Polysilazane-treating solvent and method for treating polysilazane by using such solvent

A polysilazane and solvent technology, which is applied in the field of polysilazane treatment solvents, can solve the problems that polysilazane cannot be cleaned or peeled off satisfactorily, film separation, cracks, etc., and achieve excellent polysilazane Solubility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-26 and comparative example 1-7

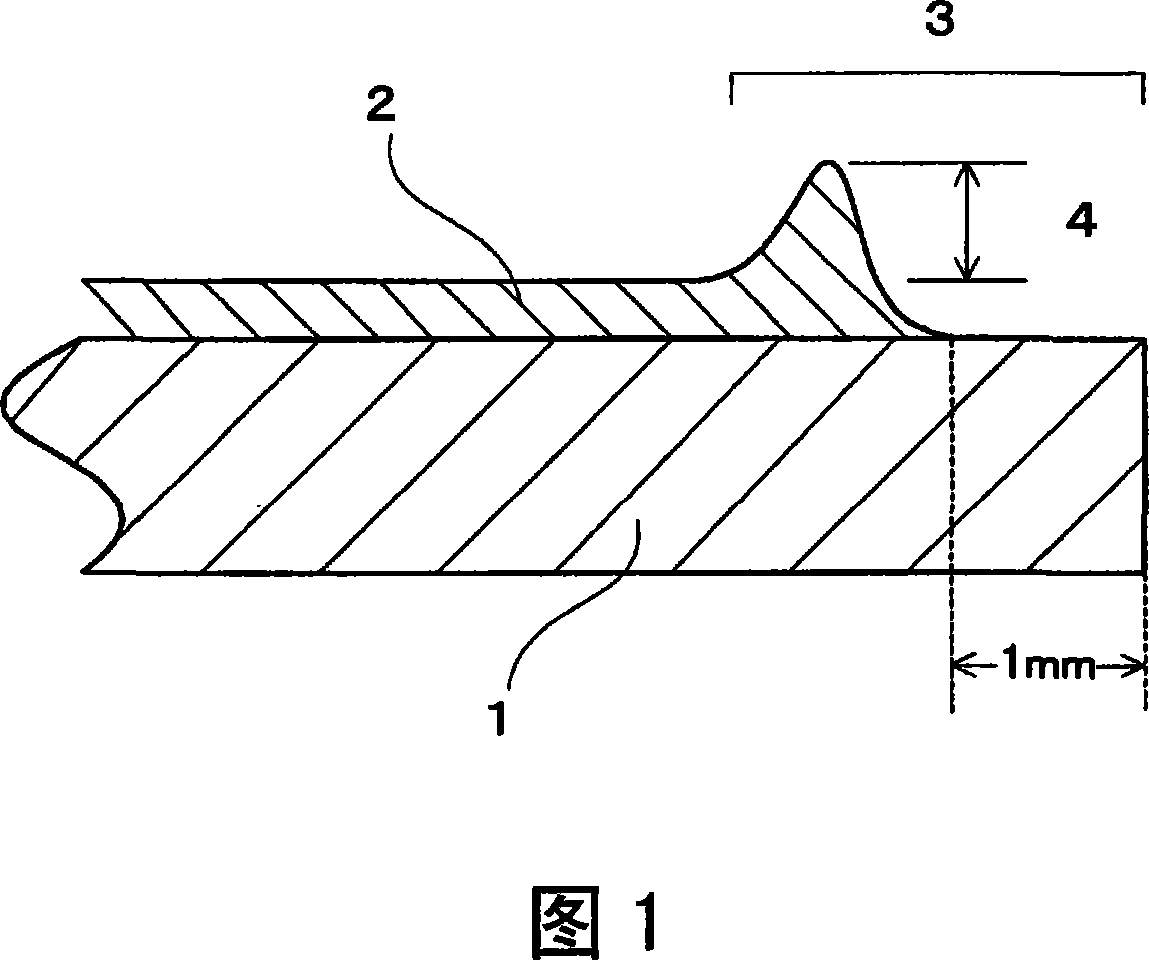

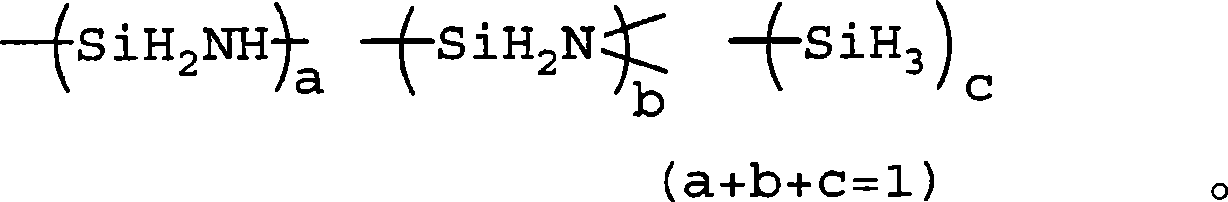

[0065] Provide the processing solvent and polysilazane shown in Table 1, that is, perhydropolysilazane as described in Reference Examples 1-3 of Patent Document 1, polysilazane to which methanol is added, and hexamethylsilazane to which A polysilazane based disilazane, and an aluminum-containing polysilazane as described in Example 1 of Patent Document 2. For free-standing polysilazane, the days required for gelation, the amount of gas released, and the properties of the edge-cut portion were evaluated as follows.

[0066] (method for assessing the number of days required to gel)

[0067] A 20 wt % solution (5 g) of each polysilazane compound in di-n-butyl ether and 50 g of a processing solvent were placed in a glass bottle (100 g) and mixed together. In a room under the conditions of 22° C. and 50% RH, the glass bottle was opened and placed, and the number of days required for the gel was visually observed. Generally, the number of days required for gelation is preferably 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com