Gas nozzle for arc welding

A gas nozzle and arc welding technology, applied in arc welding equipment, welding equipment, welding accessories, etc., can solve the problems of hindering the flow of shielding gas, burning the welding torch 21, and reducing welding quality, so as to improve welding quality and welding operation performance, ensure protection, and achieve the effect of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

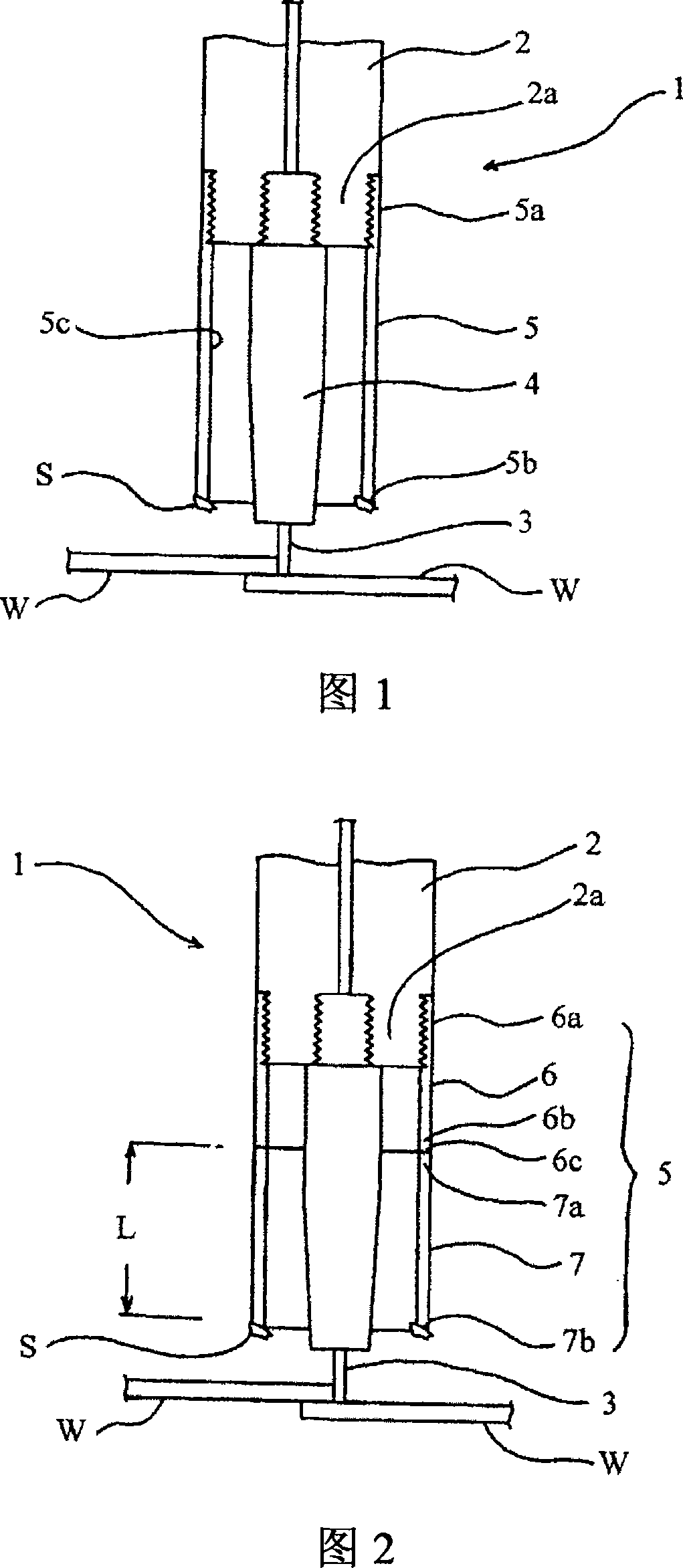

[0033] Fig. 1 is a schematic cross-sectional view of a welding torch equipped with a gas nozzle according to a first embodiment of the present invention.

[0034] In the welding torch 1, a metal contact tip 4 is detachably screwed and fastened to the front end 2a of the welding torch head 2, which is used to supply the welding wire 3 as a consumable electrode, and at the same time, the base of the gas nozzle 5 The end 5a is screwed and fastened to the front end 2a of the torch head 2, and a gas nozzle 5 is detachably installed so as to surround the contact nozzle 4, and the gas nozzle 5 extends from the base end 5a side as a gas jet The nozzle tip 5b on the exit side is formed in a cylindrical shape.

[0035] In addition, the welding wire 3 is used as the electrode on the positive electrode side, and the workpiece W, which is the part to be welded, is used as the electrode on the negative electrode side, while argon and CO are fed into the gas nozzle 5. 2 The inert gas is used as ...

no. 2 Embodiment approach

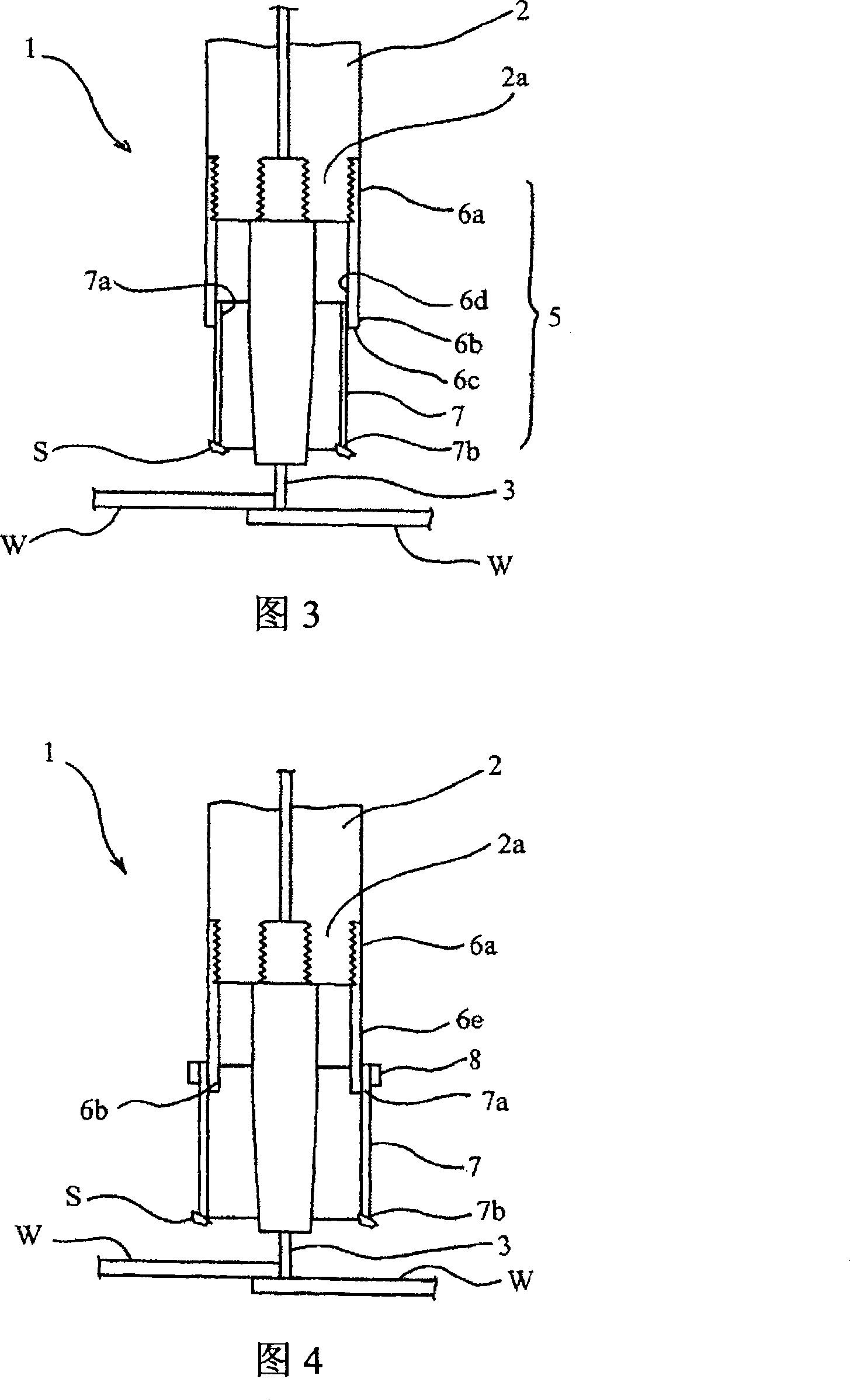

[0042] Fig. 2 is a schematic cross-sectional view of a welding torch equipped with a gas nozzle according to a second embodiment of the present invention.

[0043] In this embodiment, based on the first embodiment, the gas nozzle 5 is made up of the following parts: a cylindrical metal base end nozzle 6 whose base end 6a is detachably screwed and fastened to the welding torch Head 2 on the front end portion 2a; and the front end side nozzle 7, the base end portion 7a of which is detachably bonded to the end surface 6c of the front end portion 6b of the base end side nozzle 6, and the front end side nozzle 7 is made of cardboard The cardboard is a material that is carbonized due to the adhesion of spatter S, and the carbonized part falls off together with the spatter S, and the tip side nozzle 7 extends from the base end 7a side to the tip of the nozzle as the gas ejection side 7b is formed in a cylindrical shape, and since the other structure of the welding torch 1 is the same as ...

no. 3 Embodiment approach

[0046] Fig. 3 is a schematic cross-sectional view of a welding torch equipped with a gas nozzle according to a third embodiment of the present invention.

[0047] In this embodiment, on the basis of the second embodiment, the base end portion 7a of the tip end side nozzle 7 is inserted / detachably bonded to the inner peripheral surface 6d of the tip end portion 6b of the base end side nozzle 6, and the welding torch The other structure of 1 is the same as that of FIG. 2, and a detailed description of the part is omitted by attaching the same reference numerals to the parts corresponding to FIG. 2.

[0048] According to this embodiment, in addition to obtaining the same effect as the second embodiment, compared with the case where the tip side nozzle 7 is bonded to the tip surface 6c of the proximal side nozzle 6 as in the second embodiment, it is possible to use The insertion of the tip nozzle 7 is easier, the replacement operation can be performed smoothly, and maintenance is simp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com