Making method for flexible dye sensitized solar battery nano crystal thin film

A dye-sensitized, solar cell technology, applied in the field of nanocrystalline photoanode film manufacturing, to improve cell efficiency and facilitate diffusion and adsorption

Inactive Publication Date: 2010-11-10

XI AN JIAOTONG UNIV

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

For the low-temperature preparation of the most critical photoanode porous nanocrystalline film in DSC, the first two of the above requirements are relatively easy to achieve, but the third is quite challenging

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Login to View More

Abstract

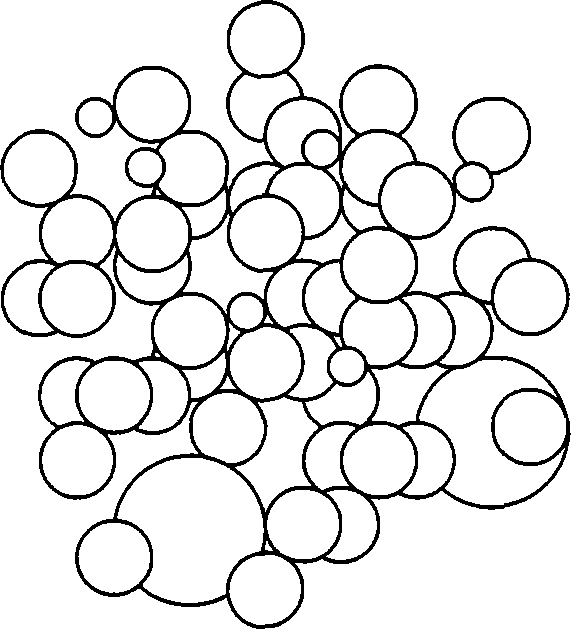

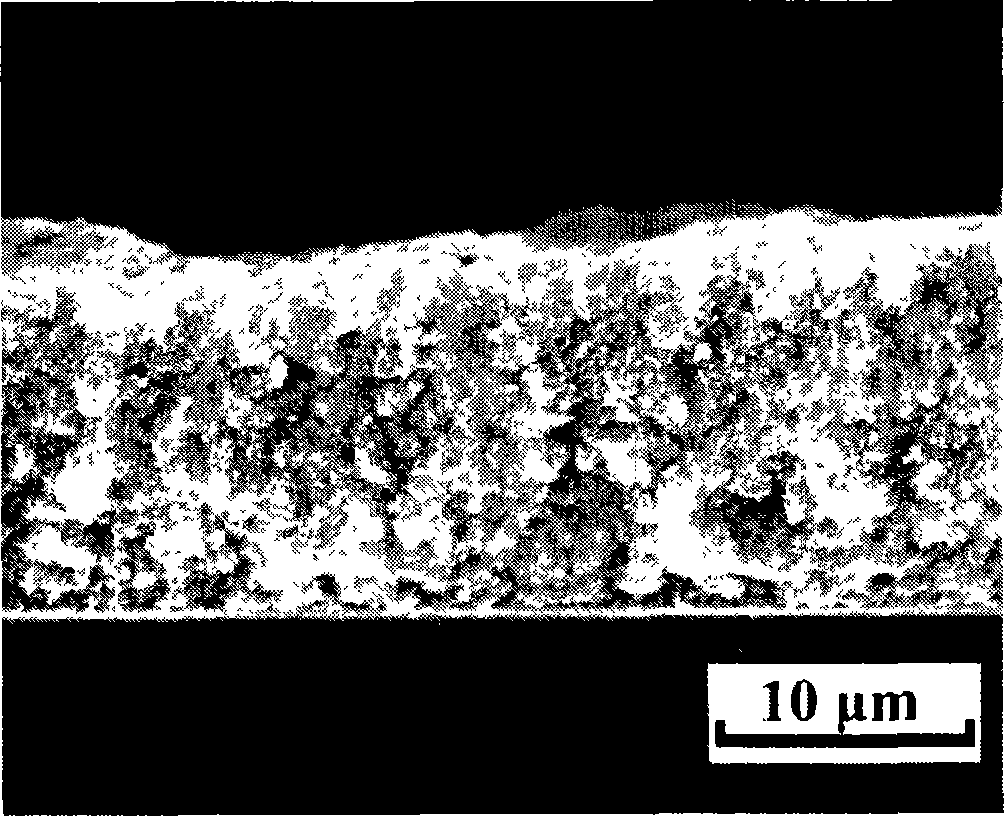

The utility model belongs to field of solar battery, and relates to a manufacturing approach of flexible nanometer-crystalline film of dye sensitizing solar battery, which adopts nanostructured porous TiO2 powder as the material and forms the porous TiO2 film by depositing on a conducting substrate by vacuum deposition. The utility model is characterized in that a porous TiO2 film is made by vacuum cold coating, wherein the nanostructured porous TiO2 powder is accelerated by airflow and impacts on the substrate or the TiO2 coat at a high speed to speed up the combinations of the powder under the pressure of high speed impact at instantaneous high temperature rise; therefore the coat is combined well with the substrate and so are the grains in the coat. The film made by the above approach dose not need to go through high temperature process during manufacturing and after manufacturing, therefore is suitable for manufacture of flexible nanometer-crystalline film of dye sensitizing solarbattery.

Description

Fabrication method of flexible dye-sensitized solar cell nanocrystalline film technical field The invention belongs to the field of solar cells, especially the technical field of dye-sensitized solar cells, and specifically relates to a method for manufacturing a nanocrystalline photoanode film of a flexible dye-sensitized solar cell on a flexible organic polymer conductive substrate. Background technique Solar cells can directly convert solar energy into electrical energy, which is one of the main forms of solar energy utilization. Currently researched solar cells mainly include: silicon solar cells, compound semiconductor cells, polymer film solar cells and dye-sensitized nanocrystalline solar cells. Since the solar energy conversion efficiency of dye-sensitized solar cell (DSC) >7% was reported on Nature in 1991, DSC has received extensive attention. So far, the energy conversion efficiency of DSC has exceeded 11%. According to the state of the electrolyte material...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01L31/18H01L51/48H01L21/36H01L21/28H01G9/20H01G9/04H01M14/00H01M4/04

CPCY02E10/542Y02E10/549Y02E60/12Y02P70/50

Inventor 李长久杨冠军范圣强李成新

Owner XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com