Biochemical inspection device and biochemical inspection method

An inspection device and inspection method technology are applied in the field of devices for analyzing biochemical reactions, and can solve problems such as reducing and increasing the burden on inspectors, failing to obtain fluorescence image inspection efficiency, and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

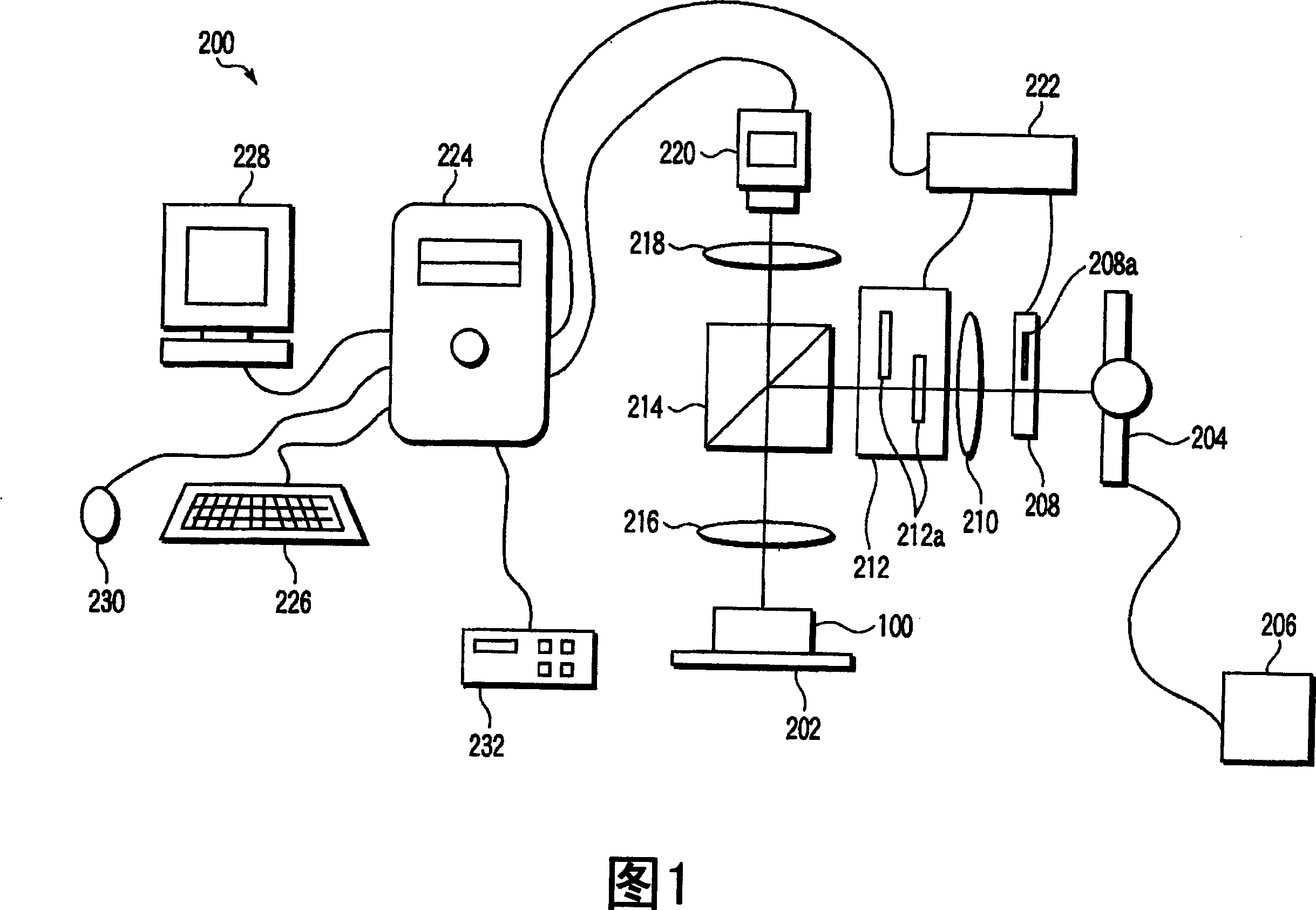

[0025] FIG. 1 shows the configuration of a biochemical testing device according to an embodiment of the present invention. In FIG. 1 , the excitation light source 204 is various lamps such as a mercury light source or an LED, and is connected to a power supply unit 206 . A shutter unit 208 incorporating a shutter 208 , a lens 210 , a filter unit 212 incorporating two excitation filters 212 a , and a dichroic mirror 214 are disposed on the optical path of excitation light emitted from the excitation light source 204 . An objective lens 216 and a stage 202 on which the array 100 for biochemical inspection is placed are arranged on the reflection optical path of the dichroic mirror 214 . In addition, an imaging lens 218 and a CCD camera 220 serving as an imaging element are disposed on the transmission optical path of the dichroic mirror 214 . The CCD camera 220 includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com