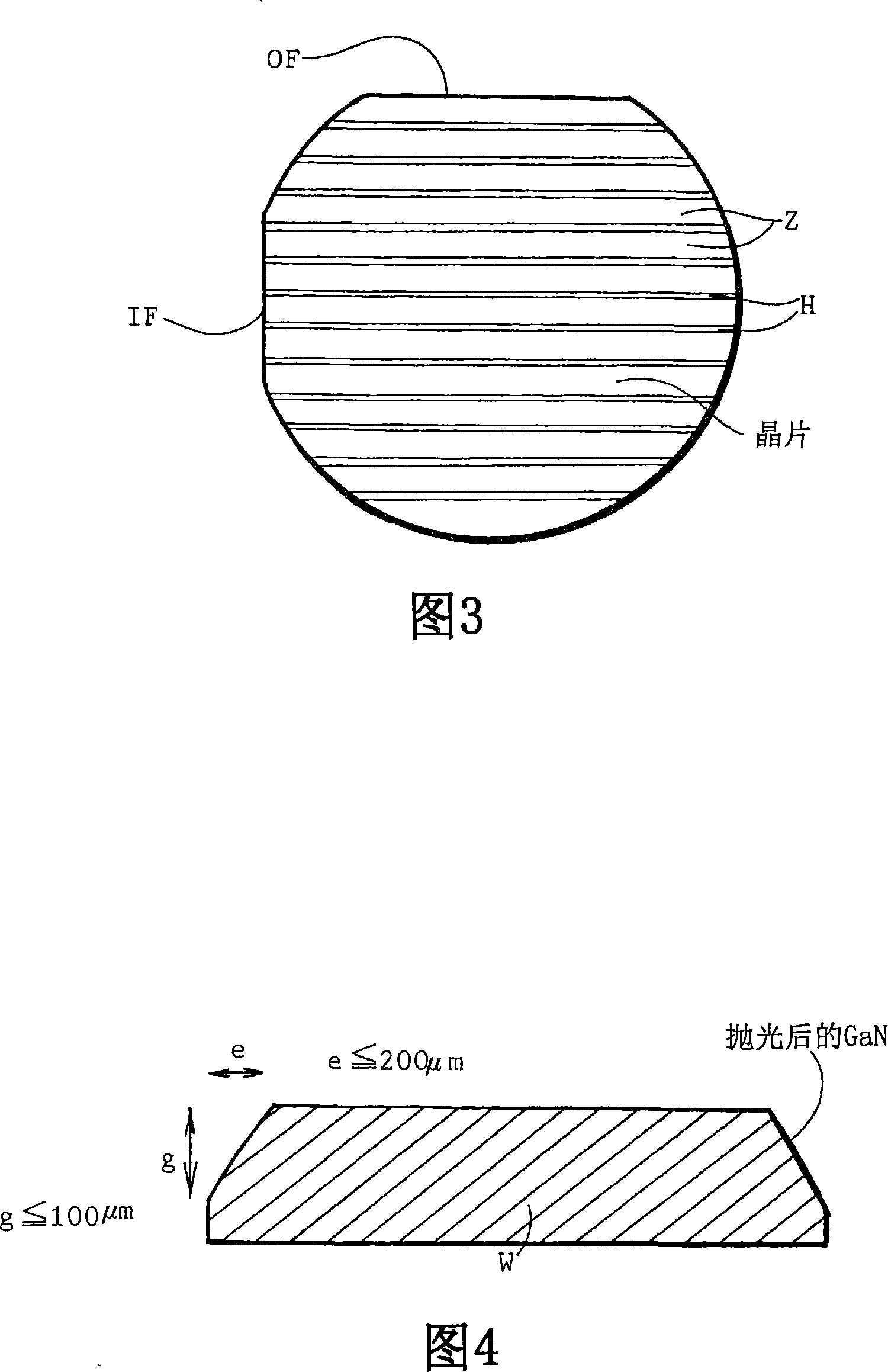

[0123] Embodiment 2 adopts aluminum oxide (Al 2 o 3 ) polishing plate of the disc. The target GaN wafer for the grinding, lapping and polishing processes is a GaN wafer in the HVPE growth state with a multi-group band structure with a diameter of 50 mm and a thickness of 0.5 mm. The banded structure refers to a heterogeneous GaN crystal with alternating groups of parallel low-density single-crystal regions and parallel defect-accumulated regions. It has been prepared by preparing a GaAs lower substrate, fabricating a tape mask on the GaAs lower substrate, growing a GaN film crystal on the tape masked lower substrate by the HVPE method, making a polished surface, and maintaining the polished surface until the end , GaN wafers with ribbon structure were prepared. GaN / GaAs synthesis wafers in the HVPE growth state were prepared. As-grown GaN free-standing wafers were obtained by removing the GaAs underlying substrate and beveling the edges. Alternatively, if a tall GaN cryst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com