Ammonia water absorbing refrigerator

An absorption refrigerator and ammonia water technology, applied in refrigerators, adsorption machines, refrigeration components, etc., can solve the problems of short preservation time of seafood, large loss of ice, and bulky volume, and solve the problem of countercurrent heat transfer, The effect of high efficiency and simplified system process and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

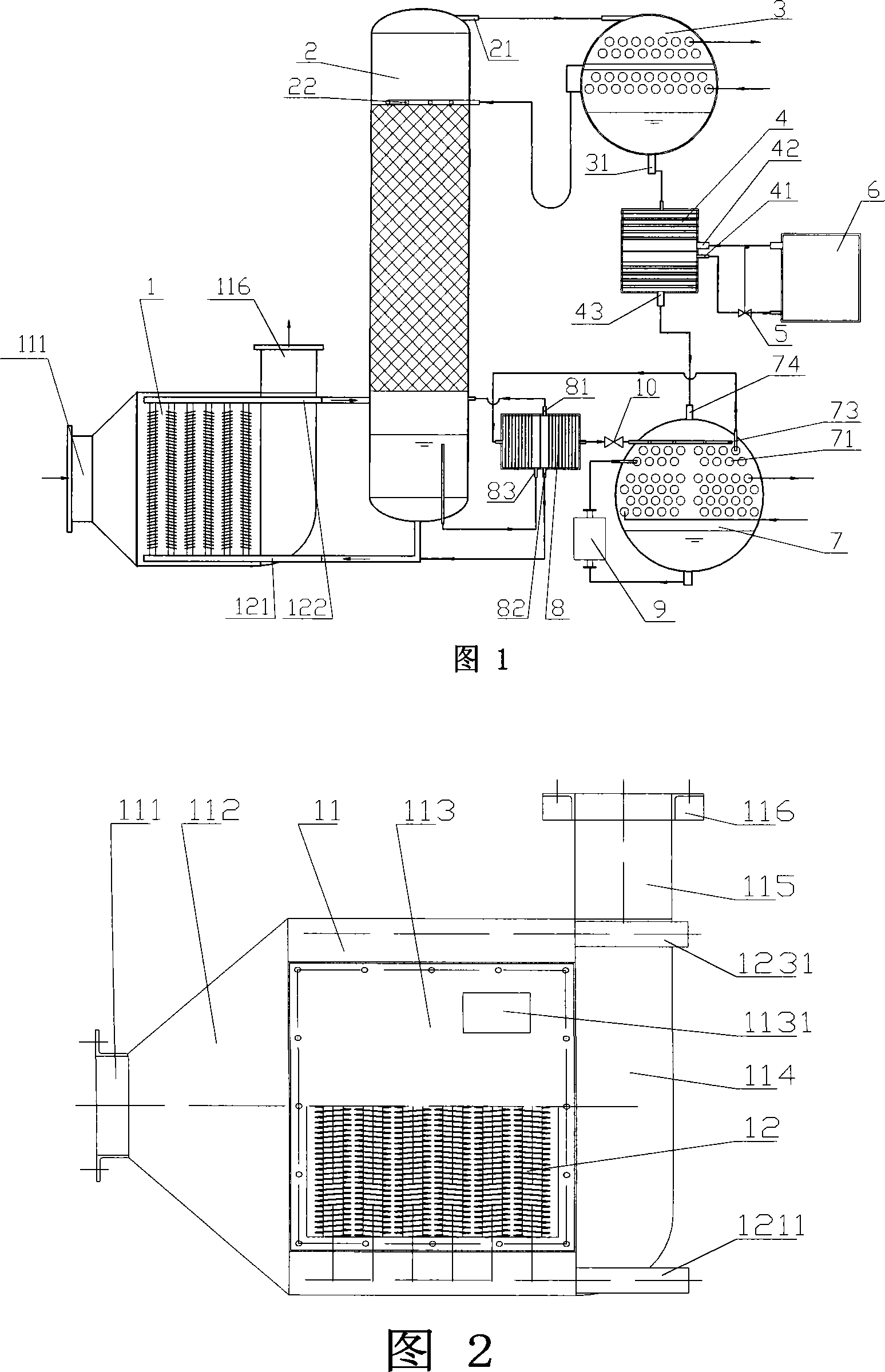

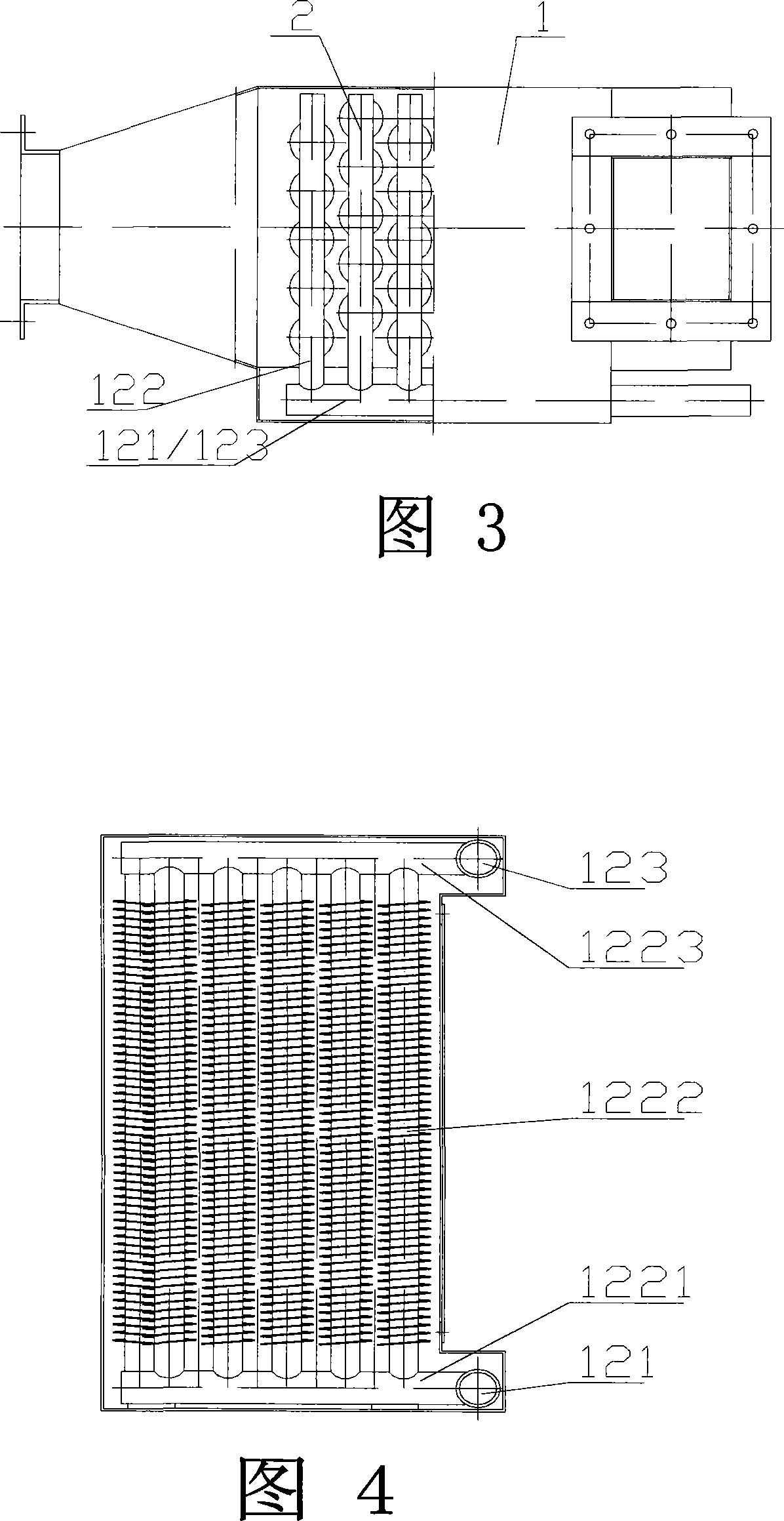

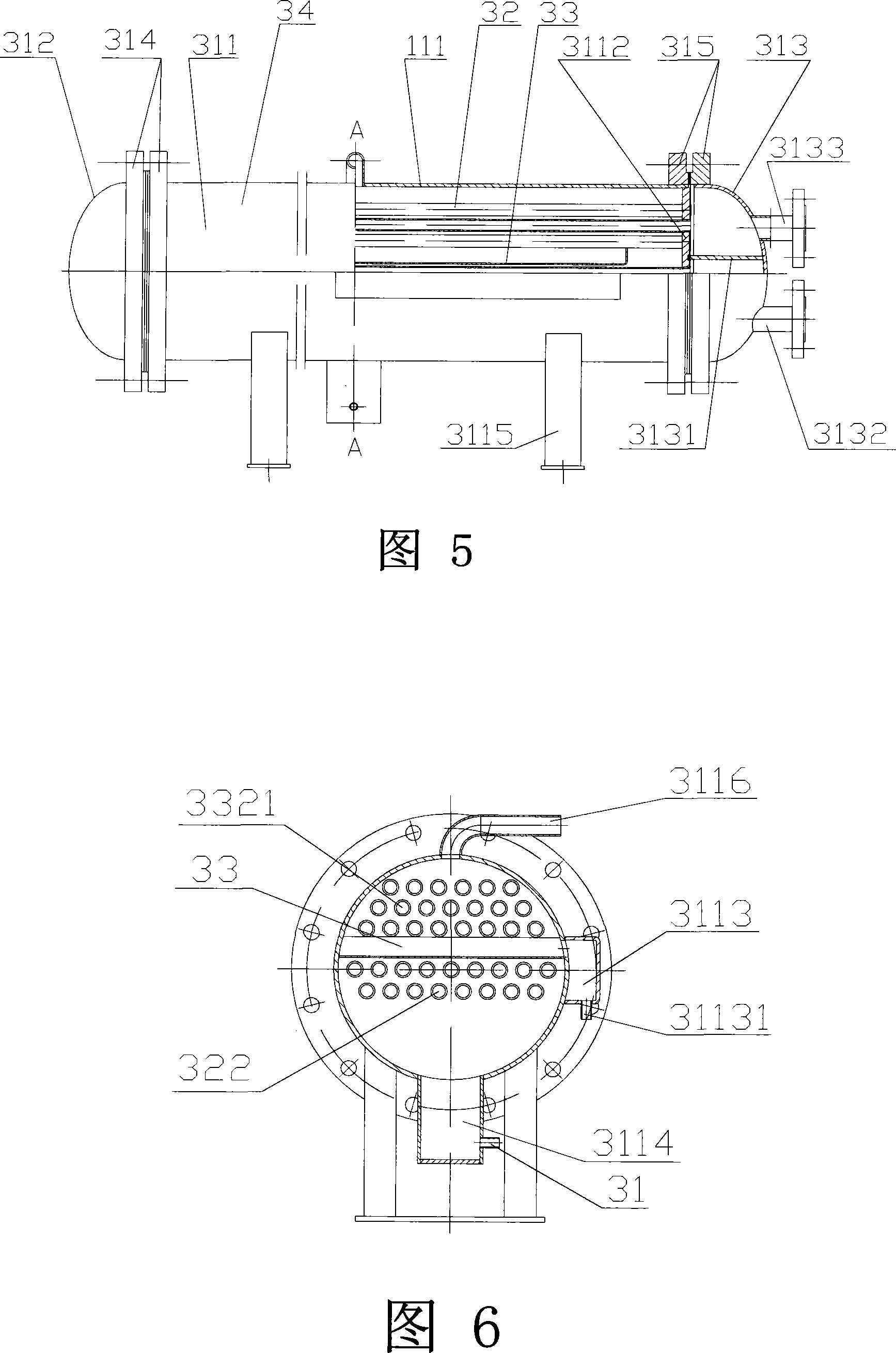

[0027] As shown in Figure 1, it includes generator 1, rectification tower 2, condenser 3, subcooler 4, expansion valve 5, evaporator 6, absorber 7, solution heat exchanger 8, solution pump 9, throttle valve 10. Generator 1 is provided with tail gas inlet 111 and tail gas outlet 116 respectively, and generator 1 is connected with rectification tower 2 through lower header inlet pipe 121 and upper header outlet pipe 122; rectification tower 2 is connected with ammonia gas outlet pipe 21 , Ammonia liquid spray pipe 22 is connected with condenser 3; Condenser 3 is connected with supercooler 4 through condenser ammonia liquid outlet pipe 31, and supercooler 4 adopts the spiral plate heat exchanger with different channel spacings, and supercooler 4 The ammonia liquid outlet pipe 41 of the subcooler, the ammonia gas inlet pipe 42 of the supercooler are connected with the evaporator 6, the supercooler 4 is connected with the absorber 7 through the ammonia outlet pipe 43 of the supercoo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com