Method, tool, and apparatus for manufacturing a semiconductor device

一种半导体、工具的技术,应用在制造半导体器件领域,能够解决去除沉积膜、半导体基板或生产线污染、难加热半导体基板等问题,达到防止金属污染、接触面积增加的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

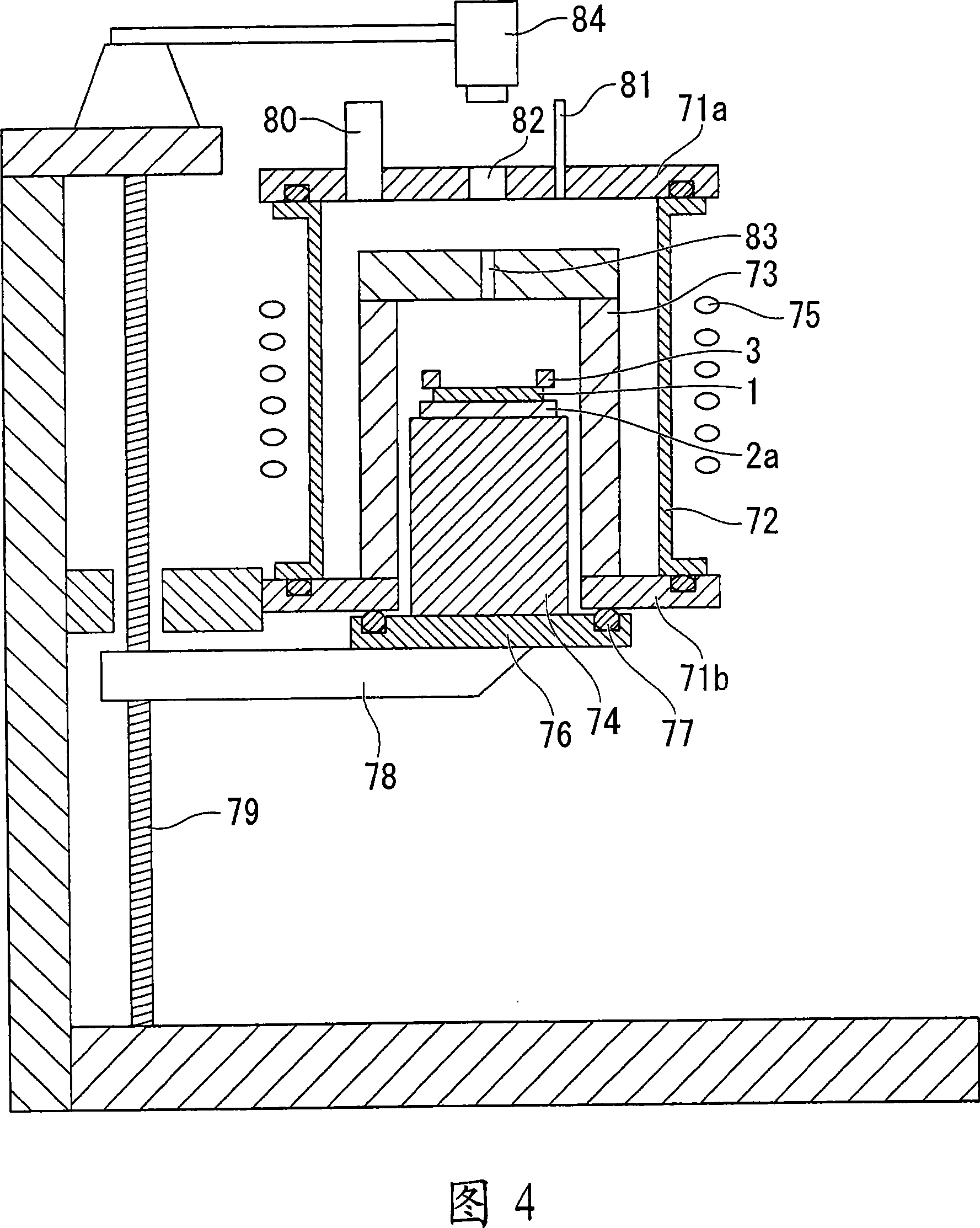

[0082] Hereinafter, embodiments according to the present invention will be described with reference to the drawings.

[0083] Hereinafter, a first embodiment will be described in which the semiconductor substrate is heated in the state shown in FIGS. 1 to 3.

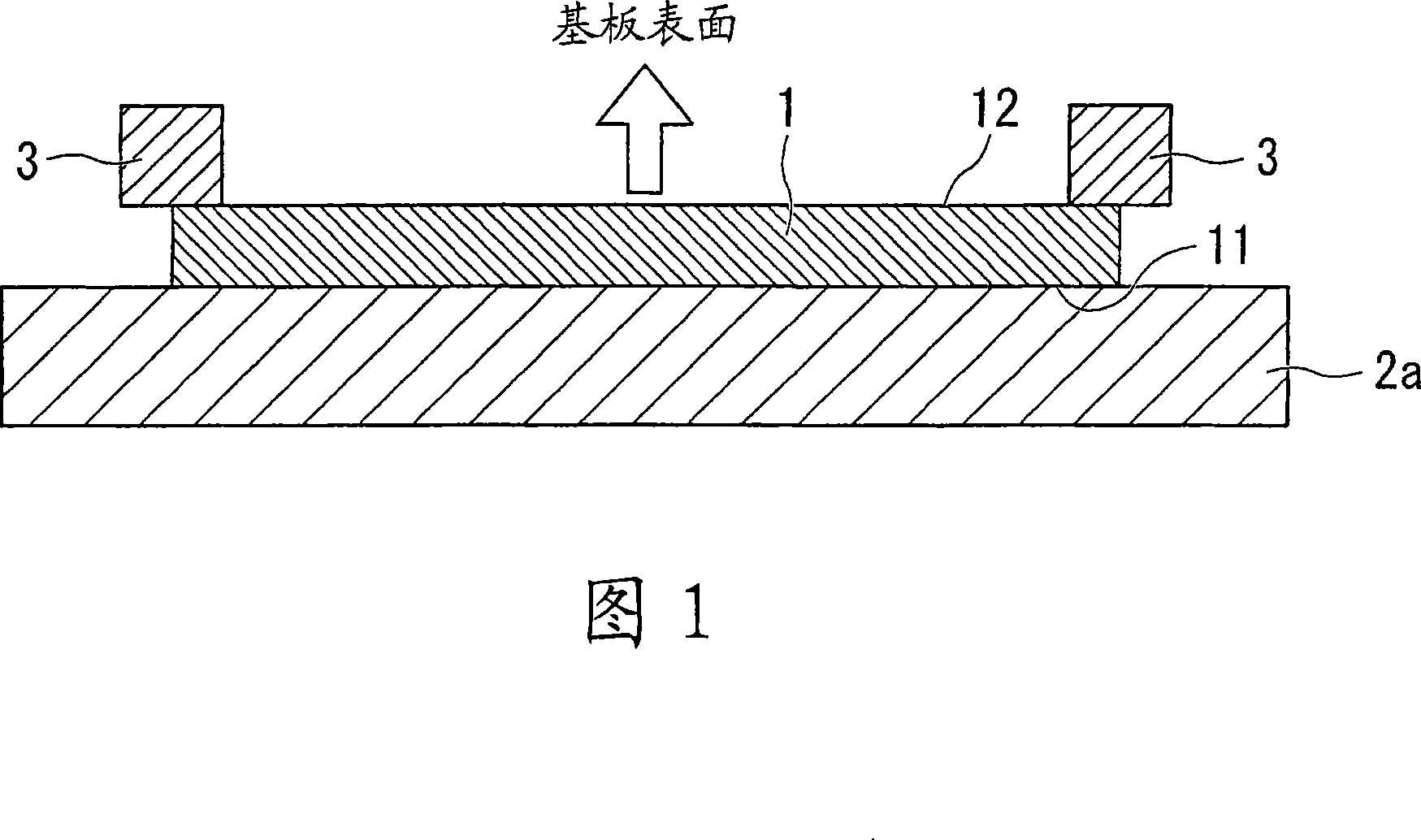

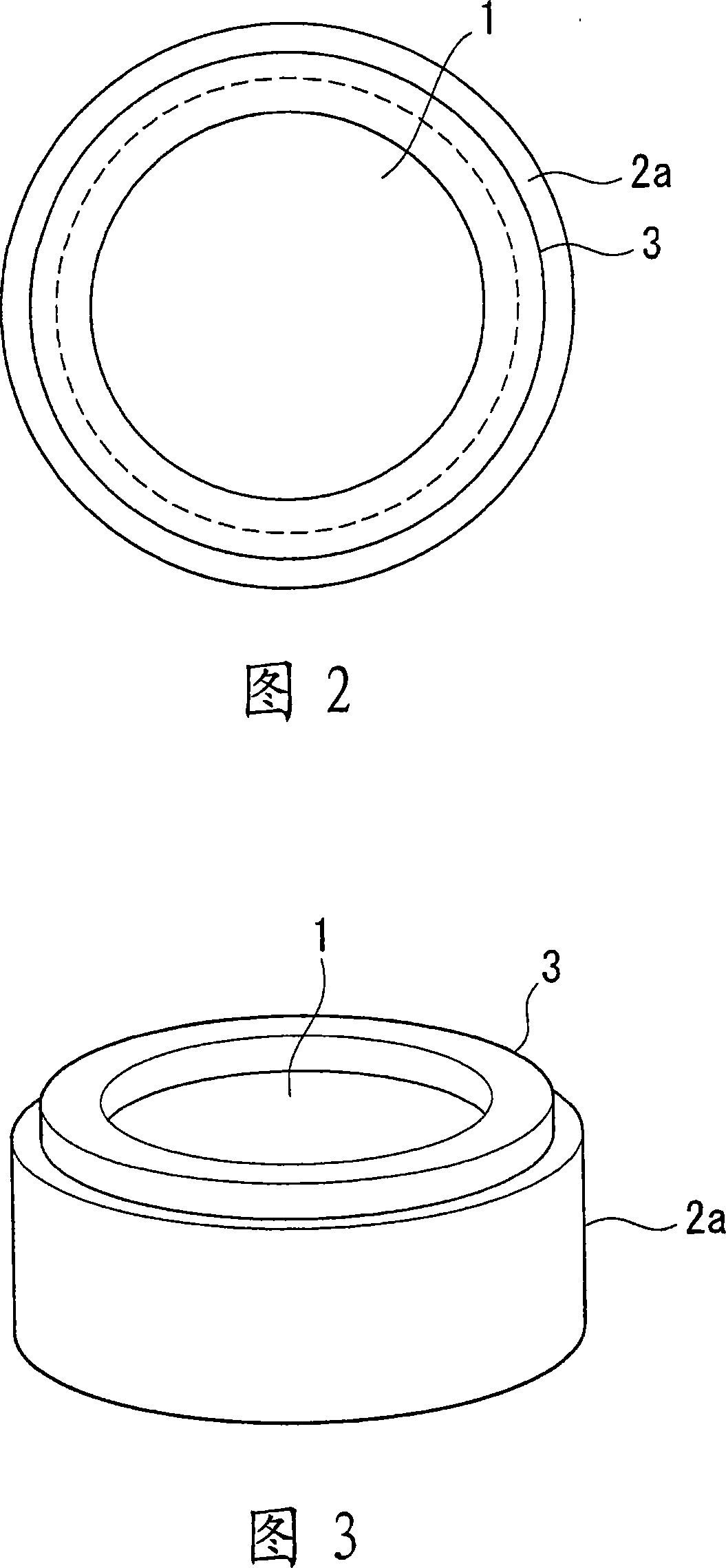

[0084] FIG. 1 is a cross-sectional view showing a tool and a WBG substrate (as a semiconductor substrate) in the first embodiment. Fig. 2 is a plan view showing a tool and a WBG substrate in the first embodiment. Fig. 3 is a perspective view showing a tool and a WBG substrate in the first embodiment.

[0085] The WBG substrate 1 is placed on the susceptor 2a (the main component of which may be graphite (C)) in such a way that the main surface 11 of the WBG substrate 1 faces the susceptor 2a. A heavy stone 3 is placed on the other main surface 12 of the WBG substrate 1. According to the present invention, the above-mentioned base 2a and heavy stone 3 serve as tools for manufacturing semiconductor devices.

[0086] Due to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com