Anti-scaling, anti-corrosive and sand prevention ceramic oil-well pump and manufacturing method therefor

A technology of oil well pump and ceramic pump, applied in the direction of pump, pump element, earth-moving drilling, etc., can solve the problems of short pump inspection period, shut-in and production stop, little progress, etc., and achieve reliable performance, long service life and high pump efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is provided by the following embodiments, which will be described below in conjunction with the accompanying drawings.

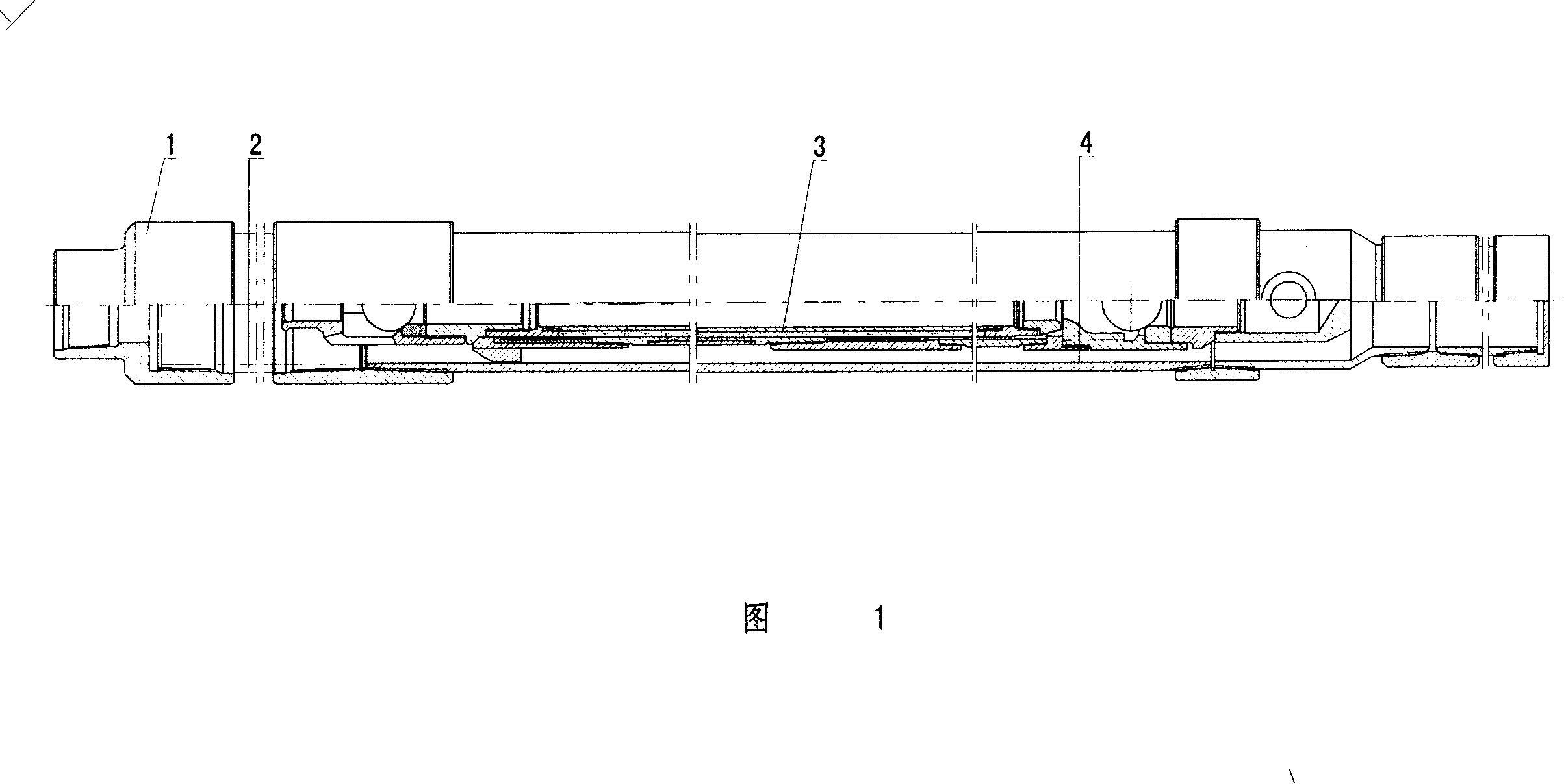

[0016] As shown in FIG. 1 , the present invention is composed of an oil pipe buckle joint 1 , an oil pipe 2 , a pump barrel assembly 3 , and a plunger assembly 4 . Its structure and assembly relationship are as follows: oil pipe variable buckle joint 1 is threaded to connect the oil production pipe string, and the oil pipe 2 is connected to the bottom, the oil pipe 2 is then threaded to the pump barrel assembly 3, and the plunger assembly 4 is placed in the pump barrel assembly 3 .

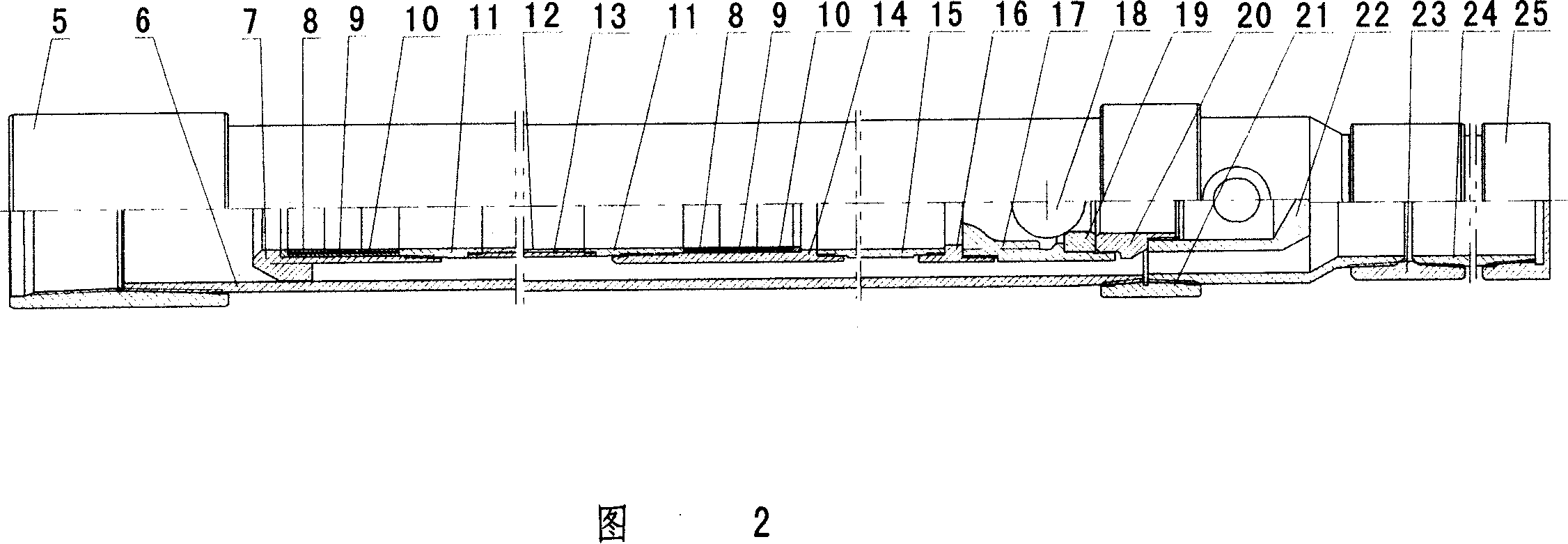

[0017] As shown in Figure 2, the pump barrel assembly of the present invention consists of an outer tube upper collar 5, an outer tube 6, a pump barrel centering head 7, a scraper ring, a sand scraper ring 8, a ring group outer cover 9, a spring sleeve 10, and a pump barrel Connector 11, ceramic pump barrel 12, pump barrel jacket 13, pump barrel low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com