Preparation method for lubricating oil

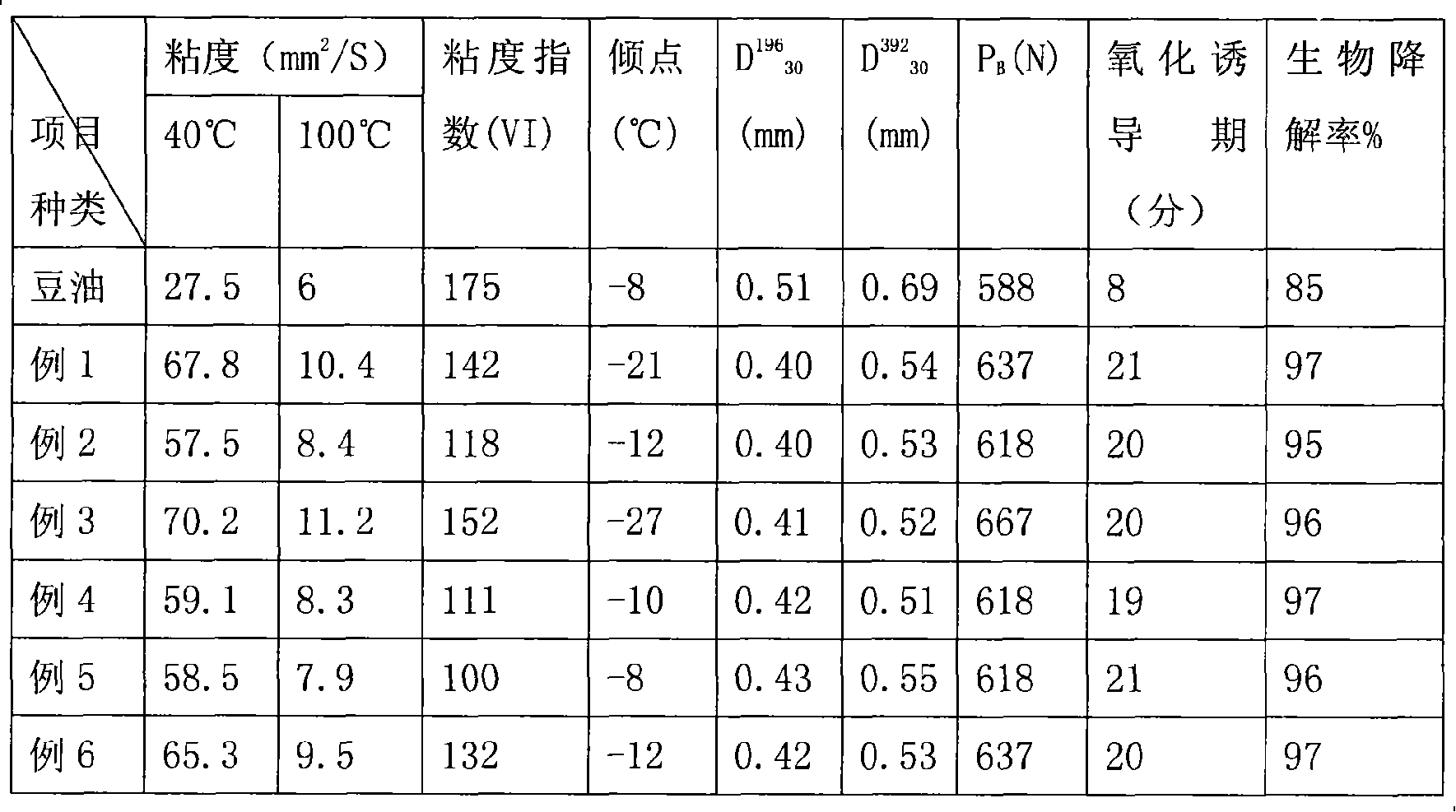

A technology of lubricating oil and oil phase, applied in the field of lubricating oil technology, can solve the problems of poor rheological properties of vegetable oil, and achieve the effect of improving rheological properties, low pour point and good rheological properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] a) Weigh a certain amount of soybean oil and isooctyl alcohol, the molar ratio of soybean oil and isooctyl alcohol is 1:6, put it in a three-necked flask, use concentrated sulfuric acid as a catalyst, stir and react at 120°C for 2 hours, and after cooling, Pour out the reaction material, put it in a separatory funnel, wash it with water until neutral, release the water in the lower layer after layering, pour the oil phase into a three-necked flask, and distill at 80°C, and place the obtained transesterification product in a three-necked flask middle.

[0019] b) Insert a certain amount of formic acid, H 2 o 2 The dropping funnel of the mixed solution, the molar ratio of transesterified soybean oil, hydrogen peroxide, and formic acid is 1:2, keep the temperature at 40°C, add the mixed solution dropwise while stirring, and complete the dropwise addition within 2 hours. Keep the temperature at 40°C, continue the reaction at this temperature for 24 hours, pour out the rea...

Embodiment 2

[0023] a) Weigh rapeseed oil and isopropanol, the molar ratio of rapeseed oil to isopropanol is 1:3, place in a three-necked flask, use concentrated sulfuric acid as a catalyst, stir and react at 100°C for 1 hour, and after cooling, Pour out the reaction material, put it in a separatory funnel, wash it with water until neutral, release the water in the lower layer after layering, pour the oil phase into a three-necked flask, and distill at 80°C, and place the obtained transesterification product in a three-necked flask middle.

[0024] b) Insert a certain amount of formic acid, H 2 o 2 The dropping funnel of the mixed solution, the molar ratio of transesterified rapeseed oil and hydrogen peroxide is 1:3, keep the temperature at 60°C, add the mixed solution dropwise while stirring, and complete the dropwise addition within 1 hour. Keep the temperature at 60°C, continue the reaction at this temperature for 6 hours, pour out the reaction material, put it in a separatory funnel,...

Embodiment 3

[0028] a) Weigh sunflower oil and isononanol, the molar ratio of sunflower oil and isononanol is 1:9, place in a three-necked flask, use concentrated sulfuric acid as a catalyst, stir and react at 140°C for 3 hours, and react after cooling Pour out the material, put it in a separatory funnel, wash it with water until neutral, release the water in the lower layer after layering, pour the oil phase into a three-necked flask, and distill at 100°C, and place the obtained transesterification product in a three-necked flask .

[0029] b) Insert a certain amount of formic acid, H 2 o 2 The dropping funnel of the mixed solution, the molar ratio of transesterified sunflower oil and hydrogen peroxide is 1: 1.5, keep the temperature at 50°C, add the mixed solution dropwise while stirring, and complete the dropwise addition within one hour. Keep the temperature at 50°C, continue the reaction at this temperature for 12 hours, pour out the reaction material, put it in a separatory funnel,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wear scar diameter | aaaaa | aaaaa |

| Wear scar diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com