Acid-cured environment-friendly binder and preparation method thereof

An environmentally friendly, adhesive technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

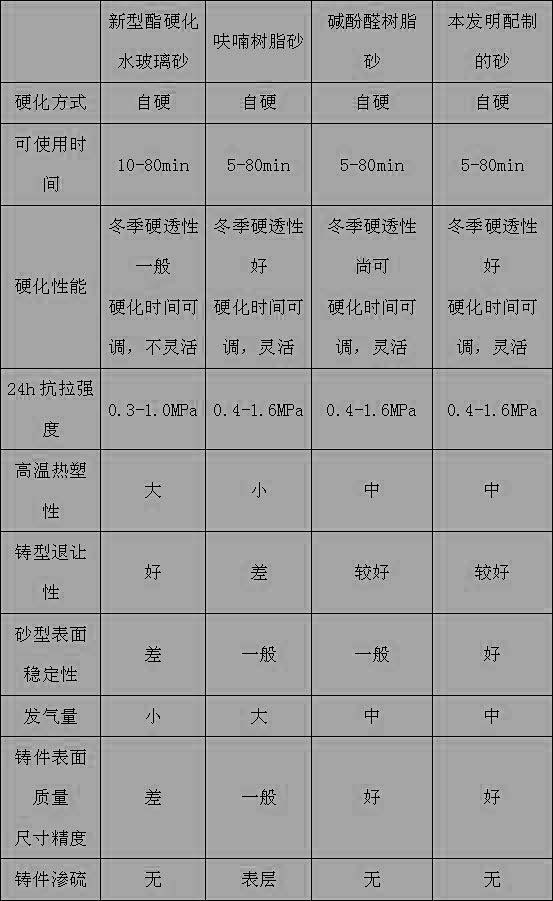

Image

Examples

Embodiment 1

[0021] Firstly, the raw materials were weighed, which contained 60% cardanol, 20% furfuryl alcohol extracted from corncobs, 8% potassium hydroxide, and 12% water.

[0022] Then cardanol is put into the reaction kettle after the moisture and ash content are qualified, and when the temperature is raised to 40°C-60°C, potassium hydroxide is added to catalyze it, and the cardanol self-polymerizes to 8-100,000 MPa·s under alkaline conditions at high temperature; Continue to heat up to 100°C-120°C, keep warm for 0.5-1.5 hours, continue to heat up to 280°C-350°C, keep warm for 1.5-3.5 hours; then lower to 40°C-60°C and adjust the pH value to 4 ~5.5, add furfuryl alcohol, raise the temperature to 80℃~110℃, keep warm for 0.5-1.5 hours; then lower the temperature to 40℃~60℃, add water to adjust the pH value to 6--8, and then adjust the viscosity to prepare Get the product. Subsequently, various characterization tests were carried out on the product, and the results proved to be the des...

Embodiment 2

[0026] Firstly, raw materials were weighed, which contained 50% eugenol, 30% furfuryl alcohol extracted from corncobs, 8% potassium hydroxide, and 12% water.

[0027] After the eugenol is tested to pass the moisture and ash content, put it into the reaction kettle, and add barium hydroxide to catalyze it when the temperature rises to 50°C-60°C. Raise the temperature to 110°C-120°C, keep it warm for 0.5-1 hour, continue to raise the temperature to 290°C-350°C, keep it warm for 1.5-2.5 hours; then lower it to 50°C-60°C and adjust the pH value to 4-5, Add furfuryl alcohol, raise the temperature to 100°C-110°C, keep warm for 0.5-1 hour; then lower the temperature to 50°C-60°C, add water to adjust the pH value to 7-8, and then adjust the viscosity to obtain the product. Subsequently, various characterization tests were carried out on the product, and the results proved to be the desired product.

Embodiment 3

[0029] Firstly, raw materials were weighed, which contained 55% guaiacol, 25% furfuryl alcohol extracted from corncobs, 8% barium hydroxide, and 12% ethanol.

[0030] After the guaiacol is tested for moisture and ash content, it is put into the reaction kettle, and when the temperature rises to 50°C-55°C, barium hydroxide is added to catalyze it, and the guaiacol self-polymerizes at high temperature to 85,000-90,000 MPa under alkaline conditions. s; continue to heat up to 115°C-120°C, keep warm for 1-1.5 hours, continue to heat up to 290°C-330°C, keep warm for 1.5-2 hours; then lower to 50°C-55°C and adjust the pH value to 4.5~5, add furfuryl alcohol, raise the temperature to 115℃~120℃, keep it warm for 1-1.5 hours; then drop the temperature to 50℃~55℃, add ethanol to adjust the pH value to 7.5--8, and then adjust the viscosity to obtain product. Subsequently, various characterization tests were carried out on the product, and the results proved to be the desired product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com