Laser scattering detecting system of optical flat surface blemishes

An optical plane and laser scattering technology, which is applied in the field of optical planes, can solve problems such as beam quality degradation, failure to meet requirements, and damage to optical components, to achieve accurate and stable detection, improve resolution and accuracy, and improve signal-to-noise ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

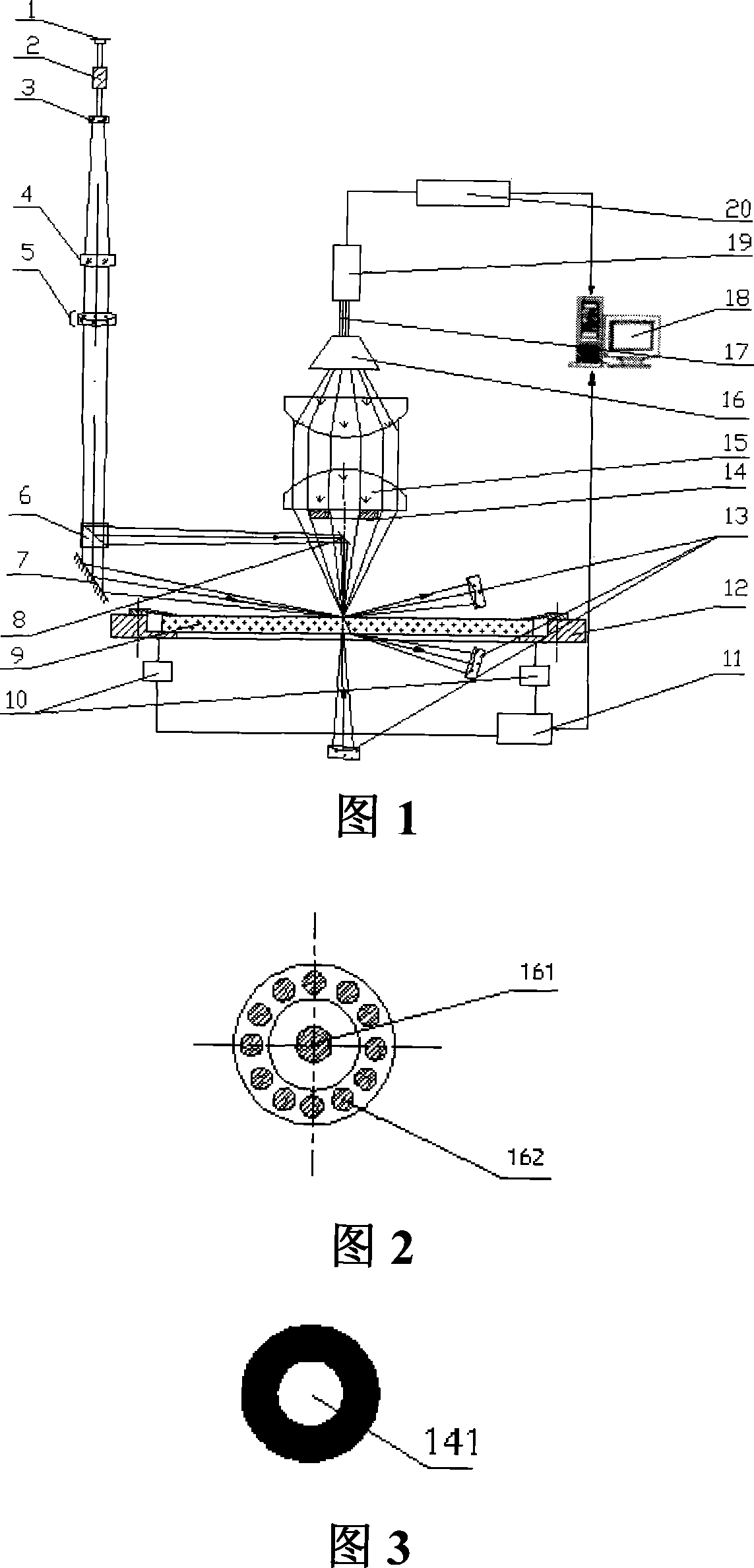

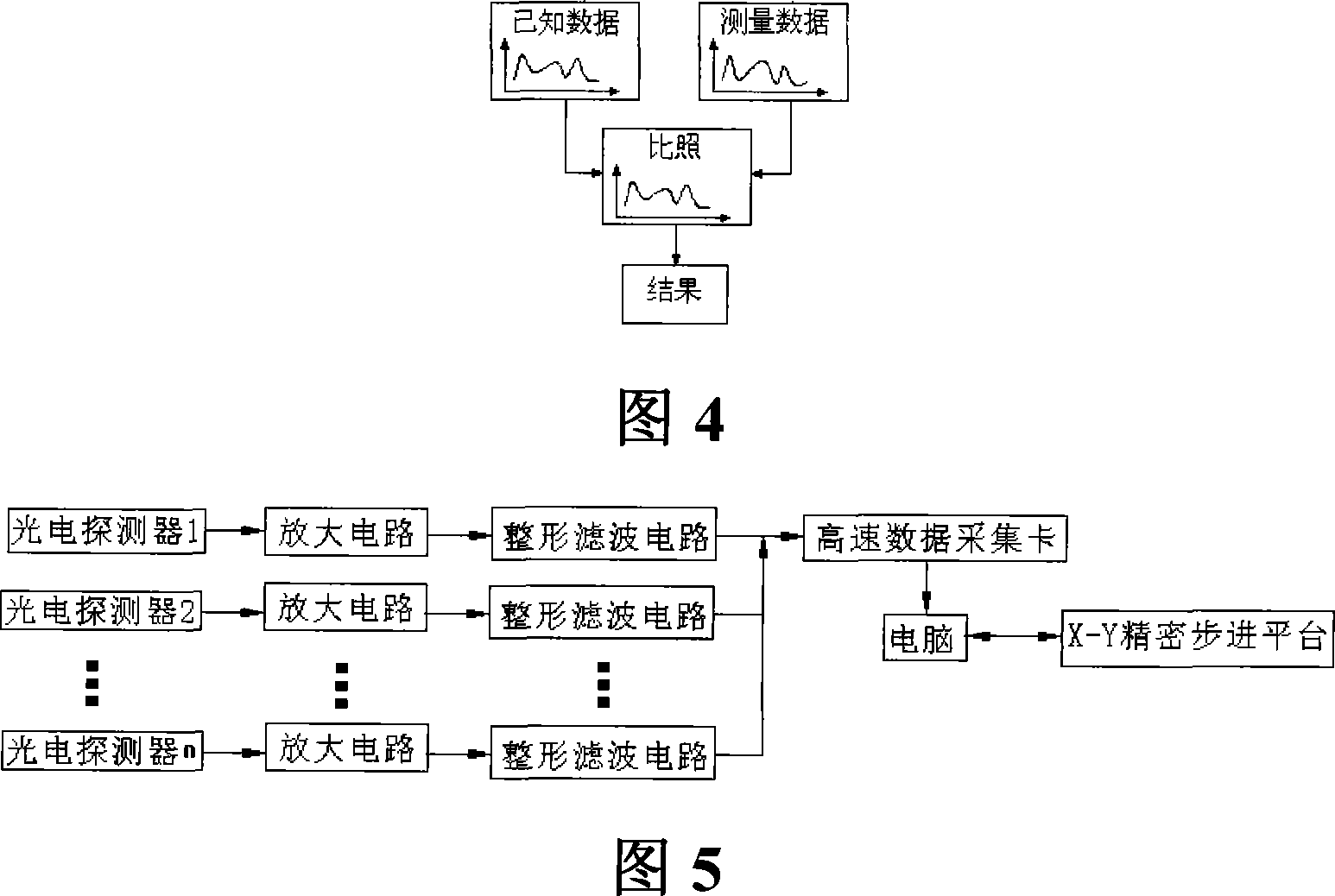

[0031] Please refer to FIG. 1 first. FIG. 1 is a schematic diagram of the principle of the laser light scattering detection system for optical flat surface defects of the present invention. It is also a structural schematic diagram of the preferred embodiment of the present invention. It can be seen from the figure that the laser scattering detection system of the optical plane surface defect of the present invention comprises:

[0032] An X-Y precision stepping platform 12 for placing the optical element 9 to be tested;

[0033] In the normal direction of the X-Y precision stepping platform 12 and above the optical element 9 to be measured, a second plane reflector 8, a scattered light collecting diaphragm 14, and a scattered light collecting objective lens are sequentially arranged on the same optical axis from bottom to top 15. An optical fiber group collector 16, which is located at the rear focal plane of the scattered light collecting objective lens 15, and the multi-cha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com