Preparation method of foam glass

A technology of foam glass and waste glass, which is applied in the field of preparation of foam glass, can solve the problems of reducing product cost by solid waste, and achieve the effects of environmental protection, promotion of utilization, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

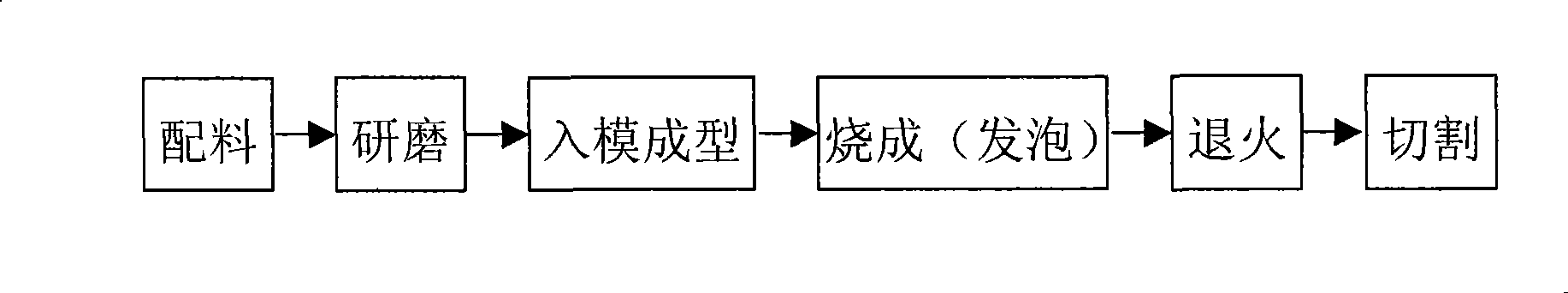

Image

Examples

Embodiment 1

[0011] Embodiment 1: Take the preparation of 100kg mixed powder as an example. Crush and mix 25kg of fly ash and 60kg of waste glass evenly. After grinding for 4 hours to reach 200 mesh, add 7kg of calcium carbonate, 2kg of potassium nitrate, 1kg of sodium nitrate, 2kg of sodium carbonate, 1kg of lithium carbonate, 1.6kg of water glass, fiber The powder is 0.4kg, after adding additives, the powder is put into the mold, dried and fired, the firing temperature is controlled at 780°C-820°C, kept for 1-2 hours, quickly cooled to 600°C, and the annealing temperature is 550°C to room temperature After 10 hours, it was annealed and cooled to room temperature, and sent to be cut and shaped.

Embodiment 2

[0012] Embodiment 2: Take the preparation of 100kg mixed powder as an example. Crush and mix 22kg of fly ash and 66kg of waste glass evenly, grind to 200 mesh for 4 hours, add 5kg of calcium carbonate, 1kg of potassium nitrate, 2kg of sodium nitrate, 1kg of sodium carbonate, 1kg of lithium carbonate, 1.5kg of water glass, and 0.5 kg of cellulose kg, mixed evenly into a mold, dried and fired in a kiln, the firing temperature is controlled at 760°C to 810°C, kept for 1.5 to 3.0 hours, quickly cooled to 580°C, annealed and cooled to room temperature, and sent to be cut and shaped.

Embodiment 3

[0013] Embodiment 3: Take the preparation of 100kg mixed powder as an example. Crush and mix 20kg of fly ash and 70kg of waste glass, grind them to 200 mesh, add 3kg of calcium carbonate, 1.3kg of potassium nitrate, 1.7kg of sodium nitrate, 1.5kg of sodium carbonate, 0.5kg of lithium carbonate, 1kg of water glass, and 1kg of cellulose , mixed evenly into the mold for molding, dried and fired in a kiln (high temperature furnace), the firing temperature is controlled at 750°C to 800°C, kept for 1.5 to 2.5 hours, quickly cooled to 580°C, annealed and cooled to room temperature, and sent for cutting and molding .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com