Microwave resonance cavity

A microwave resonant cavity, integrated technology, applied in resonator, plasma, waveguide-type devices and other directions, can solve the problems of unsatisfactory plasma uniformity, poor plasma uniformity, inconvenient disassembly and maintenance, etc., to improve large-area processing capacity , The effect of preventing microwave leakage and convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

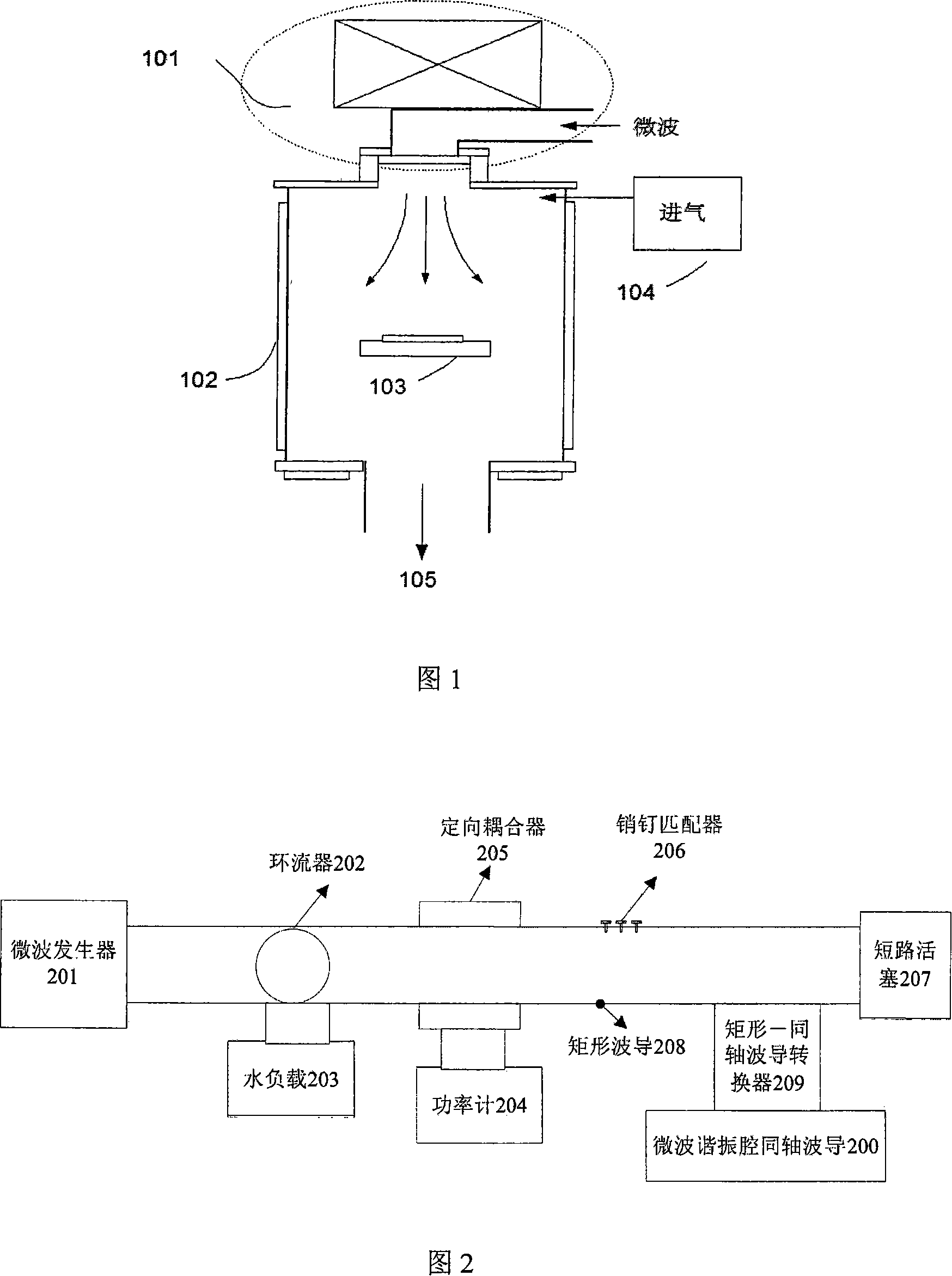

[0021] Figure 2 shows a schematic diagram of the microwave power source and transmission system. The microwave power source and transmission system consists of a microwave generator 201, a circulator 202, a water load 203, a power meter 204, a directional coupler 205, a pin adapter 206, a short-circuit piston 207, a rectangular waveguide 208, and a rectangular-to-coaxial waveguide conversion device 209 and microwave resonator coaxial waveguide 200. The connection relationship of each part is: from left to right, the rectangular waveguide 208 is respectively connected with the microwave generator 201, the circulator 202, the directional coupler 205, the pin matching device 206, the rectangular-coaxial waveguide converter 209, and the short-circuit piston 207 connection; the reflection end of the circulator 202 is connected to the water load 203; the power meter 204 is connected to the directional coupler 205; the rectangular-coaxial waveguide converter 209 is connected to the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com