Bio-surfactant polylol manufactured with jatropha curcas oil

A bio-based polyol and jatropha oil technology, applied in the preparation of ester groups and hydroxyl groups, organic chemistry, etc., can solve the problems of poor performance, complicated process, high raw material cost, etc., and achieve high reaction degree, high product conversion rate, The effect of purchasing convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

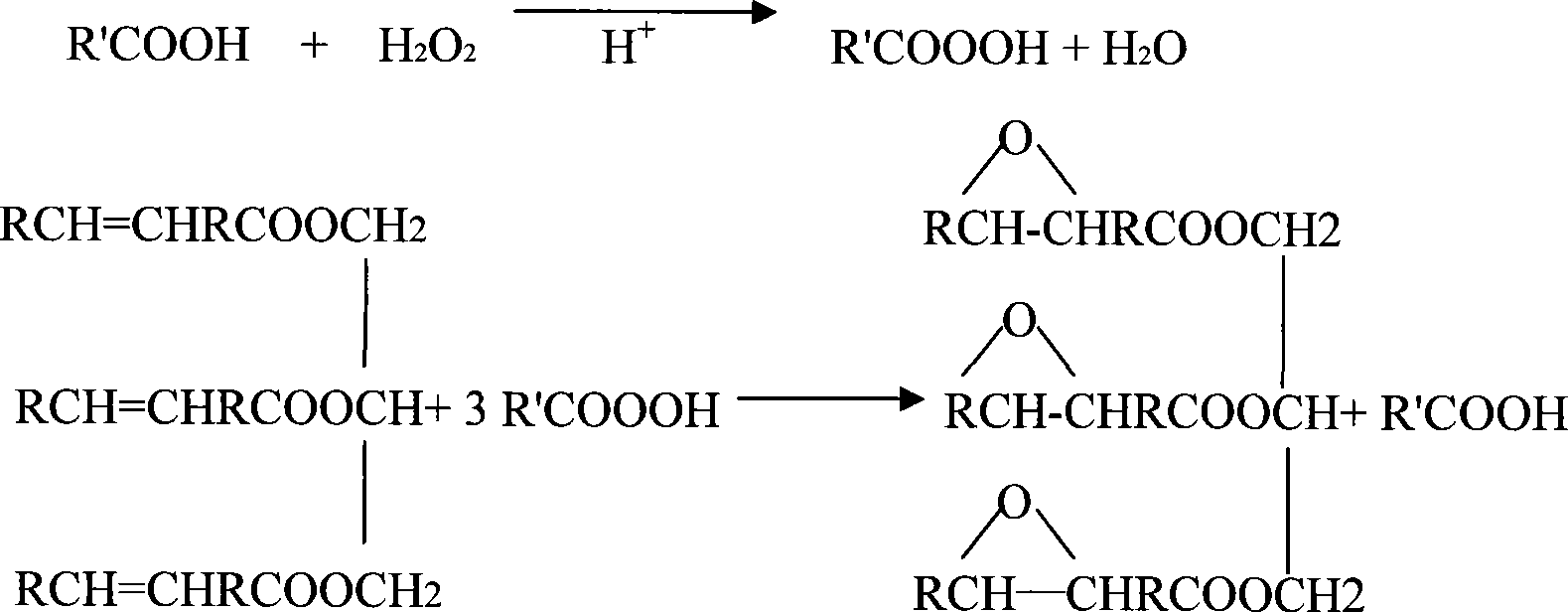

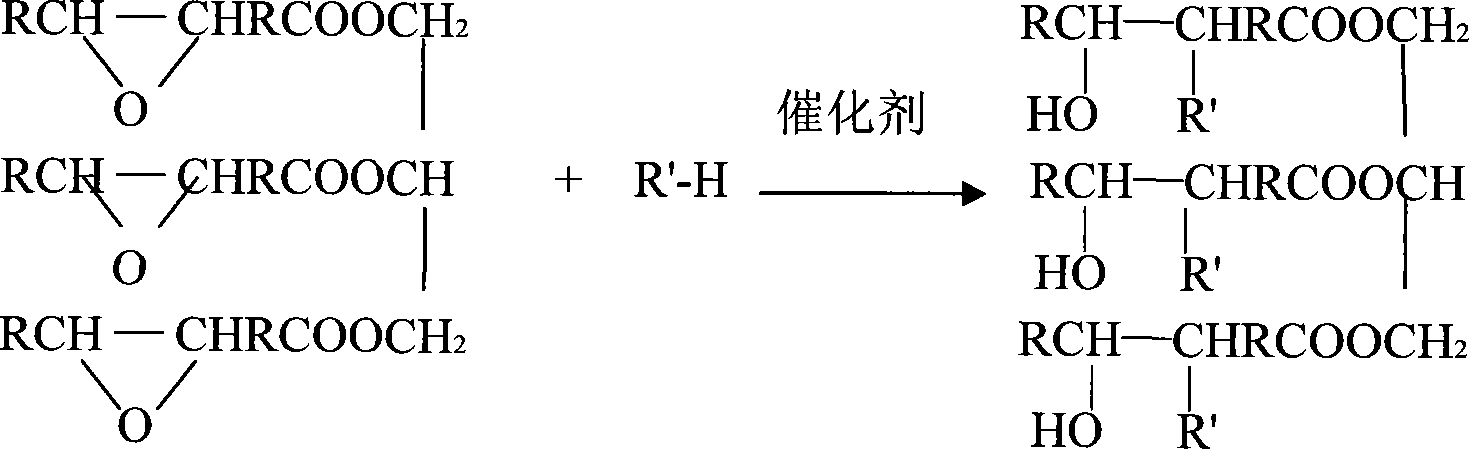

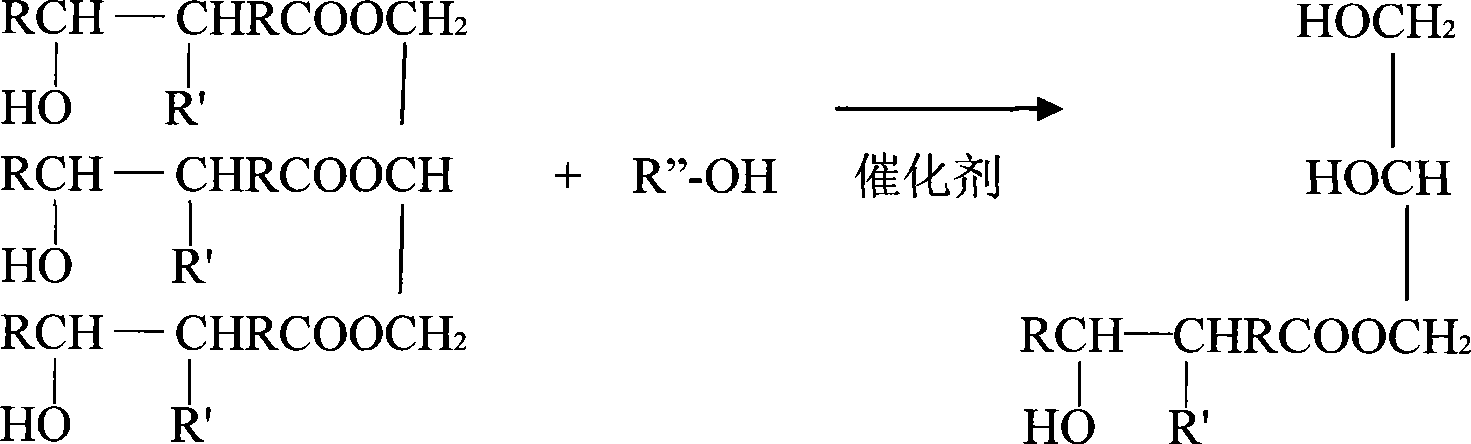

Method used

Image

Examples

Embodiment 1

[0050] 1000g of degummed jatropha oil, 120g of formic acid (80%), 33.5g of 50% sulfuric acid were added to a 2L glass kettle, stirred, and 452g of 37% hydrogen peroxide was added dropwise. After reacting for 4 to 10 hours, stand still and separate layers to separate the acidic water, use sodium carbonate aqueous solution to adjust the pH value of the oil phase, remove water in vacuum and filter. Obtain 1001 g of epoxy jatropha oil, and the epoxy value is 4.0%.

Embodiment 2

[0052] Add 1000g of refined jatropha oil, 230g of acetic acid, and 43.8g of 50% phosphoric acid into a 2L glass kettle, stir, add 471g of 35% hydrogen peroxide dropwise, and react for 4 to 10 hours at a temperature of 30 to 70°C. Set the layers to separate the acid water, adjust the pH value of the oil phase with an aqueous solution of sodium carbonate, remove water in a vacuum and filter. Obtain 996g of epoxy jatropha oil, and the epoxy value is 3.92%.

Embodiment 3

[0054] Add 1000 g of epoxy jatropha oil, the product in Example 1, into a 2L glass kettle, then add 233 g of propylene glycol and 7.9 g of potassium hydroxide, stir and heat up, control the reaction temperature at 65-170° C., and the reaction time for 5-10 hours. Add 252g of glycerol, control the temperature at 120-240°C, carry out the alcoholysis reaction for 4 hours, and then remove small molecules in vacuum, and analyze the crude product with a hydroxyl value of 497mgKOH / g. After refining, 1389g of refined bio-based polyols were obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com