Msf distillate driven desalination process and apparatus

A technology for distillate and desalination, applied in the field of MSF distillation, can solve problems such as hindering the operation of reverse osmosis equipment, and achieve the effects of high RO membrane regeneration rate, improved performance and cost-effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The invention significantly improves the MSF desalination process in the prior art. By reading and understanding the foregoing description and the features and principles of the invention illustrated in the accompanying drawings, an experienced artisan who designs, manufactures and operates the water desalination system contemplated by the invention can practice the invention and realize its benefits .

[0045] According to one aspect of the present invention, it is improved in that it has been found that the extract of the MSF distillate can be used to power other process cycles operating at lower temperatures. It has also been found that the extract brings about a significant increase in performance in the MSF desalination plant from which the distillate is extracted. These improvements are not disclosed by the prior art.

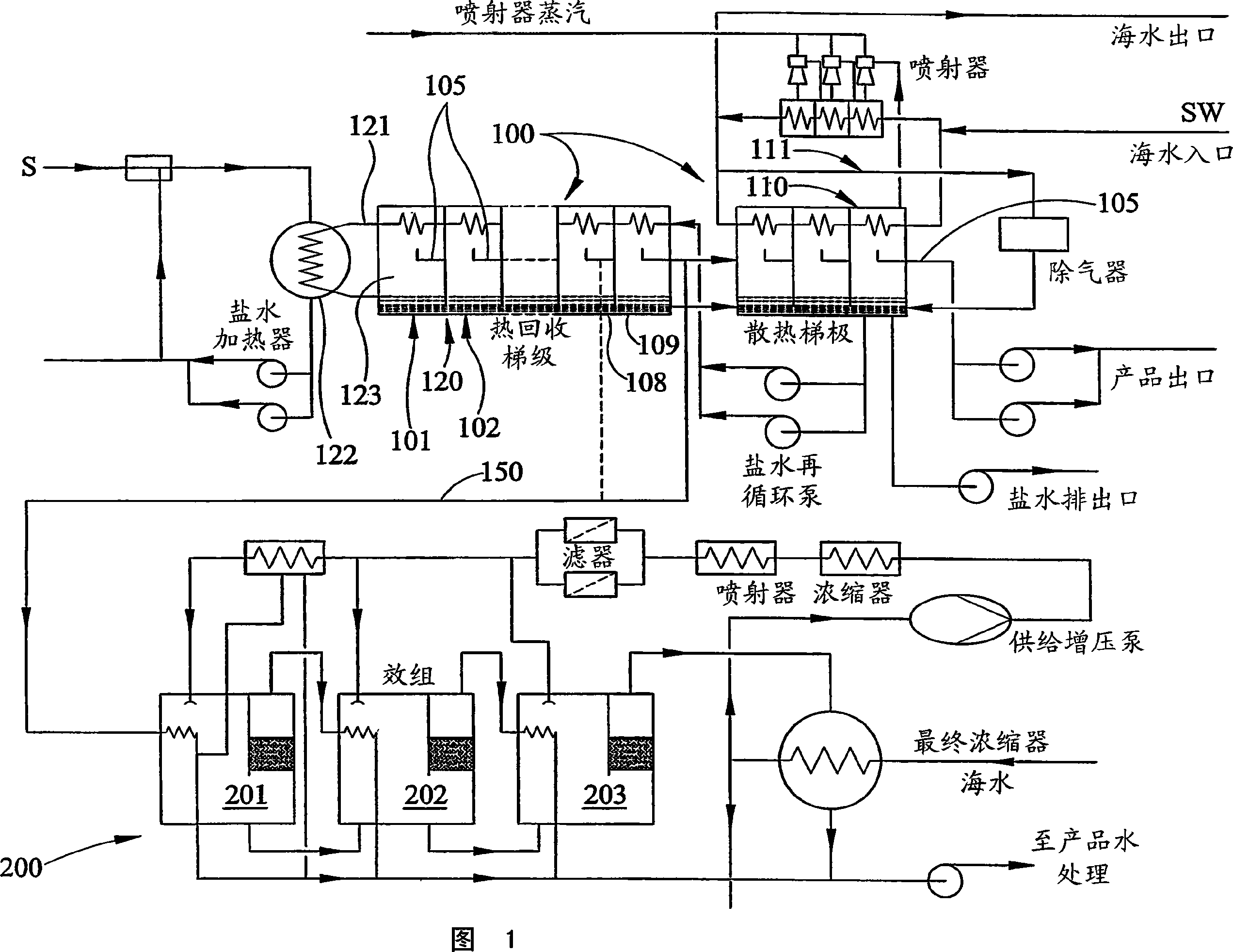

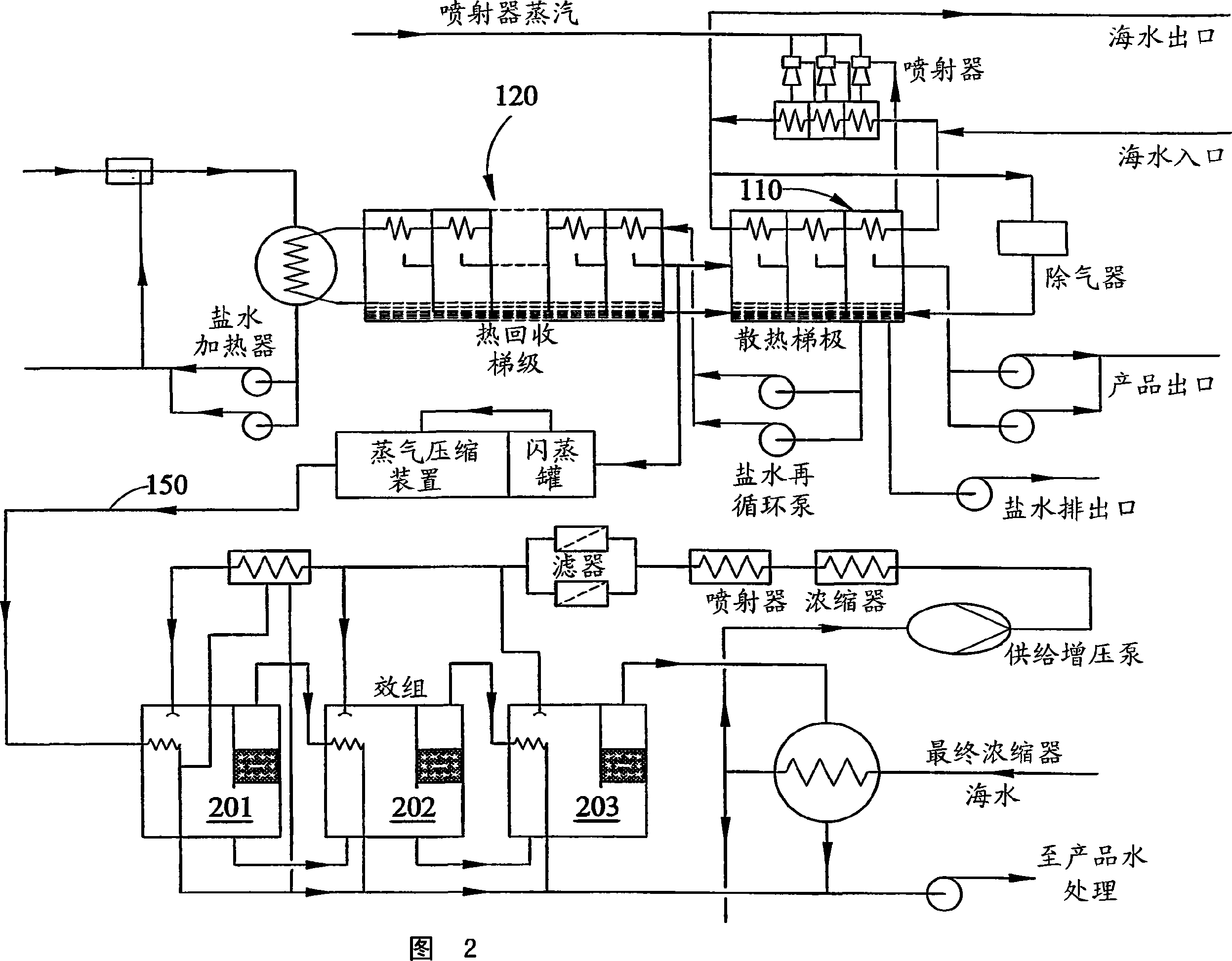

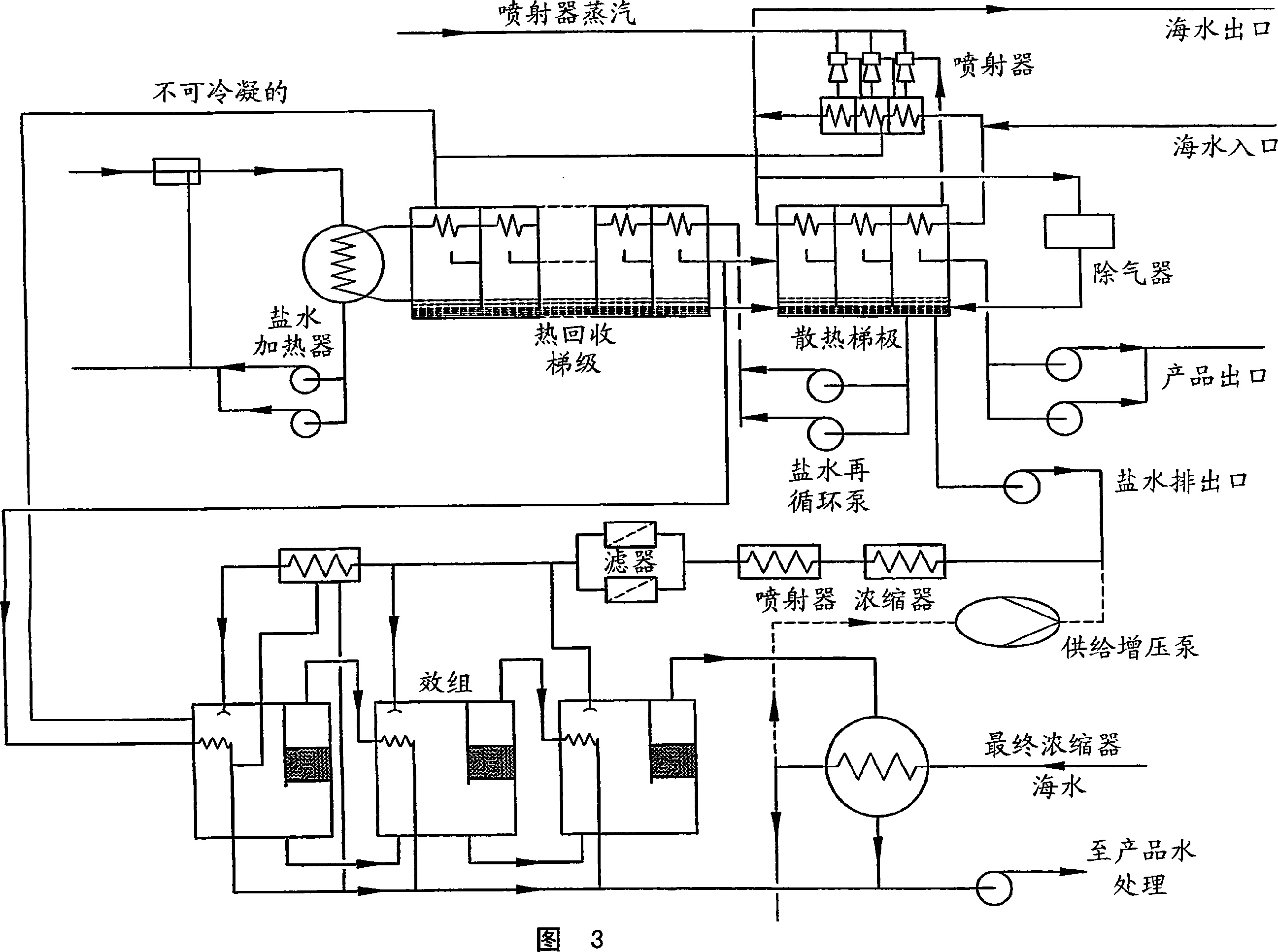

[0046] In each of the embodiments shown in FIGS. 1-4 , the MSF is indicated generally at 100 , which includes a heat dissipation stage 110 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com