Temperature setting method for heat treating plate, temperature setting device for heat treating plate, program and computer-readable recording medium recording program

A temperature setting and temperature correction technology, which is applied in the field of temperature setting, device, program and computer-readable recording medium for recording the heat treatment plate, can solve the problems such as temperature deviation of the wafer surface, and improve the finished product. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

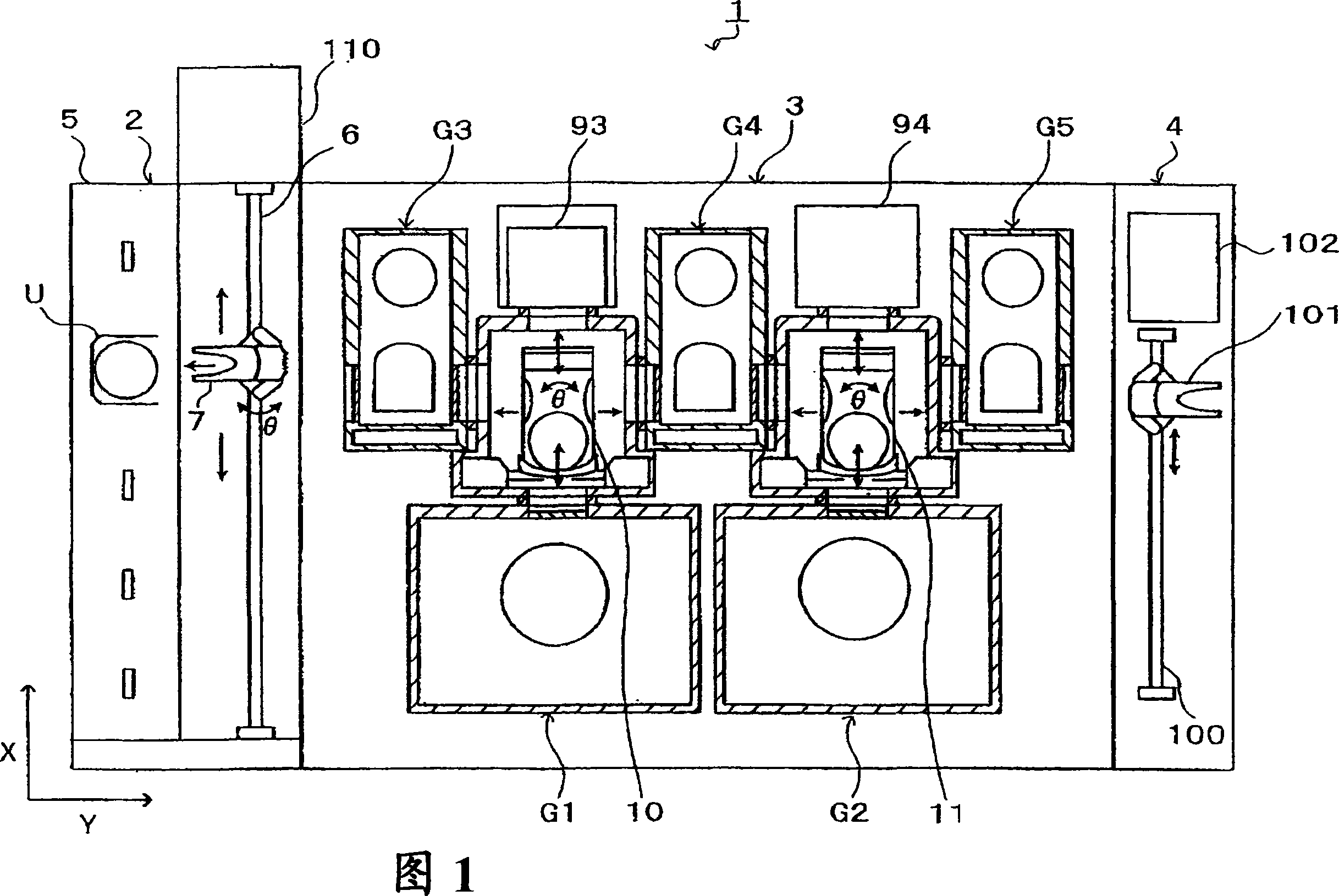

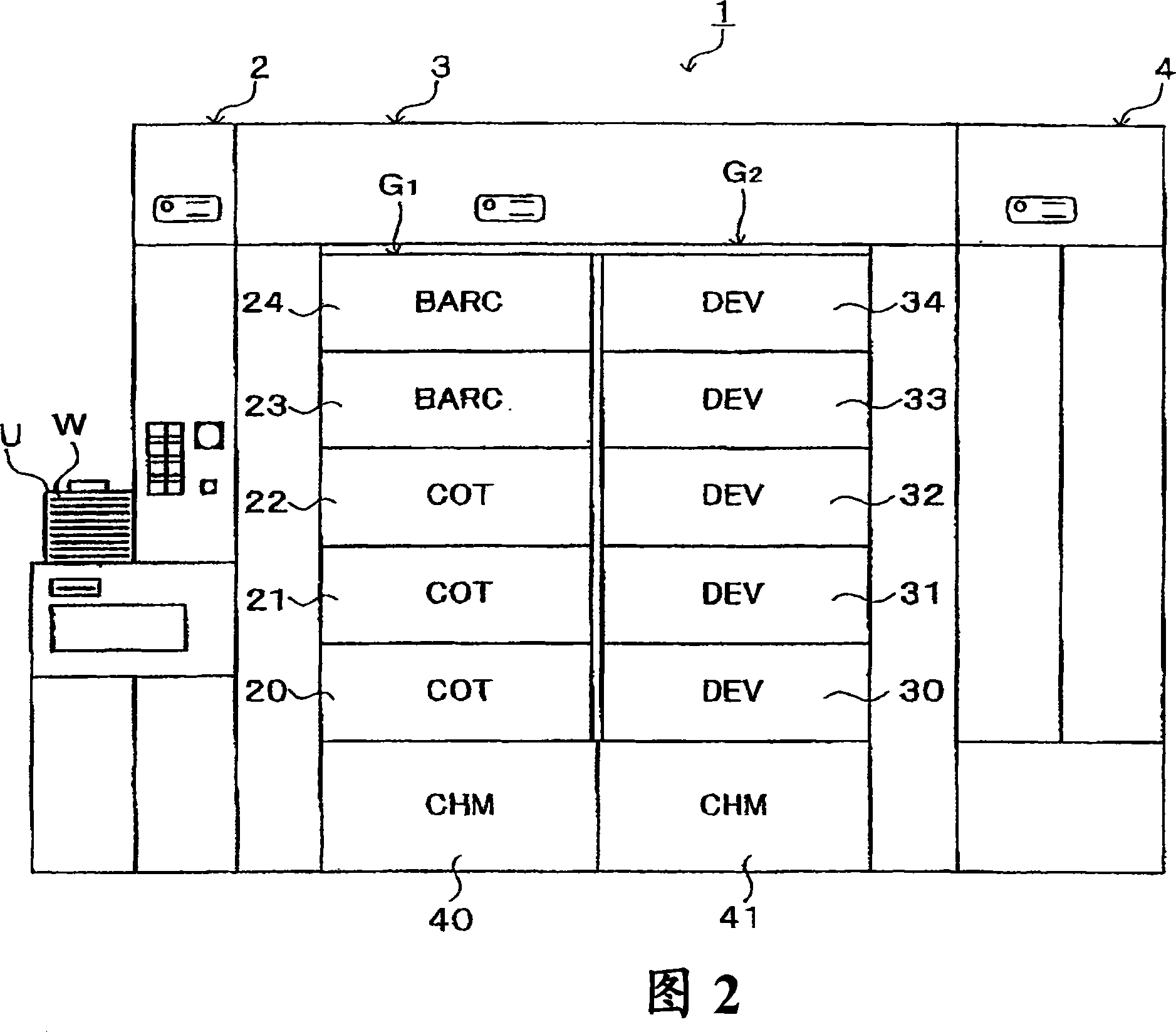

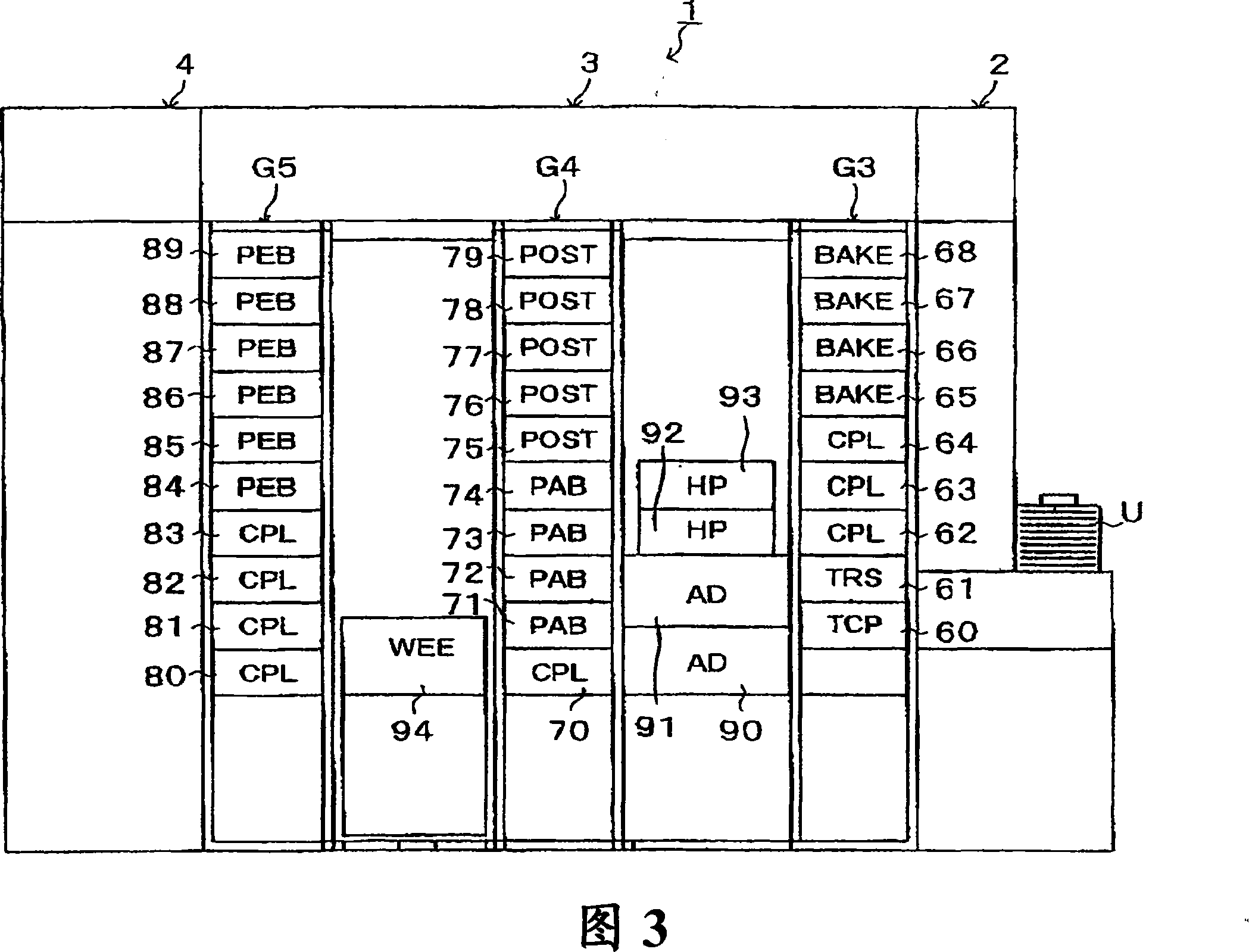

[0029] Hereinafter, the most preferred embodiment of the present invention will be described. Fig. 1 is a plan view schematically showing the structure of a coating and developing processing system 1 provided in a temperature setting device for a heat treatment plate according to this embodiment, Fig. 2 is a front view of the coating and developing processing system 1, and Fig. 3 is a coating and developing processing Rear view of System 1.

[0030] The coating and development processing system 1 has, as shown in FIG. The cartridge station 2 of the lithography process, and a plurality of various processing devices that implement predetermined processing in a single-wafer manner in the photolithography process are arranged in multiple layers. The processing station 3 is adjacent to the processing station 3 and an exposure device (not shown ), the structure in which the interface portion 4 receiving the wafer W is integrally connected.

[0031] The cassette station 2 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com