20butylthio íñtebuconazole water dispersible powder and method of manufacturing the same

A technology of wettable powder and production method, which is applied in the fields of forestry and agriculture, and can solve the problems of insecticidal and bactericidal effects, insecticidal, bactericidal and growth regulation, reduce the effect of pesticide control, increase the cost of control, etc., and increase production. Significant effect, avoid economic loss, reduce the effect of prevention and control costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Firstly mix 5% carbosulfan raw material, 15% tebuconazole, and about 0.1% chitosan, 3% penetrant (optional ammonia ketone or homogeneous raw material) by weight percentage, mixing is Put the raw material, chitosan and penetrating agent into the acetone solution to dissolve and mix; meanwhile, the filler high concrete is pulverized and dried and cooled; then the aforementioned mixed raw material and filler are mixed and 5% of auxiliary agent (stabilizer DMF, etc.), and then measure to ensure a suitable proportion, and then put it into the reactor for reaction; finally, it is mixed by a mixer, packaged by a packaging machine, and then put into the warehouse to obtain 20% butylthiopentazole Alcohol wettable powder finished product.

[0015] Tebuconazole is a high-efficiency broad-spectrum systemic fungicide of triazoles, an alcohol demethylation inhibitor, and a high-efficiency fungicide for seed treatment or foliar spraying of important economic crops. It has good protec...

Embodiment 2

[0018] First weight percentage mixes the carbosulfan of raw material 4%, the tebuconazole of 13%, and the chitosan of 0.1%, the penetrating agent of 4% (optional azone or homogeneous raw material), mixing is to mix Raw material and chitosan, penetrating agent are put into acetone solution and dissolved and mixed; Simultaneously, the filler high concrete is pulverized and dried and cooled; Then the aforementioned mixed raw material and filler are mixed and 8% auxiliary agent (stabilizer DMF ), and then measure to ensure the proper proportioning, then put it into the reactor for reaction; finally mix it with a mixer, pack it with a packaging machine, and put it into the warehouse to obtain 20% butylthio tebuconazole. Finished wet powder.

Embodiment 3

[0020] First weight percentage mixes the carbosulfan of raw material 6%, the tebuconazole of 18%, and the chitosan of 0.1%, the penetrating agent of 5% (optional ammonia ketone or homogeneous raw material), mixing is to mix Raw materials, chitosan and penetrating agent are put into acetone solution to dissolve and mix; meanwhile, the filler high concrete is crushed and dried and cooled; ), and then measure to ensure the proper proportioning, then put it into the reactor for reaction; finally mix it with a mixer, pack it with a packaging machine, and put it into the warehouse to obtain 20% butylthio tebuconazole. Finished wet powder.

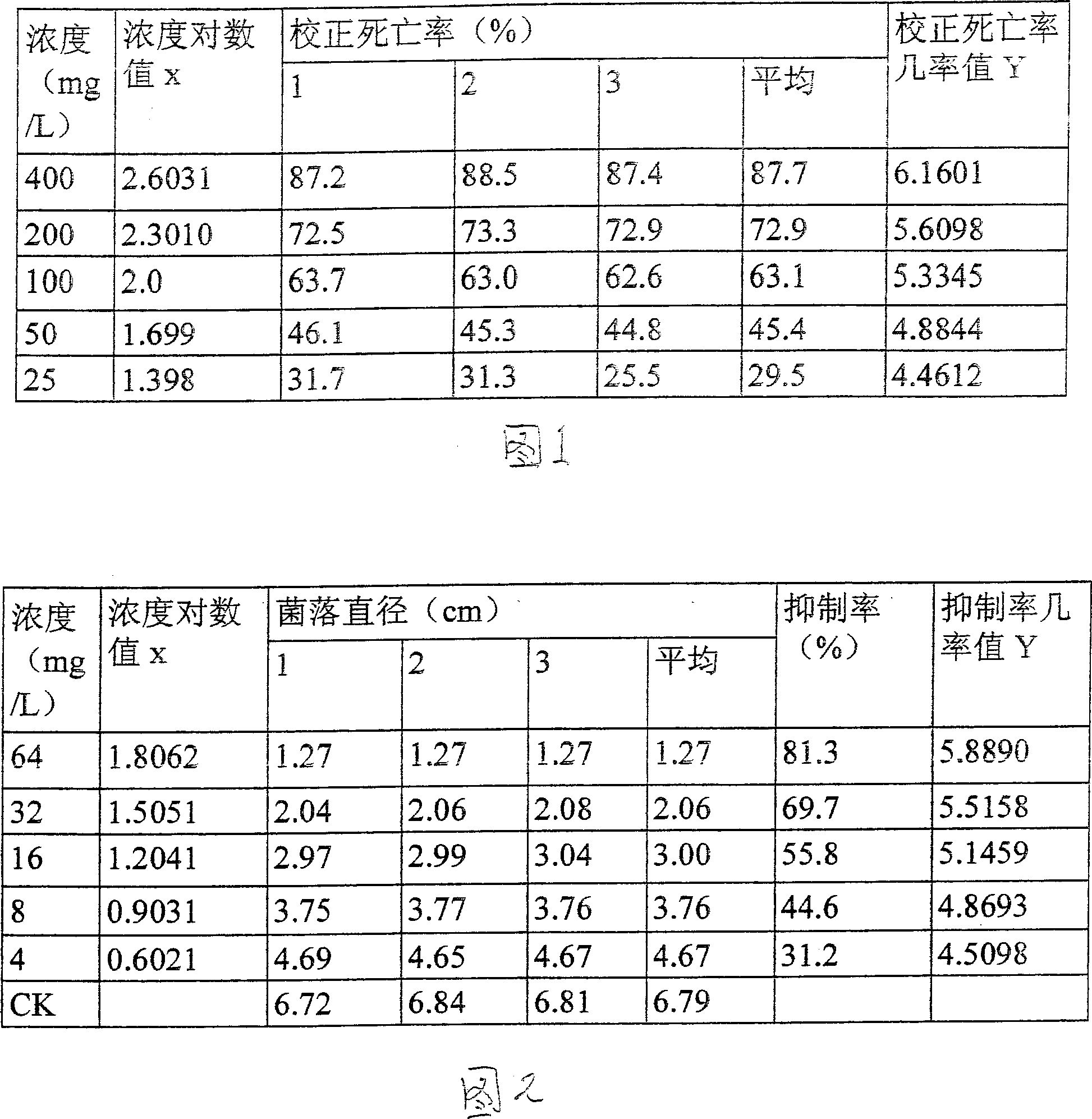

[0021] 20% butylthio tebuconazole wettable powder toxicity test report:

[0022] 1. Sample sending unit: Jiangsu Nantong Hongyang Chemical Co., Ltd.

[0023] 2. Sample delivery time: September 10, 2006

[0024] 3. Sample delivery location: Plant Disease Test Station

[0025] 4. Sample name: 20% butylthio-tebuconazole wettable powder

[0026]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com